Resin-coated carrier and preparation method therefor, and bi-component developing agent

A resin coating, carrier technology, applied in the development agent, electrography, optics, etc., can solve the problems of durability, insufficient carrier adhesion inhibition, toner charge fluctuation, uneven distribution, etc., to reduce the carrier Adhesion, excellent effect, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Preparation of resin-coated carrier 1

[0043] Coating Dispersion Formula:

[0044] Silane coupling agent (solid content 98wt%, OFS-6020: American DowCorning): 10 parts

[0045] Silicone resin solution (solid content 70wt%, KR251: Japan ShinEtsu): 86 parts

[0046] Acrylic resin solution (solid content 60wt%, PMMA: Mw=8*10 4 ): 50 copies

[0047] Conductive carbon black (model: VXC72, manufacturer: American CABOT): 8 parts

[0048] Silica particles (surface treated with polydimethylsiloxane, number average primary particle size 160nm): 1 part

[0049] Toluene: 640 parts

[0050] Weigh and mix each component according to the above formula, and disperse for 15 minutes using a high-speed disperser (model: T18, manufacturer: IKA, Germany) to obtain a coating layer dispersion. Get 12 parts of coating layer dispersion liquid and drop into 100 parts of magnetic core material (volume median diameter D 50 : 36 μm, saturation magnetization: 76 emu / g), coating on a kneader ...

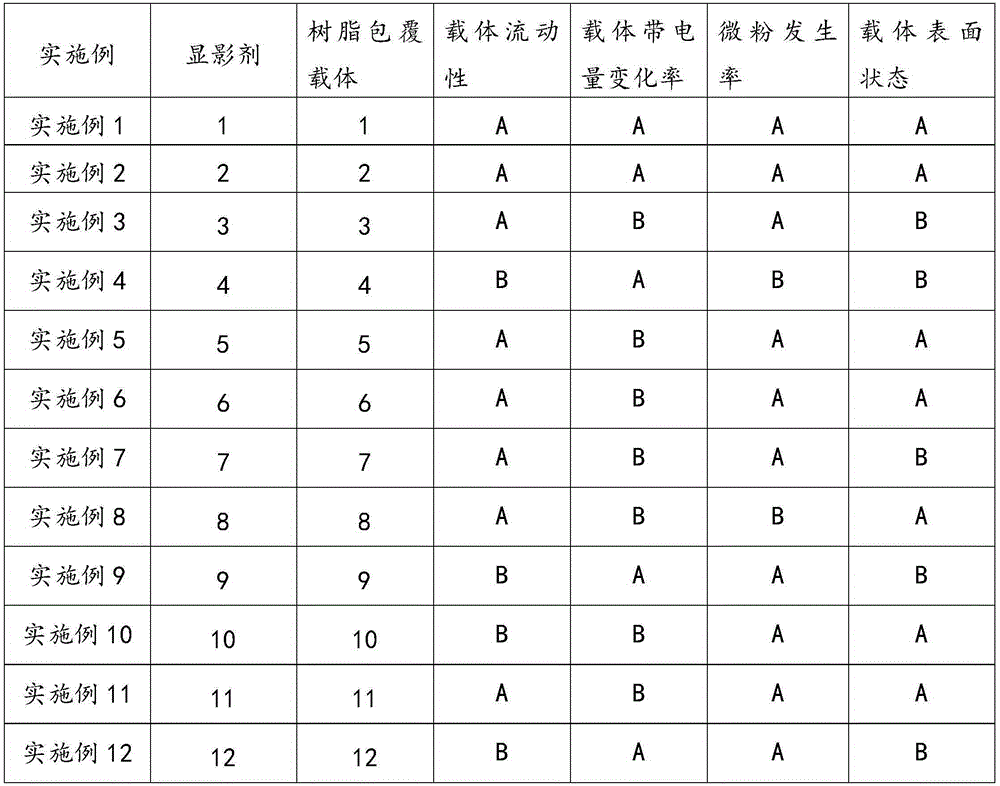

Embodiment 1~12

[0181] The above-mentioned "resin-coated carriers 1-12" and "toner" were mixed in the following manner to prepare the two-component "developers 1-12" of the example. 93 parts of carrier and 7 parts of toner were mixed in a mixer for 10 minutes to prepare a two-component developer.

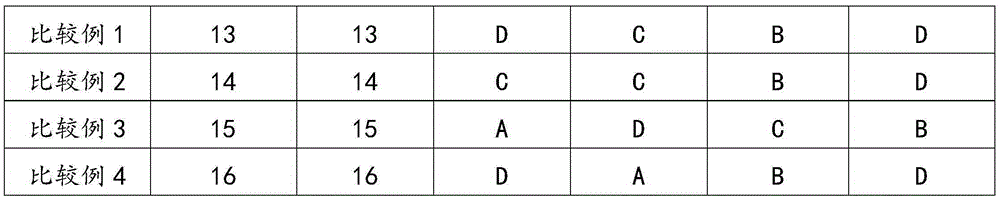

Embodiment 13

[0188] Mix 7 parts each of yellow toner, magenta toner, cyan toner, and black toner with 93 parts of resin-coated carrier 1 respectively, and mix each in a mixer for 10 minutes to prepare a 4-color double-pack Separate developer. At the same time, yellow toner, magenta toner, cyan toner, and black toner are used as supplementary developers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com