Comprehensive utilization method for resources of waste lead storage battery

A technology for waste lead-acid batteries and lead-acid batteries, applied to lead-acid batteries, lead-acid battery electrodes, battery electrodes, etc., which can solve the problems of high energy consumption, long time consumption, and increased preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

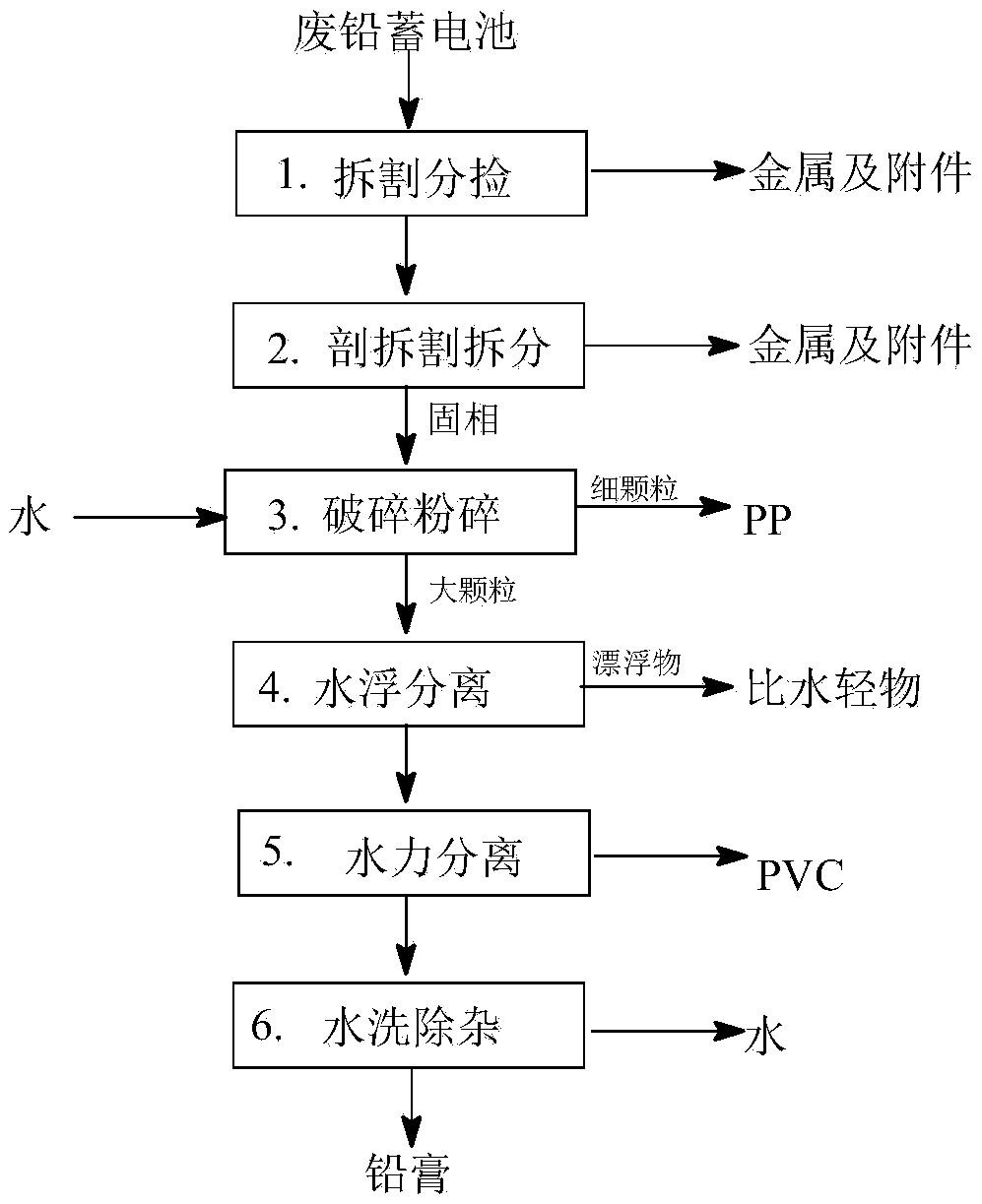

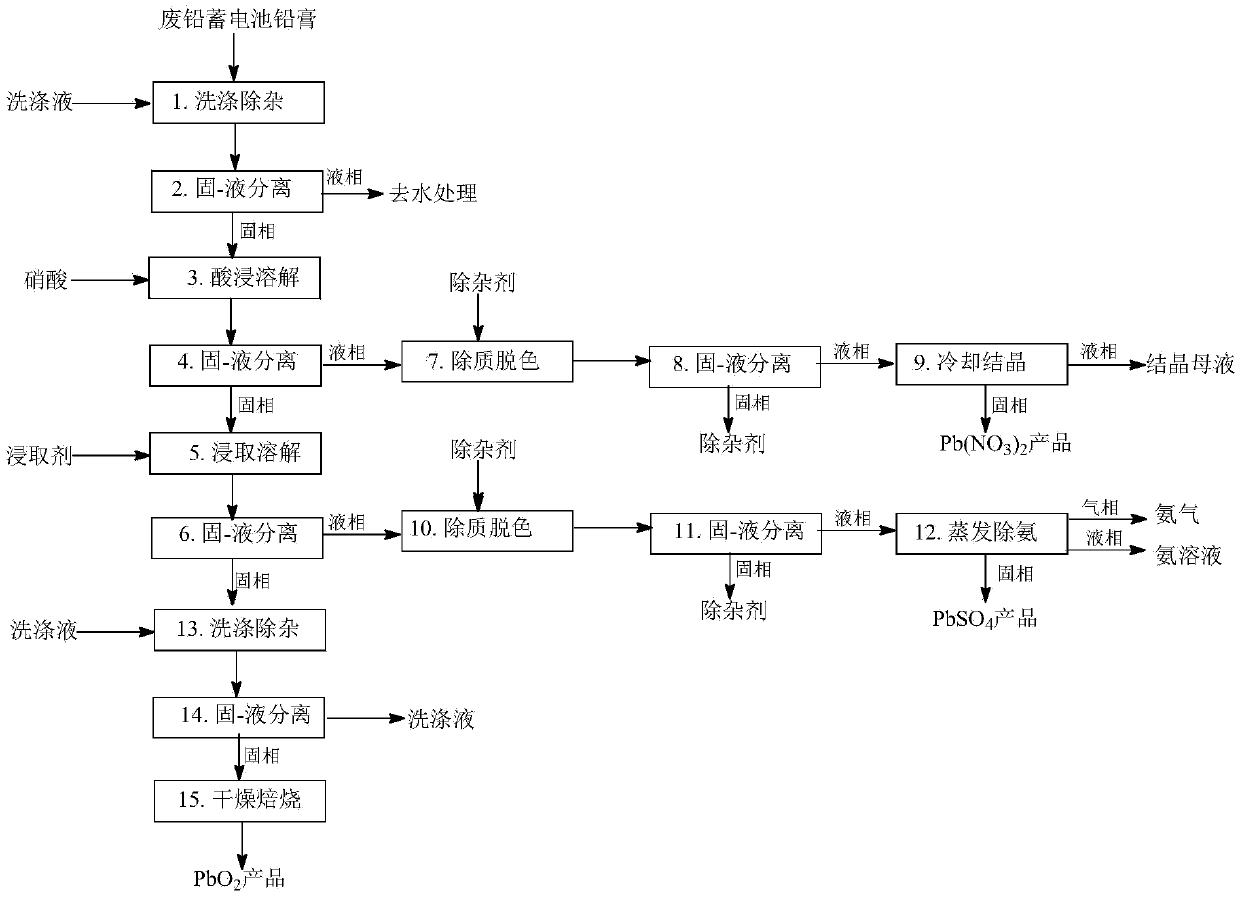

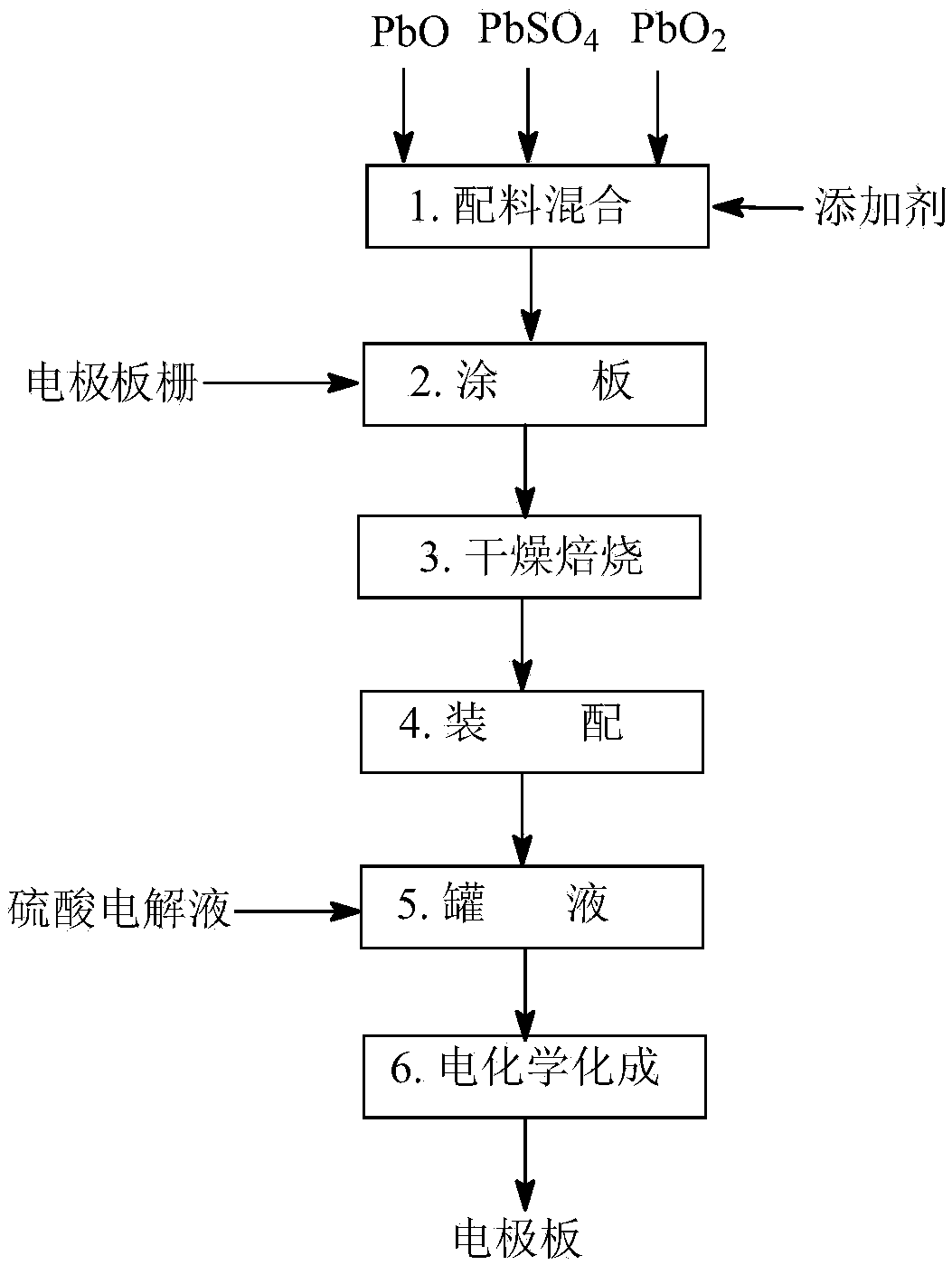

[0166] Such as Figure 1-3 As shown, a process method for resource utilization of waste lead-acid batteries, especially a process technology related to resource utilization of lead-containing materials in waste lead-acid batteries, mainly consists of "separation of lead paste in waste lead-acid batteries", "using Separation and Preparation of PbSO from Lead Paste as Raw Material 4 , PbO, PbO 2 " and " the preparation of lead storage battery electrode " three parts. It is characterized in that described method step is as follows:

[0167] Part1 Separation of lead paste in waste lead-acid batteries

[0168] Waste lead-acid batteries are composed of metal lead and lead alloy, other metal sheets, lead paste (lead monoxide, lead sulfate, lead dioxide, etc.), sulfuric acid, separator, tank materials (plastic, rubber, etc.), and need Various fragmentary parts are recovered through battery dismantling technology and other separation technologies. Generally, unit operations such as...

Embodiment 2

[0202] Such as Figure 1-3 As shown, a process method for resource utilization of waste lead-acid batteries, especially a process technology related to resource utilization of lead-containing materials in waste lead-acid batteries, mainly consists of "separation of lead paste in waste lead-acid batteries", "using Separation and Preparation of PbSO from Lead Paste as Raw Material 4 , PbO, PbO 2 " and " the preparation of lead storage battery electrode " three parts. It is characterized in that described method step is as follows:

[0203] Part1 Separation of lead paste in waste lead-acid batteries

[0204] Using waste lead storage batteries as raw materials, the waste lead storage batteries are preliminarily separated to obtain lead paste containing lead monoxide, lead sulfate, and lead dioxide, and the recycling of other materials is the same as the technical solution in embodiment 2.

[0205] Part2 Separation and Preparation of PbSO Using Lead Paste as Raw Material 4 , Pb...

Embodiment 3

[0231] Such as Figure 1-3 As shown, a process method for resource utilization of waste lead-acid batteries, especially a process technology related to resource utilization of lead-containing materials in waste lead-acid batteries, mainly consists of "separation of lead paste in waste lead-acid batteries", "using Separation and Preparation of PbSO from Lead Paste as Raw Material 4 , PbO, PbO 2 " and " the preparation of lead storage battery electrode " three parts. It is characterized in that described method step is as follows:

[0232] Part1 Separation of lead paste in waste lead-acid batteries

[0233] Using waste lead storage batteries as raw materials, the waste lead storage batteries are preliminarily separated to obtain lead paste containing lead monoxide, lead sulfate, and lead dioxide, and the recycling of other materials is the same as the technical solution in embodiment 2.

[0234] Part2 Separation and Preparation of PbSO Using Lead Paste as Raw Material 4 , Pb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com