Fault monitoring and fault-tolerant control method for electric vehicle driving system

A drive system, fault monitoring technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention is described in detail below in conjunction with accompanying drawing:

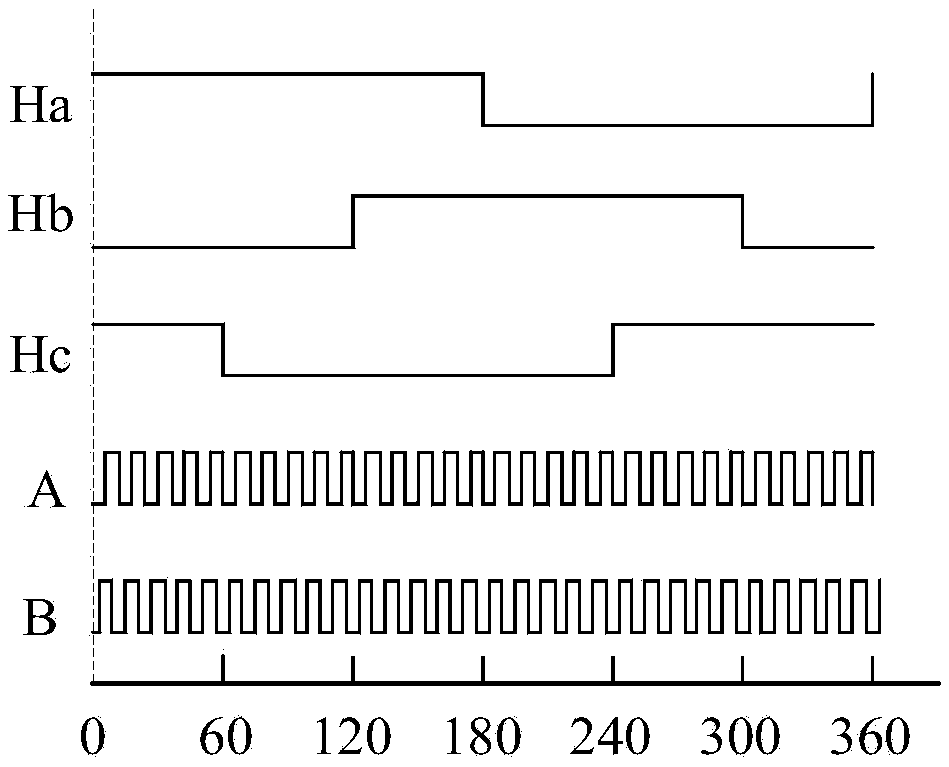

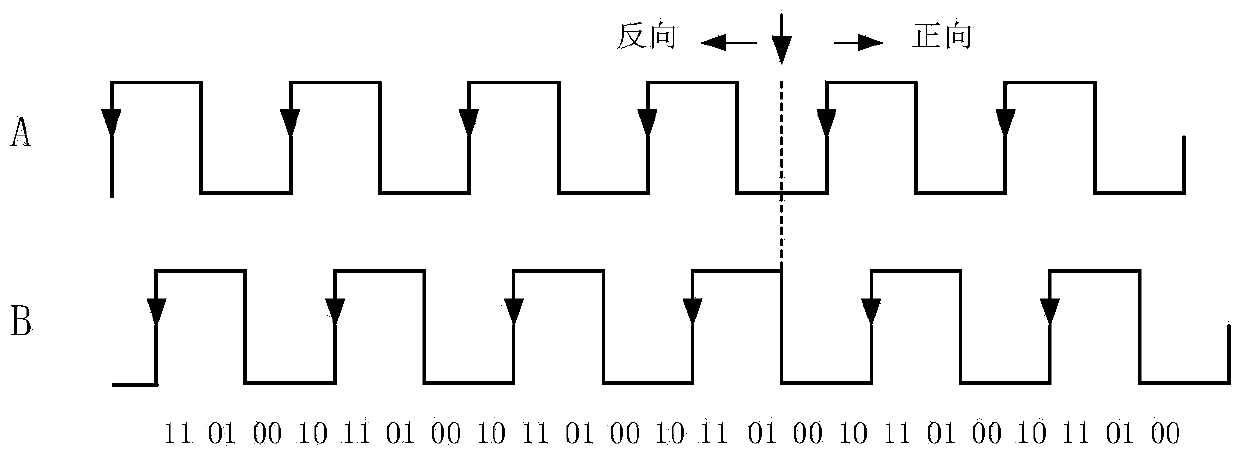

[0063] The present invention is aimed at the failure detection of the failure of the incremental signals A and B of the magnetoelectric hybrid encoder in the drive system of the permanent magnet synchronous motor for electric vehicles, and uses the absolute position signals HA, HB and HC to measure the angular position of the rotor of the permanent magnet synchronous motor. Estimated fault-tolerant control method.

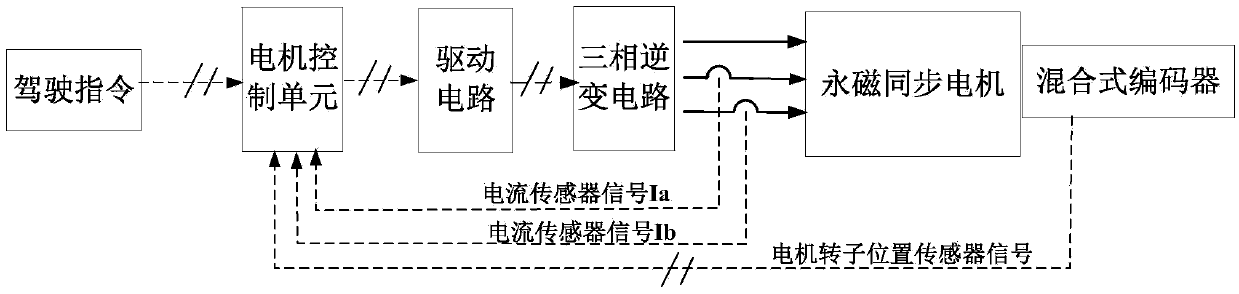

[0064] refer to figure 1 , The permanent magnet synchronous motor drive system for electric vehicles described in the present invention includes six parts: a motor control unit, a drive circuit, a three-phase inverter circuit, a permanent magnet synchronous motor and a magnetoelectric hybrid encoder. The motor control unit is used to collect various information such as driving command signals, position sensors, current sensors, and voltage sensors to obtain rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com