Production equipment and production method of quick-frozen corns

A production equipment and corn technology, which is applied in threshing equipment, seed preservation by freezing/cooling, food processing, etc., can solve the problems of many manual operation steps, low degree of automation, and low production efficiency, and achieve the reduction of manual operation steps, The effect of high degree of automation and easy labor for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

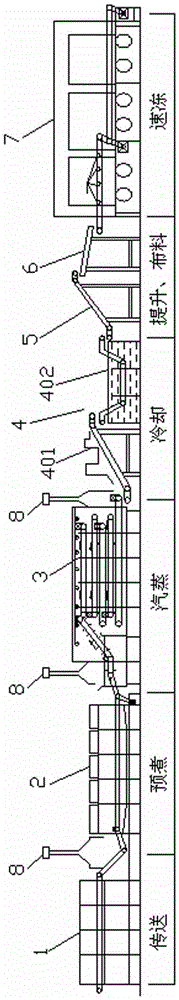

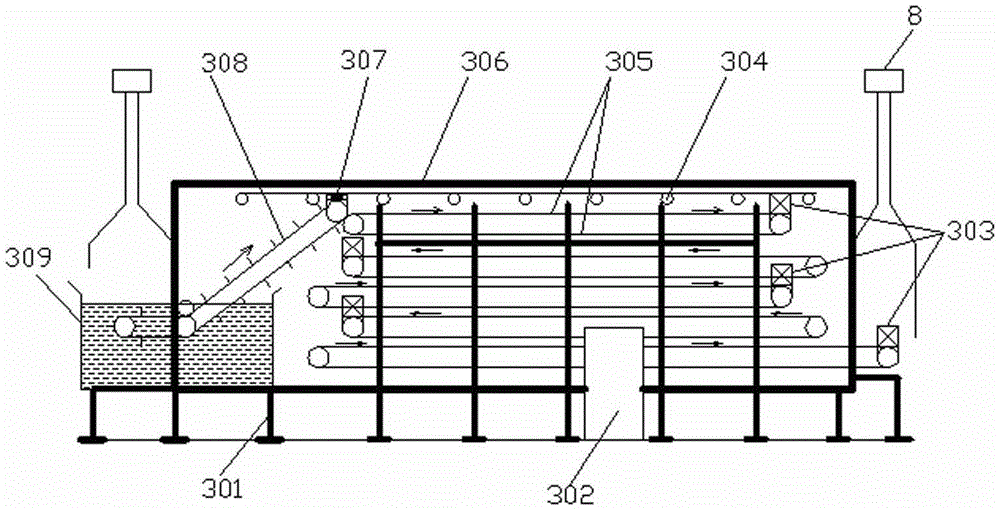

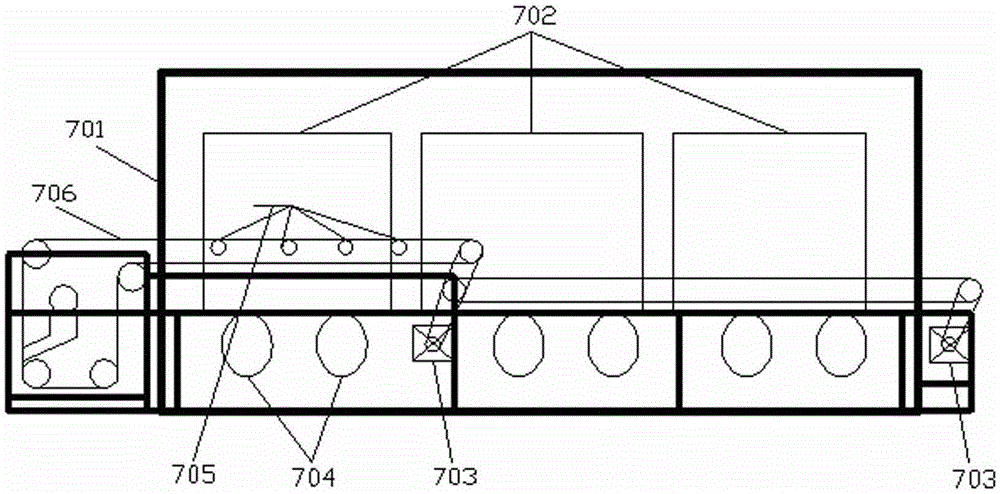

[0034] like Figure 1~3 Shown, a kind of production equipment of quick-frozen corn, comprises peeling machine, cutting head and tail cutting machine, beard removal cleaning machine, conveyer 1 and cutting machine, including the sequential arrangement between said conveyer 1 and cutting machine There are pre-cooking machine 2, steaming machine 3, cooling machine 4, hoist 5, vibrating distributing machine 6 and quick-freezing machine 7, the peeling machine, head and tail cutting machine, beard removal cleaning machine, conveyor 1, pre-cooking machine Machine 2, steaming machine 3, cooling machine 4, hoist 5, vibrating distributing machine 6, quick-freezing machine 7 and cutting machine are arranged in sequence to form a production line, and conveyor 1, precooking machine 2, steaming machine 3, cooling Machine 4, hoist 5, vibrating distributing machine 6, quick-freezing machine 7 and section cutting machine are all provided with conveying device inside, and any adjacent two conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com