Method for treating ammonium chloride wastewater

A technology for ammonium chloride and waste water, applied in chemical instruments and methods, multi-stage water/sewage treatment, calcium/strontium/barium chloride, etc., can solve the problems of low treatment efficiency and the utilization rate of other polluting by-products, Reach the effect of saving the cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

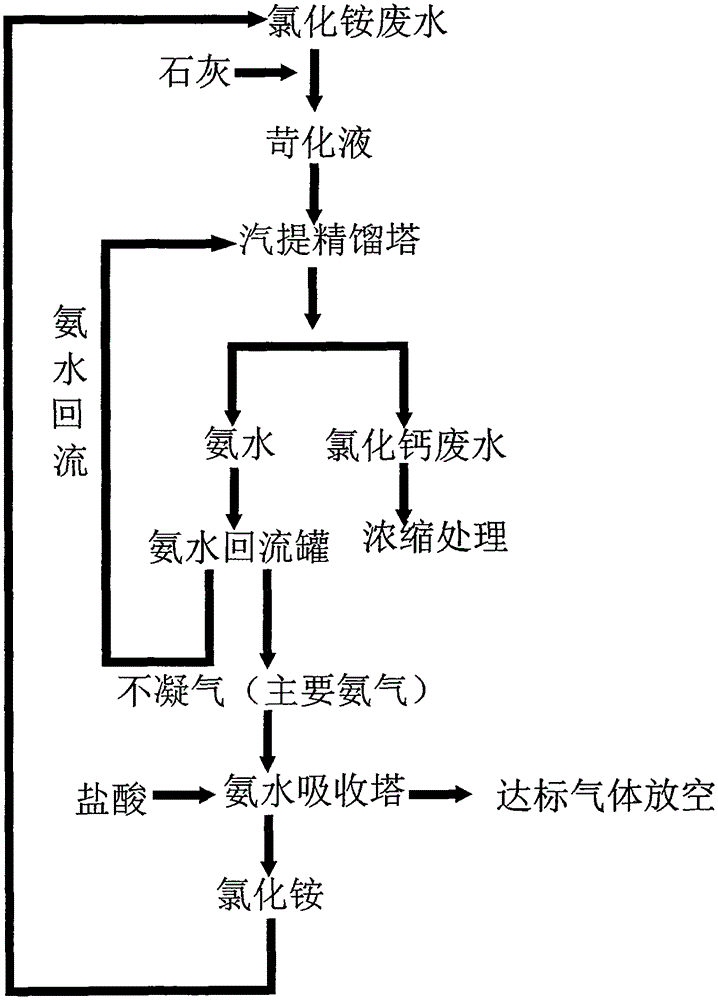

[0026] A method for treating ammonium chloride waste water, the concrete steps are as follows:

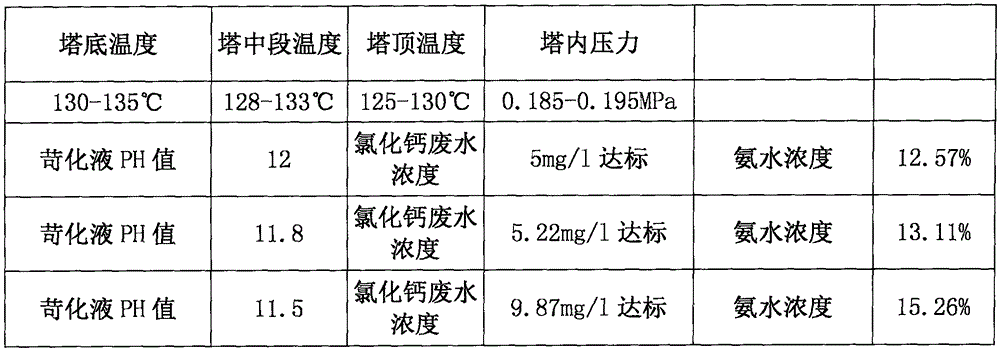

[0027] Step 1, adding lime and ammonium chloride to the ammonium chloride wastewater, and causticizing the ammonium chloride wastewater to obtain a causticizing solution, ensuring that the pH of the causticizing solution is 11.5-12.0;

[0028] Step 2, carrying out plate and frame filter press filter to the causticizing liquid obtained in step 1, so that the causticizing liquid filtrate does not contain solid residue;

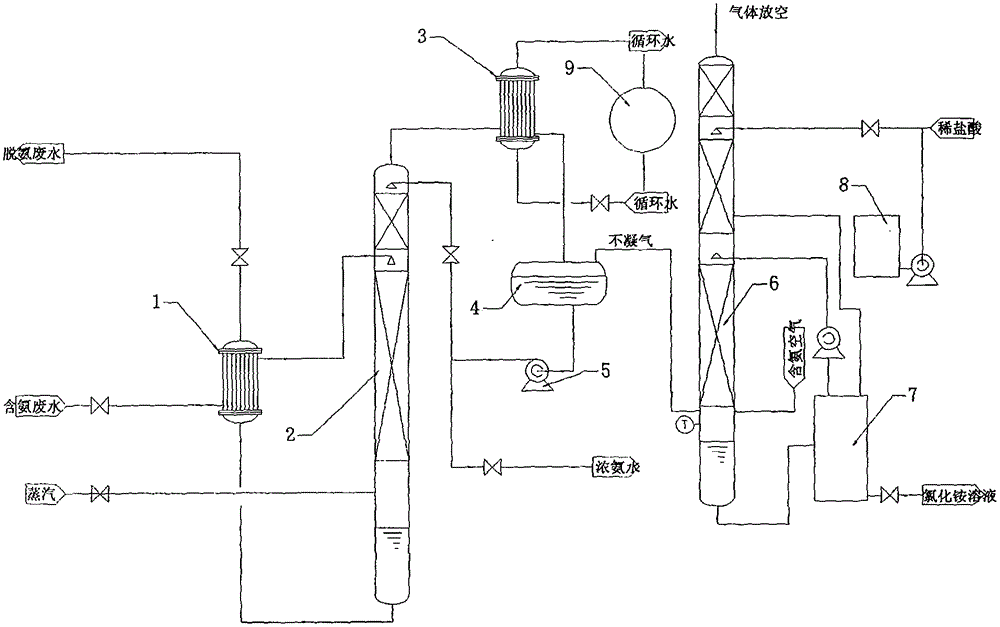

[0029] Step 3, the causticizing liquid filtered in step 2 enters the stripping and rectifying tower 2 from the top of the stripping and rectifying tower 2, the direction is from top to bottom, and the steam enters from the bottom of the stripping and rectifying tower 2, and the steam is adjusted by adjusting the stripping and rectifying tower. The temperature and pressure in the rectification tower 2 make the ammonia water be separated from the causticizing liquid, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com