Ceramic material and preparation method thereof

A ceramic material and raw material technology, which is applied in the field of ceramic substrate materials with high body resistance characteristics, can solve problems such as poor sintering performance, low thermal expansion coefficient, and difficult densification, and achieve improved ceramic compactness, low softening temperature, and lower firing temperature. Effect

Active Publication Date: 2016-03-09

UNIV OF ELECTRONICS SCI & TECH OF CHINA

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

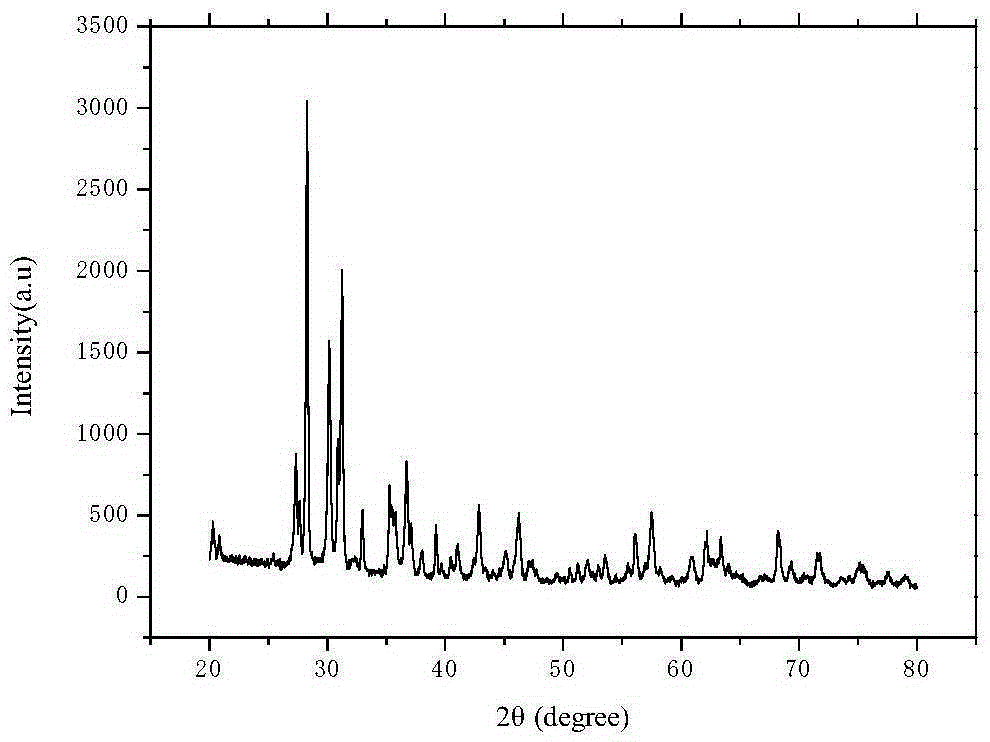

[0006] Common magnesia porcelain is mostly made of mineral materials, with many miscellaneous phase components, and MgSiO 3 There will be a phase change, MgSiO 3 There are four isomers, Proto-enstatile (enstatite) is a high-temperature form, has good mechanical strength and low thermal expansion coefficient, and is commonly used on circuit substrates; Ortho-enstatile (orthogonal pyroxene), Clino- enstaticile (monoclinopyroxene) and Monoclinicamphibole (monoclinic amphibole) are MgSiO 3 low-temperature form; orthorhombic pyroxene (α-MgSiO 3 ) and monoclinic pyroxene (β-MgSiO 3 ) is interactively transformed, compared to Mg 2 SiO 4 Ceramic, MgSiO 3 Ceramics have a lower dielectric constant, but have poor sinterability and are difficult to densify

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

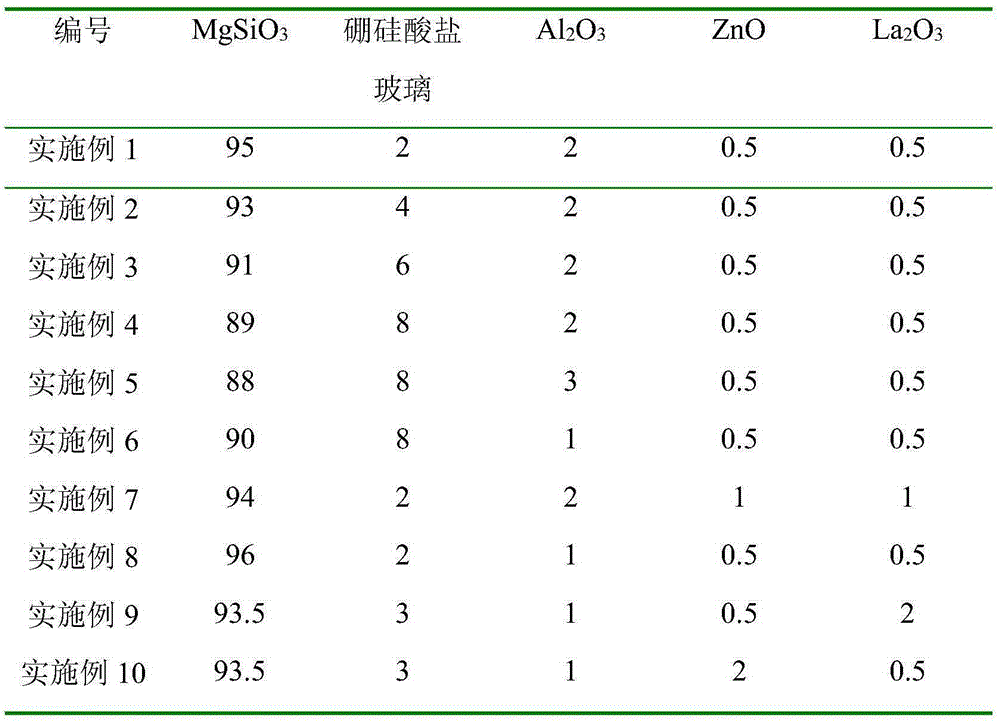

[0025] The present invention adopts MgO with a purity greater than 99.5%, 99.5% SiO 2 As raw material for the preparation of MgSiO 3 , greater than 99.5% CaCO 3 、H 3 BO 3 , SiO 2 、LiCO 3 、Na 2 O, K 2 O, Al 2 o 3 etc. to prepare molten glass with a purity greater than 99.5% Al 2 o 3 , ZnO, La 2 o 3 Doping etc., the specific implementation method is as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Login to View More

Abstract

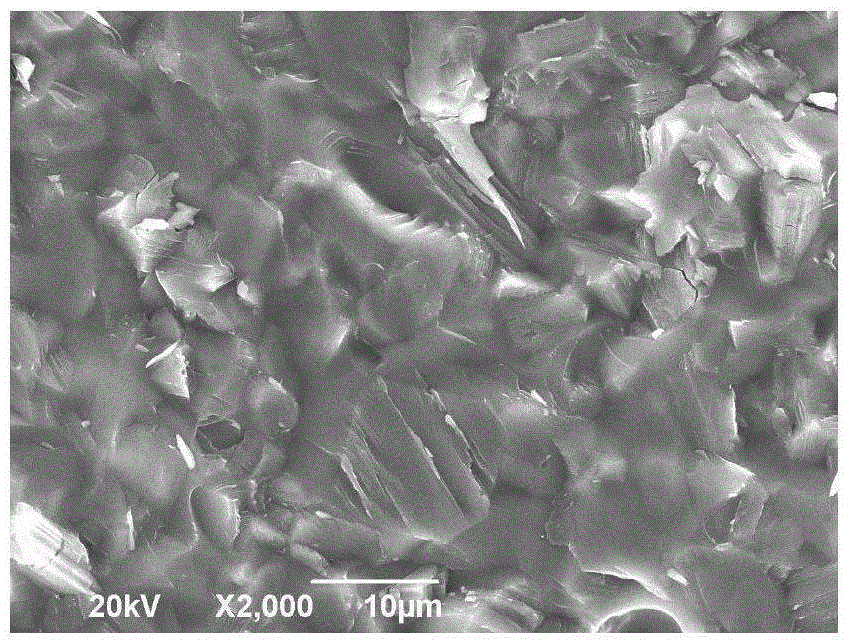

The invention discloses a ceramic material and a preparation method thereof, and belongs to the technical field of electronic functional materials and devices. The ceramic material is prepared by the following steps: mixing a main crystalline phase material and a doping phase material through ball milling, then subjecting the mixture to dry pressing and moulding, and finally sintering. The ceramic material comprises the following components in percentage by weight: 85 to 97% of MgSiO3, 1 to 8% of borosilicate glass, 1 to 3% of Al2O3, 0.5 to 2% of ZnO, and 0.5 to 2% of La2O3; wherein the MgSiO3 is the main crystalline phase, and the doping phase comprises borosilicate glass, Al2O3, ZnO, and La2O3. Compared with the similar ceramic material in the prior art, the provided ceramic material has excellent properties: the ceramic-forming density (rho) is larger than 2.7 g / cm3, the dielectric constant [epsilon]<r> is low (less than 7.0), and the flexure strength is high (higher than 150 MPa). The preparation method has the advantages of simple technology, low price, and good production repeatability. The low-cost, massive, and stable production of MgSiO3 ceramic substrate material becomes possible.

Description

technical field [0001] The invention belongs to the technical field of electronic information functional materials and devices, and specifically relates to a ceramic substrate material with low dielectric constant, high ceramic density, high bending strength and high body resistance. It can be used to make components such as circuit substrates, ceramic dielectric substrates, dielectric filters, and dielectric antennas in modern electronics and communication technologies. Background technique [0002] Due to the strong demand in the consumer electronics market, higher technical requirements are constantly being put forward, such as high-speed information transmission, integrity, multi-functionality and miniaturization of products. In traditional electronic product applications, most of the application frequencies are concentrated below 1GHz, and PCB and terminal manufacturers designers tend to ignore the negative impact of the high dielectric constant of the substrate materia...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/16C04B35/622C03C12/00

Inventor 孙成礼张树人周晓华李波

Owner UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com