Iron humate-microbe composite soil pollution repairing agent and preparation method thereof

A technology of iron humic acid and composite restoration, which is applied in soil conditioning materials, chemical instruments and methods, fertilizer mixtures, etc., to achieve the effects of small environmental risks, low production costs, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation method of a binary composite restoration agent of iron humate and humus-reducing bacteria, comprising the steps of:

[0038] S1: extract humic acid;

[0039]S2: preparing iron humate;

[0040] S3: strains cultured in shake flasks;

[0041] S4: fermenting and preparing bacterial agent;

[0042] S5: Mix to form a repairing agent.

[0043] The preparation of the binary composite restoration agent is carried out by using the above method, which specifically includes:

[0044] Step 1 Extraction of humic acid: Add 100g of raw materials rich in humic acid such as peat soil, lignite or weathered coal into 150-200ml of 0.1-0.15M NaOH solution, extract at 150-200rmp for 12-24h, and extract at 4000-6000g Centrifuge for 10-20min for solid-liquid separation; add 150-200ml of 0.1-0.15M NaOH to the solid phase again, extract at 150-180rmp for 12-24h, repeat this step 2-4 times; combine the liquid phases extracted multiple times , and then add 1-3M HCl to acidify to ...

Embodiment 1

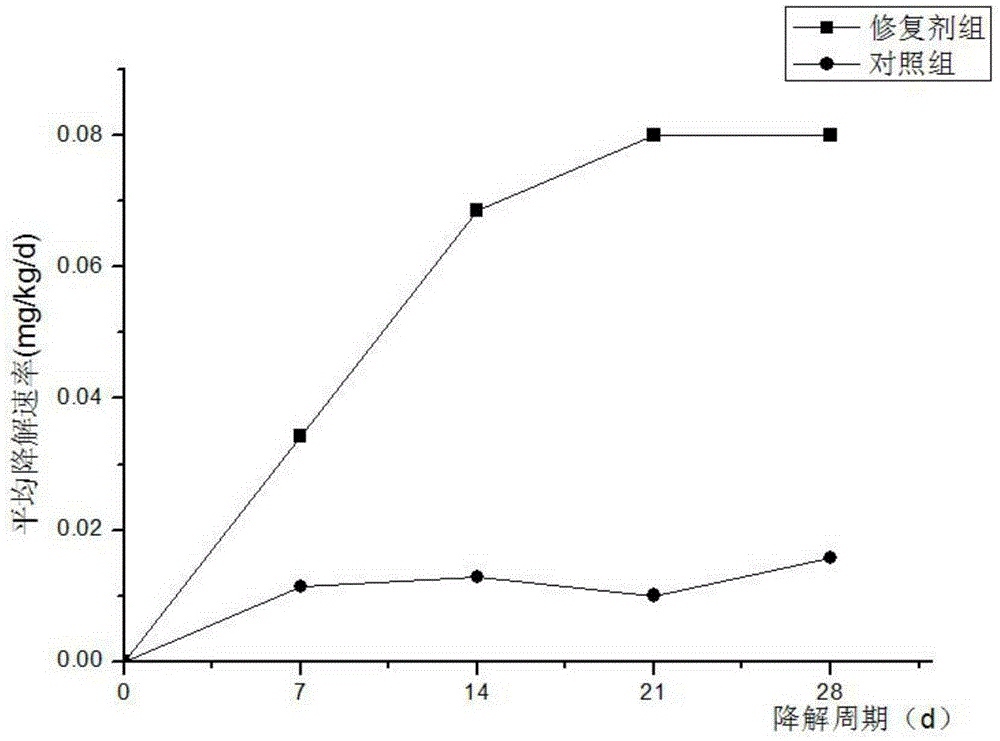

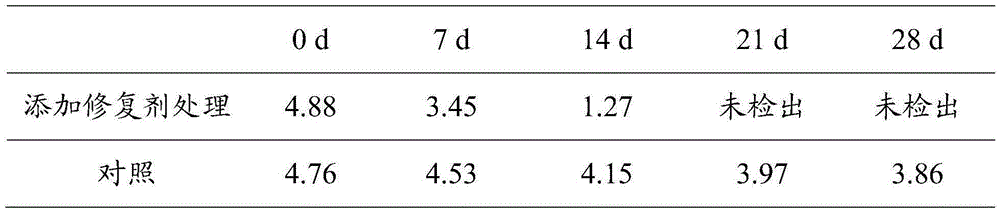

[0050] Preparation of peat soil ferric humate and Shewanella putrefaction complex organic pollution remediation agent

[0051] (1) Humic acid extraction: add 100g of peat soil to 150ml of 0.15M NaOH solution, extract at 150rmp for 24h, and centrifuge at 6000g for 10min to separate the solid from the liquid; The liquid phases were combined, and then acidified by adding 2M HCl until the pH was 1.92 to obtain a flocculent precipitate, which was lyophilized and set aside.

[0052] (2) Preparation of humic acid iron: adding 1.5g of extracted humic acid to 500ml concentration of 0.02M Na 4 P 2 o 7 In the solution, after fully mixing, centrifuge at 14000g for 15min to separate the solid phase and discard the solid phase precipitate; add 7.5mM Fe(SO 4 )·7H 2 O, adjust the pH of the mixed solution to 7.0; then put the mixed solution in a polypropylene plastic container, keep it at 35°C for 5 days, then centrifuge at 15,000g for 20 minutes, discard the liquid phase, and the obtained...

Embodiment 2

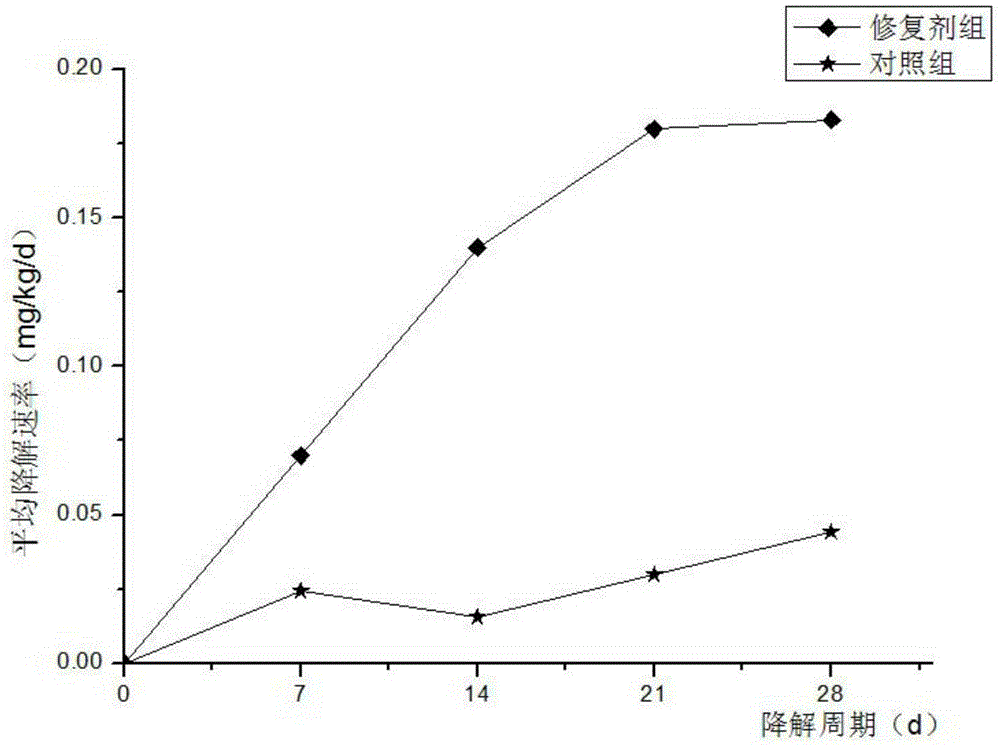

[0058] Preparation of compound organic pollution remediation agent of peat soil iron humate and Comamonas korean

[0059] (1) Humic acid extraction: Add 100g of peat soil to 200ml of 0.1M NaOH solution, extract at 200rmp for 12h, centrifuge at 6000g for 15min for solid-liquid separation; The liquid phases were combined, and then acidified by adding 3M HCl until the pH was 1.84 to obtain a flocculent precipitate, which was lyophilized and set aside.

[0060] (2) Preparation of humic acid iron: adding 2g of extracted humic acid to 1000ml concentration of 0.012M Na 4 P 2 o 7 In the solution, after fully mixing, centrifuge at 12000g for 20min to separate the solid phase and discard the solid phase precipitate; add 6mM Fe(SO 4 )·7H 2 O, adjust the pH of the mixed solution to 7.0; then put the mixed solution in a polypropylene plastic container, keep it at 30°C for 7 days, then centrifuge at 15,000g for 20 minutes, discard the liquid phase, and the obtained precipitate is ferric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com