Low-rank coal carbonization process and system

A technology of low-rank coal and dry distillation, which is applied in special forms of dry distillation, direct heating dry distillation, petroleum industry, etc. It can solve the problems of high semi-coke ash content, low safety and reliability, and poor quality, and achieve high quality, safe and reliable process High durability and low ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

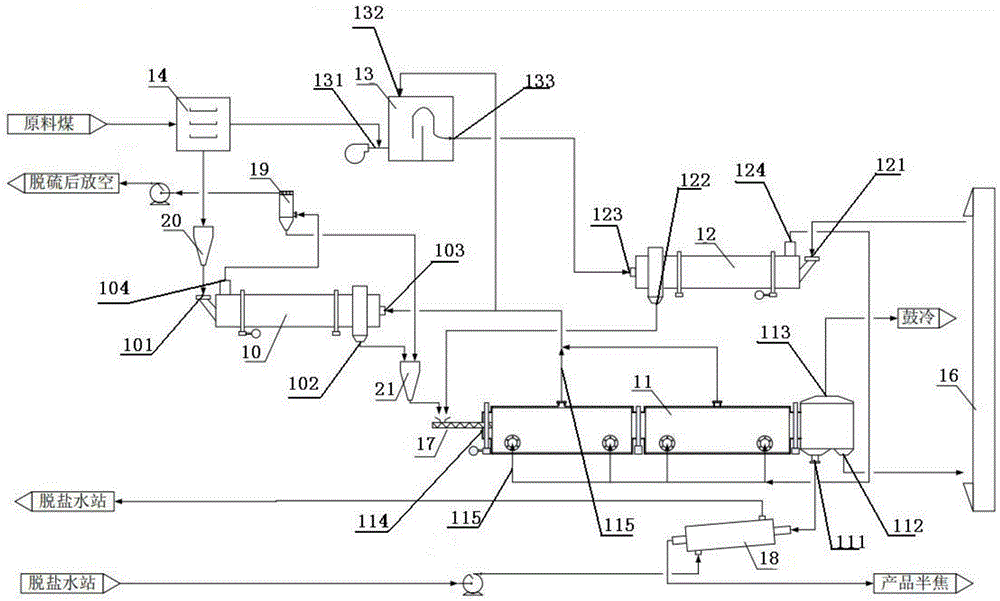

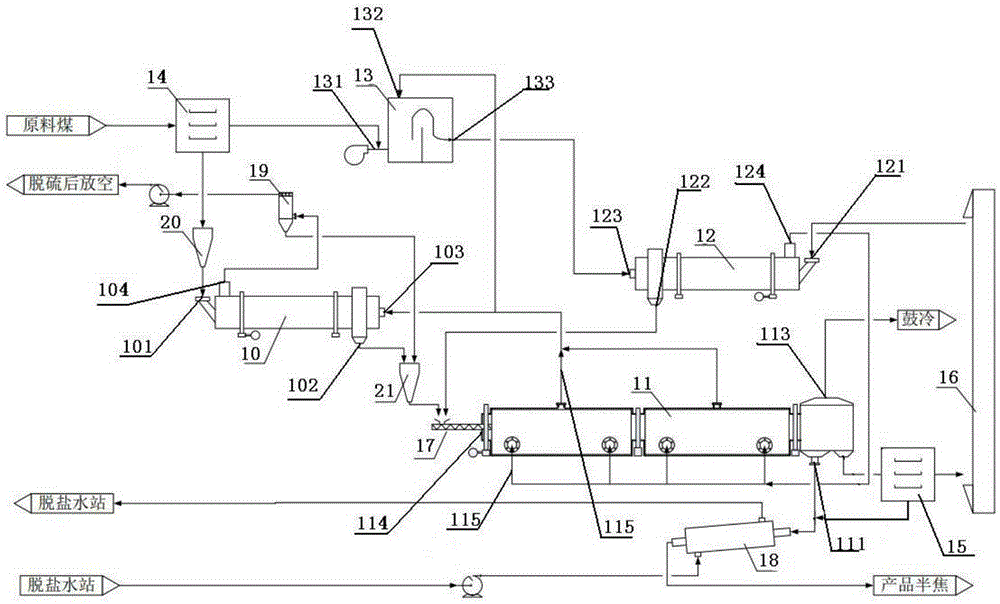

Method used

Image

Examples

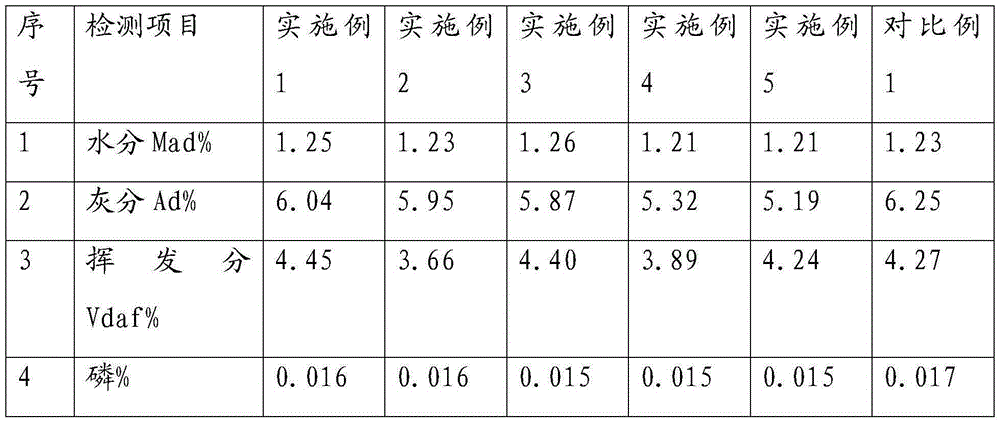

Embodiment 1

[0036] The low-rank coal dry distillation process described in this implementation includes the following steps:

[0037] (1) The raw coal is dried and preheated through a rotary drying furnace, and the raw coal is heated to 150° C. by direct contact or indirect contact, and the moisture content of the raw coal is reduced to below 8%, and then the raw coal is transported to the inlet of the rotary dry distillation furnace. The feed port is mixed with the hot semi-coke solid heat carrier at a mass ratio of 1:1.5. The hot semi-coke solid heat carrier is 750°C after being directly contacted with flue gas with a temperature of 1000°C and an oxygen content of 1.2%. hot semi-coke;

[0038] (2) Then the raw coal and the hot semi-coke solid heat carrier are transported together to the rotary carbonization furnace for carbonization, and the rotary carbonization furnace is subjected to indirect contact heating, and the temperature of the pyrolysis reaction is controlled to be 550 ° C. R...

Embodiment 2

[0040] The low-rank coal dry distillation process described in this implementation includes the following steps:

[0041] (1) Drying and preheating the raw coal through a rotary drying furnace, heating the raw coal to 245°C by direct or indirect contact, reducing the moisture content of the raw coal to below 5%, and then transporting the raw coal to the rotary carbonization furnace The feed port and the hot semi-coke solid heat carrier are mixed according to the mass ratio of 1:0.1. The hot semi-coke solid heat carrier is directly contacted with flue gas with a temperature of 1200 ° C and an oxygen content of 0.1% and the temperature is 1050 ℃ hot semi-coke;

[0042] (2) Then the raw coal and the hot semi-coke solid heat carrier are transported to the rotary carbonization furnace for carbonization, and the rotary carbonization furnace is subjected to indirect contact heating, and the temperature of the pyrolysis reaction is controlled to be 650 ° C. Minutes to generate semi-c...

Embodiment 3

[0044] The low-rank coal dry distillation process described in this implementation includes the following steps:

[0045] (1) Dry and preheat the raw coal through a rotary drying furnace, use high-temperature flue gas to directly contact and heat the raw coal to 180°C, reduce the moisture content of the raw coal to below 5%, and then transport the raw coal to the rotary dry distillation The feed port of the furnace is mixed with the hot semi-coke solid heat carrier at a mass ratio of 1:1. The hot semi-coke solid heat carrier is directly contacted and heated by flue gas with a temperature of 1100 ° C and an oxygen content of 1.0%. 800°C hot semi-coke, the particle size of the hot semi-coke is 4mm or more;

[0046] (2) Then the raw coal and the hot semi-coke solid heat carrier are transported to the rotary carbonization furnace for carbonization, and the high-temperature flue gas is used to indirect contact heating of the rotary carbonization furnace, and the temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com