A method of preparing stainless steel with antibacterial and anticancer properties

A stainless steel, performance technology, applied in metal material coating process, coating, etc., can solve the problems of poor water solubility, patient danger, environmental pollution, etc., and achieve the effect of low cost, good anti-cancer ability, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This scheme prepares the method for the stainless steel with antibacterial and anticancer performance, comprises the following steps:

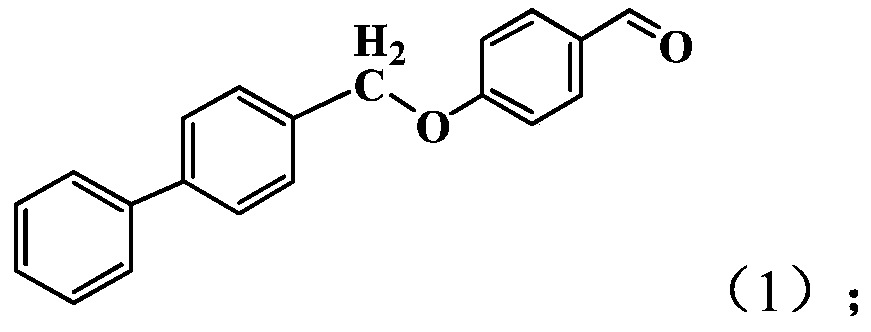

[0024] 1) Dissolve 4 parts by weight of 4-biphenylformaldehyde in 8 parts by weight of ethyl acetate, add 3 parts by weight of benzyl chloride, control 65 ° C, and stir for 2 hours to obtain a compound with formula (1), which is p( 4-phenylbenzyloxy)benzaldehyde;

[0025]

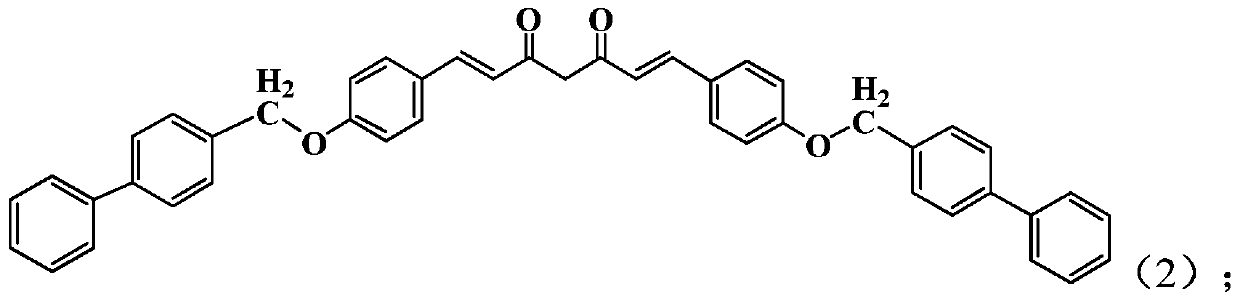

[0026] 2) Dissolve 3 parts by weight of p-(4-phenylbenzyloxy)benzaldehyde and 4 parts by weight of tributyl borate in 10 parts by weight of ethyl acetate, stir at room temperature for 5 minutes, then add 1 part by weight of acetylacetone and boron oxide 0.5 parts by weight of the mixed solution, continue to stir at room temperature for 30 minutes, then add 1 part by weight of n-butylamine, continue to stir for 3 hours, then stop stirring and let it stand for 15 hours, then add 10 parts by weight of hydrochloric acid with a concentration of 0.4mol / L, and stir at 60...

Embodiment 2

[0032] This scheme prepares the method for the stainless steel with antibacterial and anticancer performance, comprises the following steps:

[0033] 1) Dissolve 3 parts by weight of 4-biphenylformaldehyde in 6 parts by weight of ethyl acetate, add 2 parts by weight of benzyl chloride, control 60 ° C, stir and react for 2 hours, and obtain a compound with formula (1), which is para( 4-phenylbenzyloxy)benzaldehyde;

[0034]

[0035] 2) Dissolve 2 parts by weight of p-(4-phenylbenzyloxy)benzaldehyde and 2 parts by weight of tributyl borate in 5 parts by weight of ethyl acetate, stir at room temperature for 4 minutes, then add 0.5 parts by weight of acetylacetone and boron oxide 0.3 parts by weight of the mixed solution, continue to stir at room temperature for 20 minutes, then add 0.5 parts by weight of n-butylamine, continue to stir for 2 hours, then stop stirring and let it stand for 12 hours, then add 6 parts by weight of hydrochloric acid with a concentration of 0.3mol / L,...

Embodiment 3

[0041] This scheme prepares the method for the stainless steel with antibacterial and anticancer performance, comprises the following steps:

[0042] 1) Dissolve 8 parts by weight of 4-biphenyl formaldehyde in 15 parts by weight of ethyl acetate, add 5 parts by weight of benzyl chloride, control 80 ° C, stir and react for 3 hours, and obtain a compound with formula (1), which is para( 4-phenylbenzyloxy)benzaldehyde;

[0043]

[0044] 2) Dissolve 6 parts by weight of p-(4-phenylbenzyloxy)benzaldehyde and 8 parts by weight of tributyl borate in 15 parts by weight of ethyl acetate, stir at room temperature for 6 minutes, then add 1.5 parts by weight of acetylacetone and boron oxide 1.2 parts by weight of the mixed solution, continue to stir at room temperature for 40 minutes, then add 2 parts by weight of n-butylamine, continue to stir for 4 hours, then stop stirring and let stand for 18 hours, then add 15 parts by weight of hydrochloric acid with a concentration of 0.5mol / L, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com