Trivalent chromium hard chromium electroplating solution and application of trivalent chromium hard chromium electroplating solution in hard chromium electroplating

A technology of trivalent chromium and hard chromium, which is applied in the field of metal surface treatment, can solve the problems of sensitivity to impurity elements, difficulty in plating thickness, and plating of only a few microns, up to 20 to 30 microns, etc., to achieve good wear resistance , The appearance is smooth and white, and the effect of excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

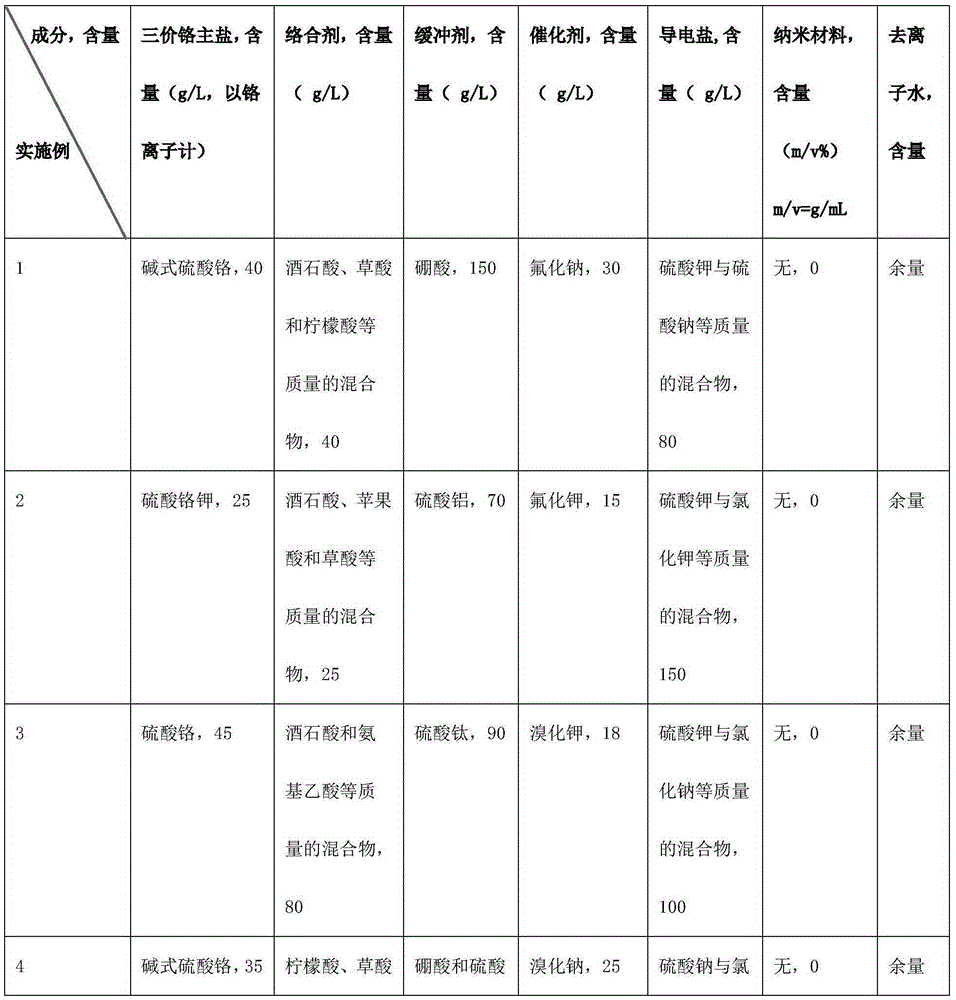

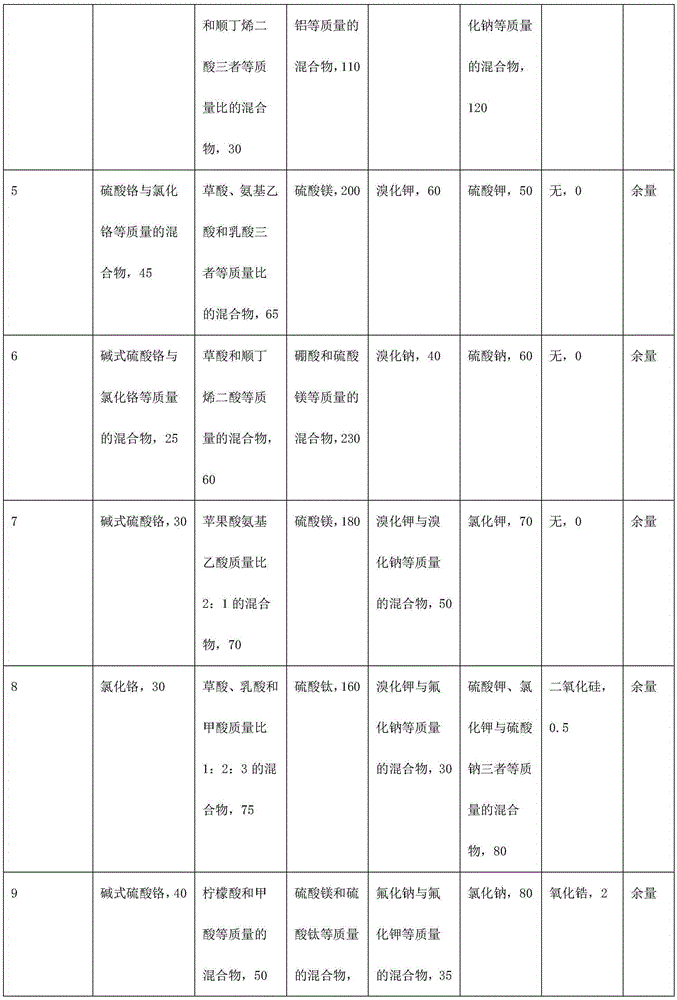

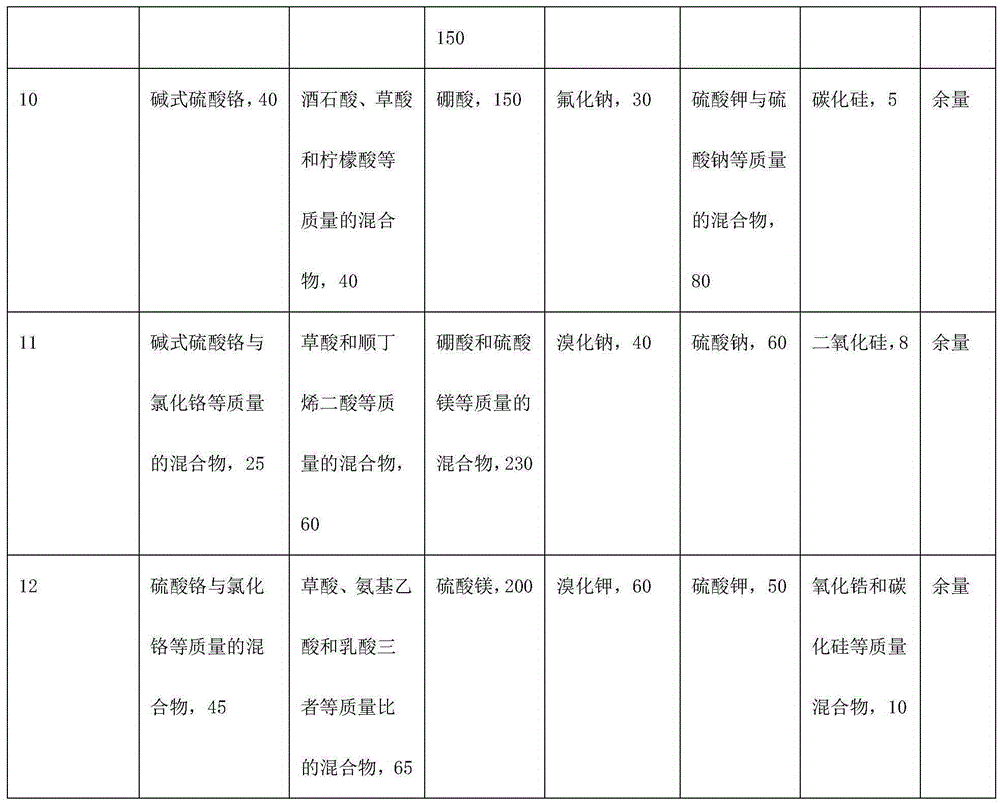

[0040] A kind of trivalent chromium hard chromium electroplating solution, its composition and content are listed in following table 1:

[0041] Table 1

[0042]

[0043]

[0044]

[0045] The pH value of above-mentioned each trivalent chromium hard chromium electroplating solution is listed in following table 2:

[0046] Table 2

[0047]

[0048]

[0049] The trivalent chromium hard chrome electroplating solution of above-mentioned embodiment 1-12 is all formulated according to the following method:

[0050] First, dissolve the complexing agent, buffer, catalyst and conductive salt in 50% measured deionized water, heat to 90°C, react for 2.5 hours, and let it stand for 12 hours. Then, add trivalent chromium main salt and stir thoroughly for 2 hours. The electroplating solution contains nano-materials, then add it at this time, then add the remaining 50% of the measured deionized water, stir evenly, use the iridium-tantalum-coated titanium plate with low oxyge...

Embodiment 12

[0054] Embodiment 12 Electroplating object: base material No. 45 steel shaft-shaped parts (diameter 30 × length 200mm)

[0055] Mechanical polishing - chemical degreasing 5min - hanger, install shielding - anode electrolytic degreasing 1min - water washing - activation until bubbles - water washing - pure water washing - hard chrome plating (start directly to the specified current Density) - washing - pure water washing - unloading

[0056] Hard chrome plating conditions: 40°C, 30A / dm 2 , plating time 20min.

[0057] Results: The coatings of the 12 experimental groups were all peeled and cracked.

Embodiment 13

[0058] Embodiment 13 Electroplating object: base material No. 45 steel shaft-shaped parts (diameter 30 × length 200mm)

[0059] Mechanical polishing - chemical degreasing 5min - hanger, install shielding - anode electrolytic degreasing 1min - water washing - activation to bubbles - water washing - pure water washing - hard chrome plating (soft start, cathode remains static , solution without stirring) - washing - pure water washing - unloading

[0060] Hard chrome plating condition: 40℃, 60A / dm 2 , Plating time 25min.

[0061] Results: The coating thickness of each experimental group was 55-65um, the current efficiency exceeded 36%, the hardness reached 950HV, and the bonding force passed the 300°C thermal shock test without peeling, peeling or cracking.

[0062] The corrosion resistance of the coatings in the five groups of Examples 8-12 all reached the neutral salt spray test for more than 150 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com