Single-coil, single-suction cup, multi-channel parallel direct-acting, multi-component solenoid valve

A single-coil, multi-channel technology, applied in the direction of engine components, valve details, valve devices, etc., can solve the problems of large overall structure, heavy mass, and complex engine electrical system of the thrust device, so as to reduce the difficulty of assembly and testing process and light weight , The effect of simplifying the layout of the assembly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

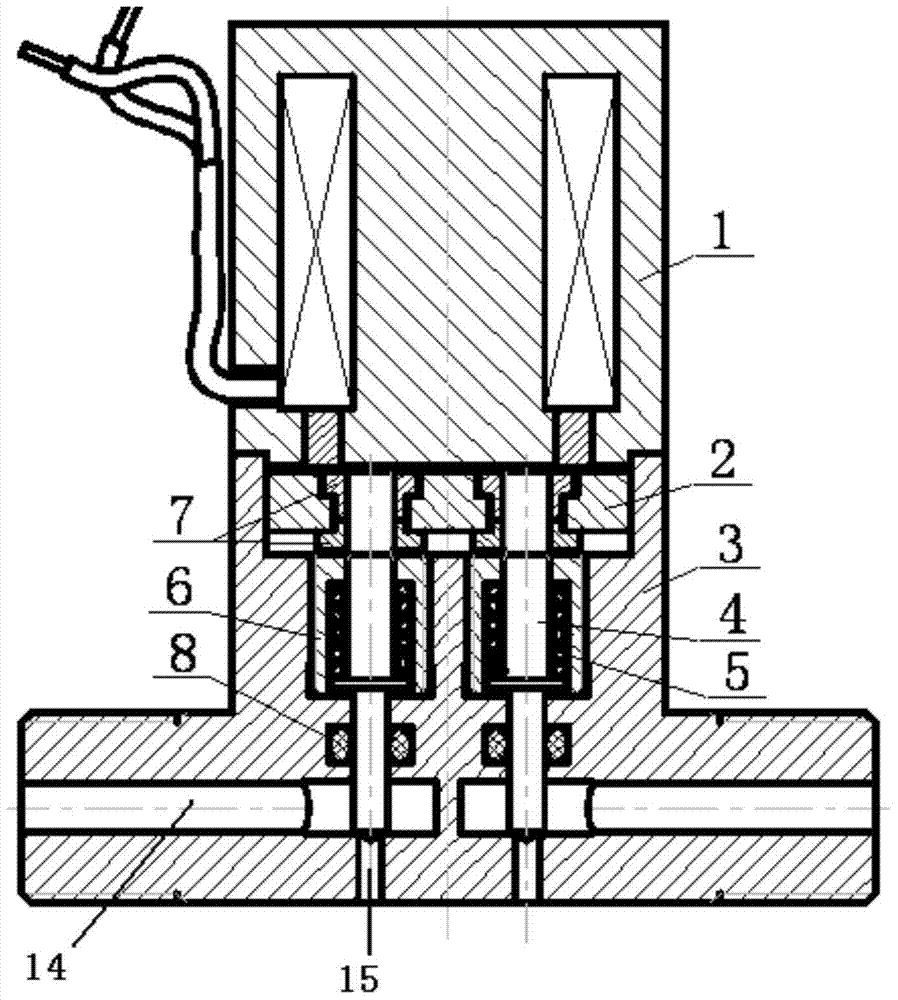

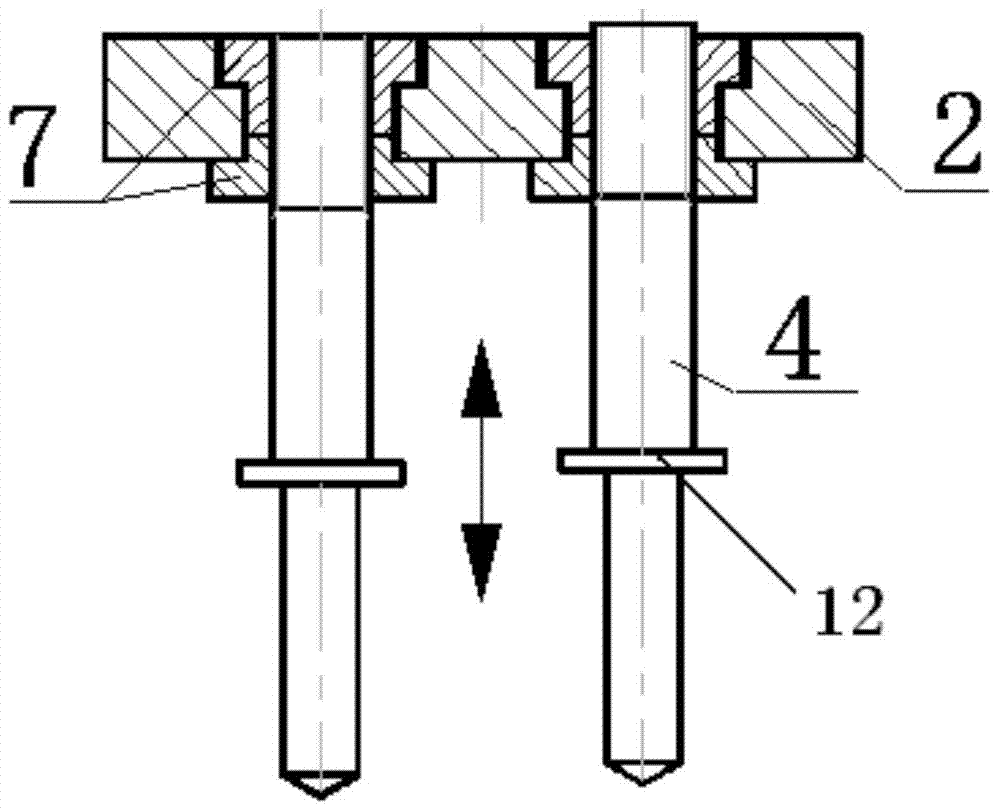

Embodiment 1

[0041] In order to meet the development needs of miniaturization, light weight, and fast response thrust devices of weapon systems such as mobile warheads and interceptors, a single-coil, single-chuck, multi-channel parallel direct-acting device with small structure, light weight and fast response is proposed. Type multi-component solenoid valve program, see figure 1 . The solenoid valve is mainly composed of an electromagnetic drive coil 1, a disc armature 2, a valve body 3, multiple valve stems 4, multiple return sealing springs 5, multiple spring sleeves 6, multiple sets of screw sleeves 7 and multiple O Shaped seal 8 is composed. When the electromagnetic drive coil 1 is not energized, the magnetic poles on the end face do not produce attractive force. Under the action of the force of the reset sealing spring 5 of each path, the valve stem 4 of each path is pressed against the valve seat, and the medium is sealed upstream of the valve port. When the electromagnetic drive co...

Embodiment 2

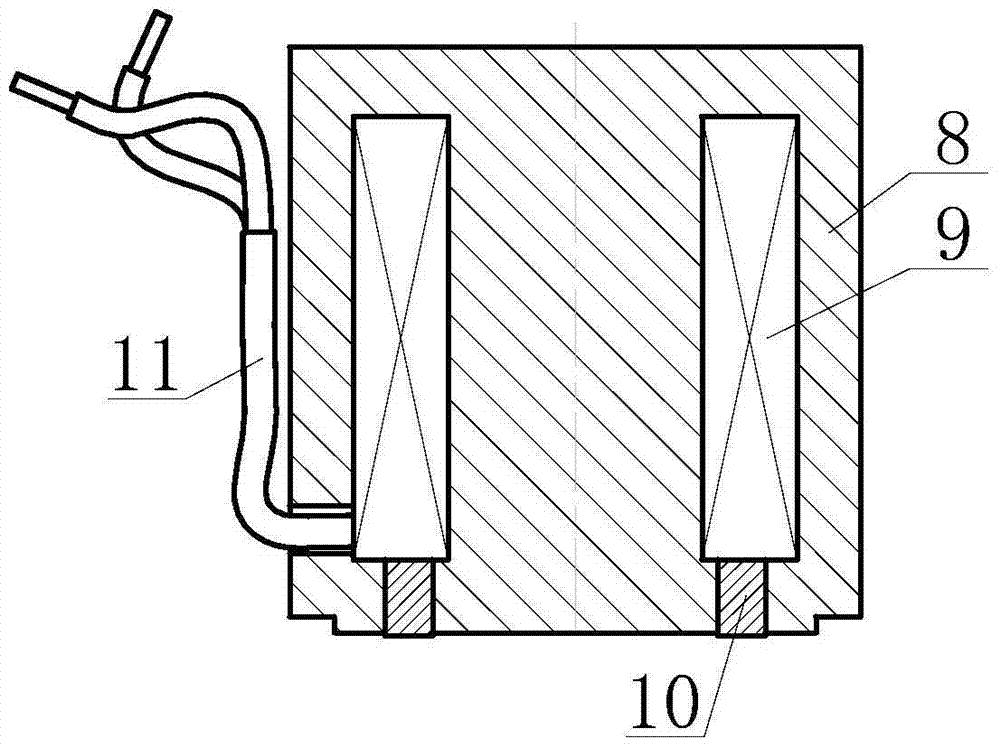

[0043] The single-coil, single-chuck, multi-channel parallel direct-acting multi-element solenoid valve is the same as in Example 1. For the electromagnetic drive coil of the present invention, see figure 2 , Mainly composed of a coil bobbin 8, an enameled wire 9, a release ring 10 and a wire 11. Its characteristic is that the end surface of the coil bobbin 8 is a magnetic pole. In order to speed up the response performance of the electromagnetic drive coil 1, the 350 turns of enameled wire 9 wound on the coil bobbin 8 of the present invention constitutes an electromagnetic drive coil 1 with a small number of turns and low inductance. A release ring 10 is placed in the middle of the end surface magnetic poles, which protrudes magnetically. The height of the extreme surface is 0.1mm, and the non-working air gap between the pull-in rear disc armature 2 and the end surface magnetic pole of the electromagnetic drive coil 1 is increased, so that the suction force during release will ...

Embodiment 3

[0045] A single-coil, single-chuck, multi-channel parallel direct-acting multi-component solenoid valve is the same as in Example 1-2. For the sealing structure of the multi-channel medium channel of the present invention, see figure 1 , Each medium channel is mainly composed of the valve body 3, the valve stem 4, the return sealing spring 5, the spring sleeve 6 and the O-shaped seal 8. The multi-channel flow channels and the sealing structure are arranged independently and symmetrically on the valve body 3. Among them, the O-shaped seal 8 is installed in the sealing groove of the valve body 3, the valve stem 4 is inserted into the center holes on both sides of the valve body 3, the reset sealing spring 5 is sleeved on the upper part of the valve stem 4, and is screwed into the valve body 3 through the spring sleeve 6. Compress the reset sealing spring 5, and use the valve stem 4 to press on the valve seat to ensure the sealing of the medium passage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com