Whole-process production workstation for IC chips or MEMS devices

A workstation, full-process technology, applied in the direction of comprehensive factory control, instrumentation, program control, etc., can solve the problem of high production cost of IC chips and MEMS devices, and reduce plant occupation and maintenance area, reduce costs, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

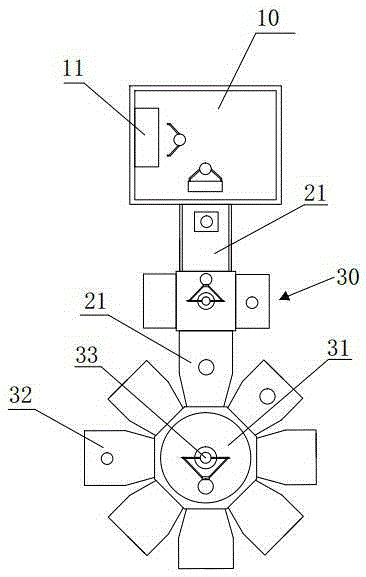

[0022] Example 1: see figure 1 , is a full-process production workstation that can be applied to the production, testing and analysis of IC chips and MEMS devices. The workstation is single-layer and linear, mainly including:

[0023] The dust-free man-machine exchange chamber 10 is used to manually pick and place workpieces and control the operation of workstations. The workpieces can be raw materials, semi-finished products or finished products of IC chips or MEMS devices.

[0024] The intelligent transmission chamber 20 is connected between the man-machine exchange chamber and the process flow chamber or between the process flow chambers, and is used for transporting workpieces. In this embodiment, the intelligent transmission chamber is a horizontal intelligent transmission chamber 21 .

[0025] The process chamber 30 is arranged on the transmission line of the intelligent transmission chamber 20, and is composed of a central transportation chamber 31 and a plurality of sa...

Embodiment 2

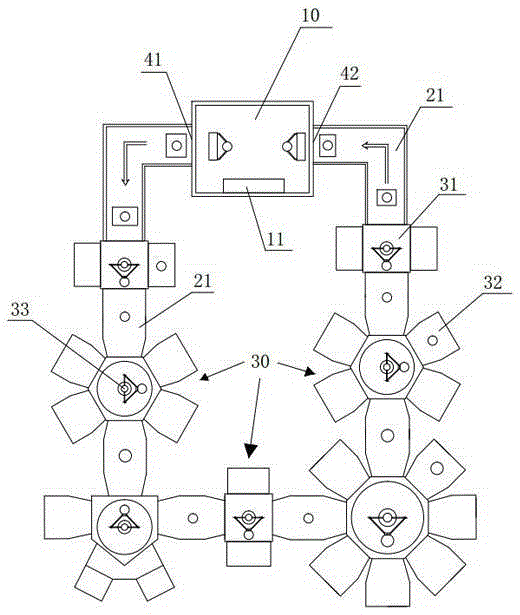

[0029] Example 2: see figure 2 , and the difference with Embodiment 1 is that: the whole process production workstation of this embodiment is single-layer and circular. In the whole workstation, there are two-star cavity, three-star cavity, four-star cavity and five-star cavity, which are connected by horizontal intelligent transmission cavity. The intelligent transmission chamber between the man-machine exchange chamber and the process chamber is transferred to the first process chamber through the conveyor belt, and the intelligent transmission chamber between the process chambers is completed by the manipulator or robot in the process chamber Pick and place the workpiece to realize the transmission. In the man-machine exchange chamber 10, raw materials and trays are manually put into the input window 41, and then enter the output window 42 of the man-machine exchange chamber through a series of processing in the process chamber 30 and transmission in the horizontal intell...

Embodiment 3

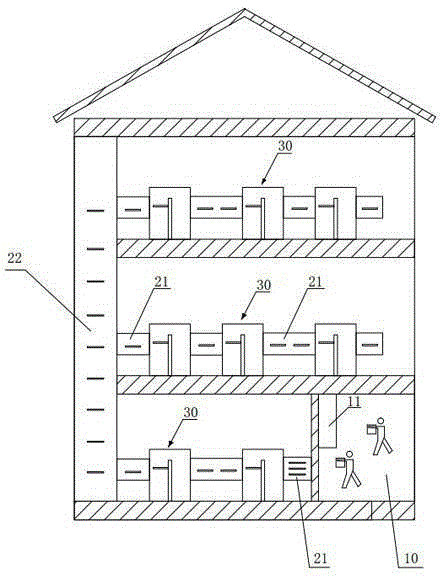

[0030] Embodiment 3: see image 3 , Different from Embodiments 1 and 2, the workstation described in this embodiment is designed as a multi-layer structure, specifically the upper and lower 3-layer workrooms. Among them, the human-machine exchange chamber 10 and the intelligent control mechanism 11 are arranged in the first-floor workshop, which is convenient for manual operation; the process flow chamber 30 is respectively arranged in the first, second, and third-floor workshops. The inner process flow chamber is designed as the linear structure in embodiment 1, of course, it can also be designed as the circular structure in embodiment 2. The workpiece transmission in the same layer is realized through the horizontal intelligent transmission chamber 21 , while the workpiece transmission between layers is realized through the upper and lower intelligent transmission chambers 22 .

[0031] see Figure 4 , is the upper and lower intelligent transmission mechanism in the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com