Preparation method of TFT array substrate, array substrate and display device

A technology for array substrates and pattern layers, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of large number of masks and increased costs, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

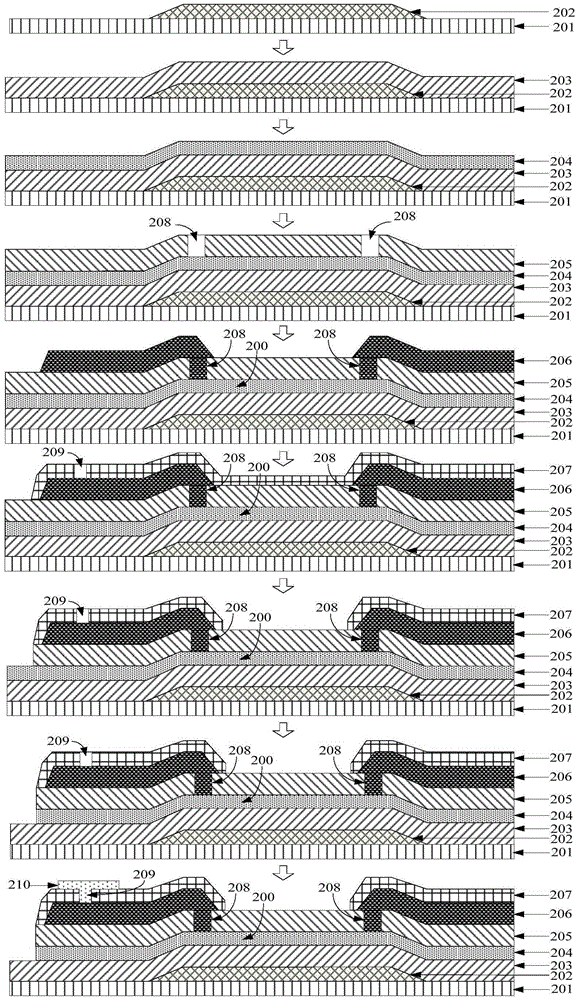

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

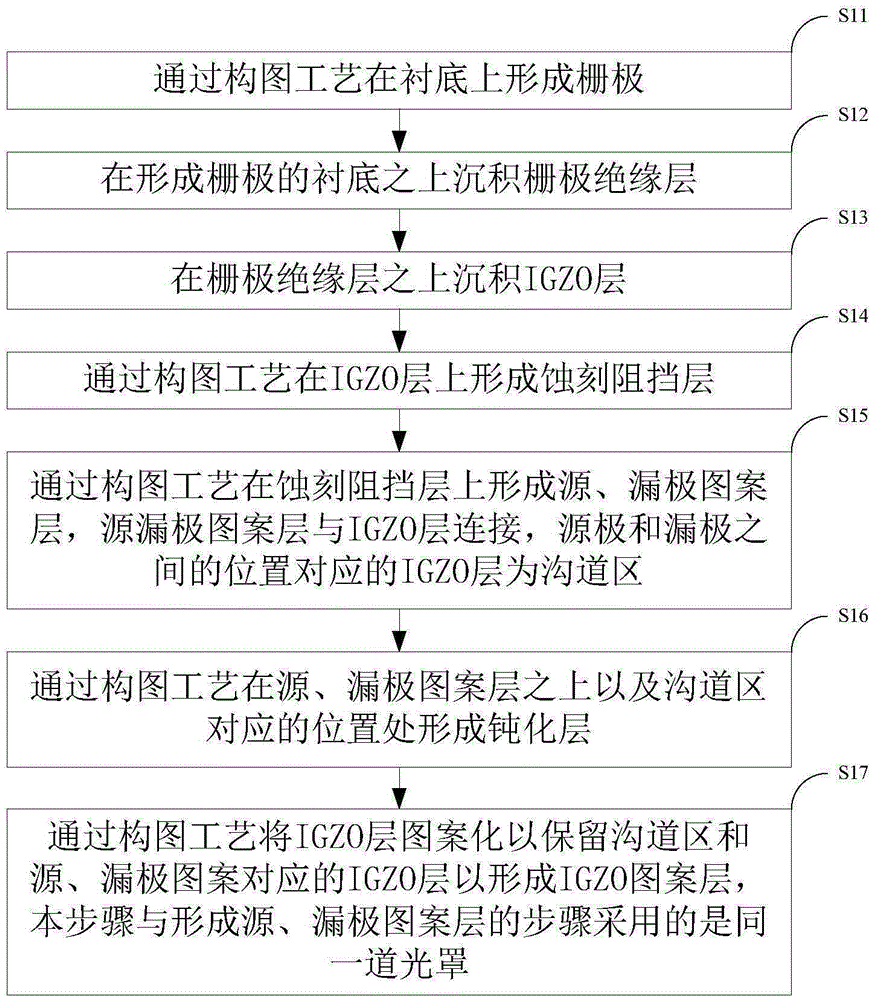

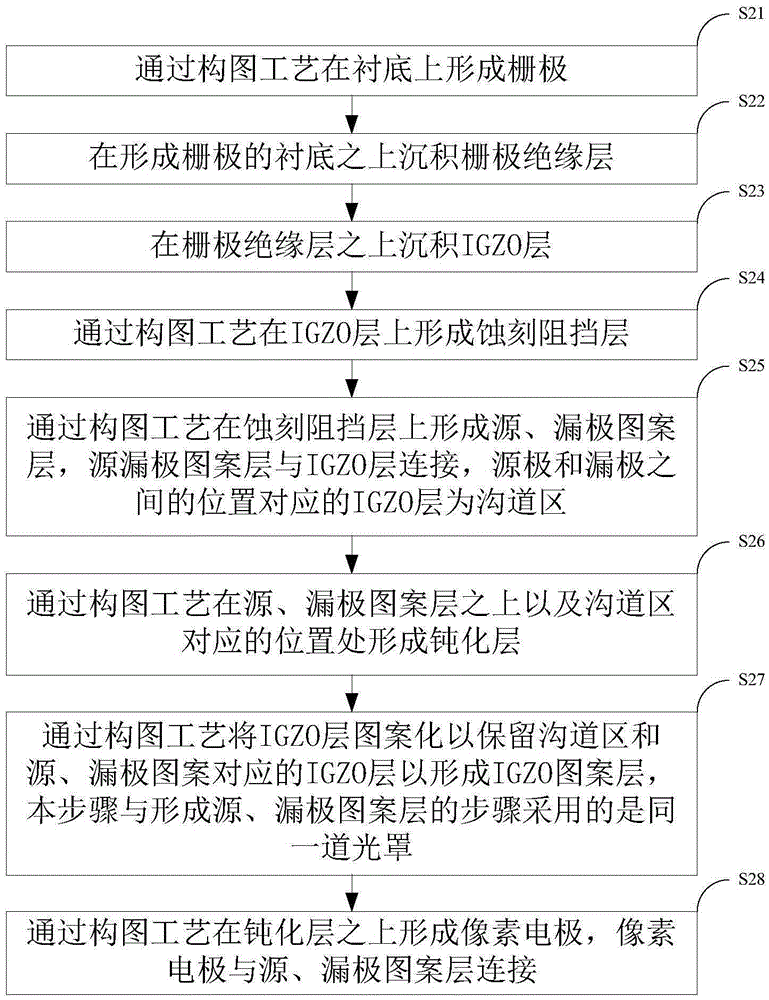

[0029] see figure 1 , figure 1 It is a schematic flow chart of the first embodiment of the manufacturing method of the TFT array substrate of the present invention.

[0030] S11, forming a gate on the substrate through a patterning process.

[0031] The gate is formed of metal, such as molybdenum, copper, aluminum and aluminum alloy, or a metal compound conductive layer formed by stacking aluminum layer, tungsten layer and chromium layer.

[0032] S12 , depositing a gate insulating layer on the substrate for forming the gate.

[0033] The gate insulating layer is formed by CVD or PECVD technology. The gate insulating layer can be one layer or two layers. One layer can be SiO 2 、SiN x Or AlO, the second layer generally uses SiN x .

[0034] S13, depositing an IGZO layer on the gate insulating layer.

[0035] The IGZO layer is used as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com