Bee feed containing defatted tenebrio molitor powder and preparing method thereof

A technology of Tenebrio molitor powder and a preparation method, which are applied in the field of feed and achieve the effects of wide material sources, improved disease resistance and enhanced physique

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

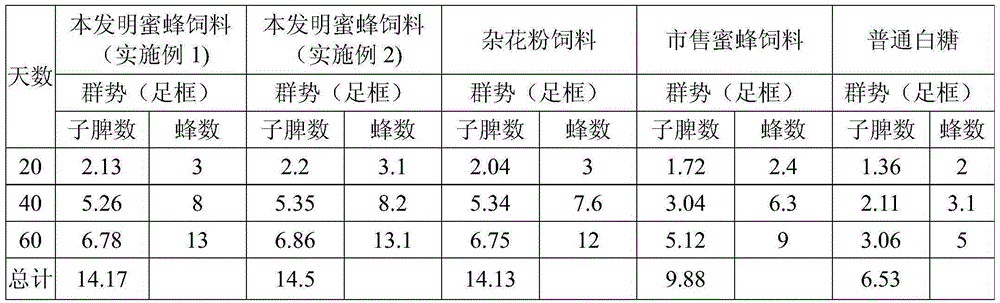

Examples

Embodiment 1

[0040] Example 1: Formulation

[0041] Dry powder 500g, water 125-175g, honey 100g, sugar 400g, empty honeycomb 1-1.5 pieces, the composition of the dry powder: 20% natural pollen, 35% defatted Tenebrio molitor powder, 6% freeze-dried mulberry powder, wheat germ 34.8%, brewer's yeast powder 4%, citric acid 0.2%,

[0042] Production Method:

[0043] 1. Preparation method of defatted Tenebrio molitor powder bee feed:

[0044] ⑴Defatted Tenebrio molitor powder, mulberry freeze-dried powder, malt powder. The production method is as described above.

[0045] (2) Deployment: first mix pollen with defatted Tenebrio molitor powder, freeze-dried mulberry powder, malt powder, brewer's yeast powder, and anti-fungal agent to make dry powder and put it into a clean basin. Then pour in an appropriate amount of water, stir evenly, and let the water fully absorb the feed powder.

[0046] (3) To soak the feed powder thoroughly, it needs to stand for 5 hours.

[0047] (4) Mix honey into t...

Embodiment 2

[0051] A kind of defatted Tenebrio molitor powder bee feed, formula is as follows:

[0052] Dry powder 500g, water 125-175g, honey 100g, sugar 400g, empty honeycomb 1-1.5 pieces, the composition of the dry powder: 0% natural pollen, 45% defatted Tenebrio molitor powder, 6% freeze-dried mulberry powder, wheat germ 44.8%, brewer's yeast powder 4%, sodium citrate 0.2%.

Embodiment 3

[0054] Dry powder 500g, water 125-175g, honey 100g, sugar 400g, empty honeycomb 1-1.5 pieces, the composition of the dry powder: 0% natural pollen, 45% defatted Tenebrio molitor powder, 5% freeze-dried mulberry powder, astragalus extract The product is brown yellow or off-white powder (astragaloside IV, astragalus polysaccharide) 1%, wheat germ 44.8%, brewer's yeast powder 4%, sodium citrate 0.2%.

[0055] The production method is the same as in Example 1, and the spleen filling method is adopted during feeding, and 1 to 1.5 empty honeycombs are required.

[0056] Note: The honeycomb is also called the honeycomb. The honeybee's nest is made of wax plates. Several plates hang from the upper part of the beehive to the bottom. The two sides of the honeycomb are neatly arranged with hexagonal cells, which are called the honeycomb. Worker bees store honey and pollen in the cells of the comb. They also use propolis to polish the cells in which the queen bee lays her eggs. An empty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com