A closed high temperature reaction kettle

A high-temperature reaction kettle and kettle body technology, which is applied in chemical/physical/physicochemical processes, chemical instruments and methods, preparation of test samples, etc., can solve problems such as large heat loss, low cooling efficiency, and limited heat transfer area , to achieve the effect of less heat loss, small cooling load and high thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

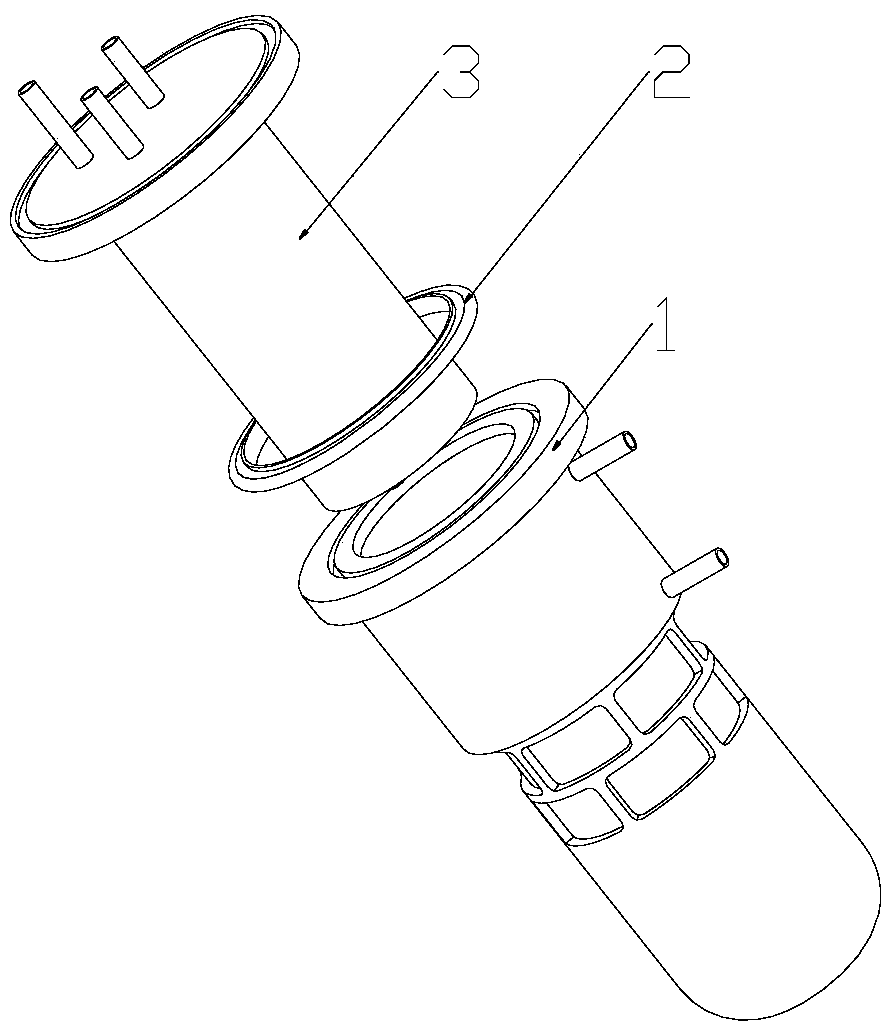

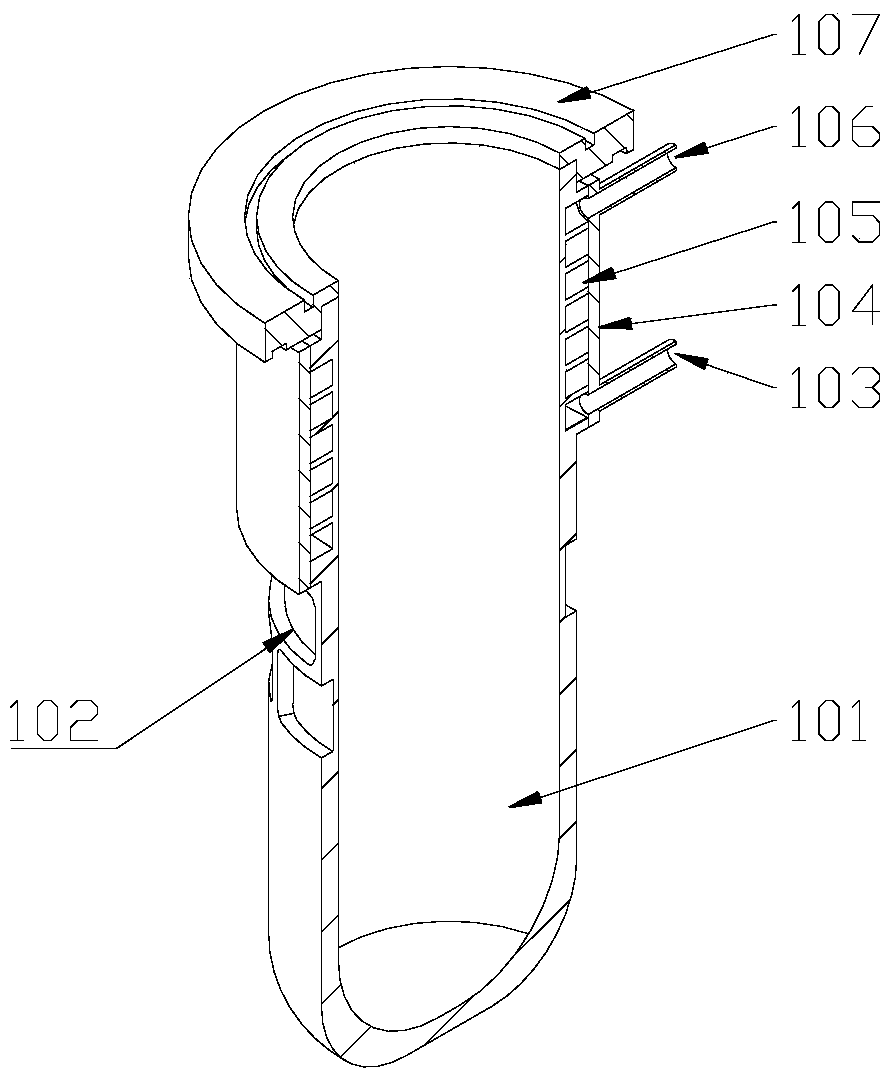

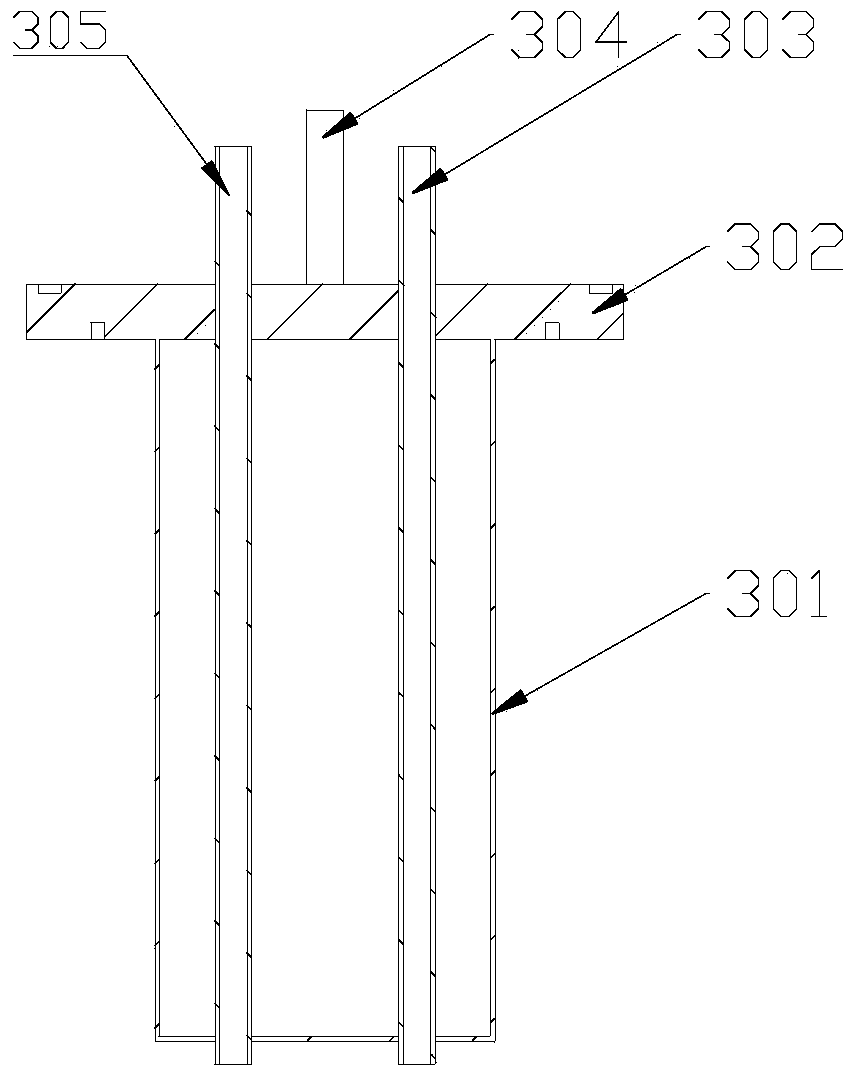

[0024] Put the metal Li into the bottom of the reactor body and press figure 1 The shown assembly relationship consolidates the kettle body and the kettle cover. Close the pressure relief pipe and the air inlet pipe, open the air outlet pipe and use a vacuum pump to vacuum the reactor. Open the water inlet and return pipes of the reactor, connect the cooling water, and put the bottom of the reactor into the crucible furnace. Slowly heat it to vaporize the petroleum ether on the surface of the metal Li and draw it out together with the air in the kettle. Heat to 700°C, open the air inlet pipe, and slowly introduce purified CO2. The temperature is raised to 900°C, the temperature is kept constant for 1 hour, the CO2 reacts with the metal Li completely, and the gas is pumped for 15 minutes. Turn off the electric furnace and cool to room temperature.

[0025] During the reaction process, the crucible furnace heats the reaction chamber part of the reaction kettle through heat radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com