Method for enhancing carbon fiber resin based composite material through organic modified nano-particles

A carbon fiber resin-based and nanoparticle technology is applied in the field of organically modified nanoparticle-reinforced carbon fiber resin-based composite materials to achieve the effects of improving thermal properties and mechanical properties, improving compressive strength and excellent impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

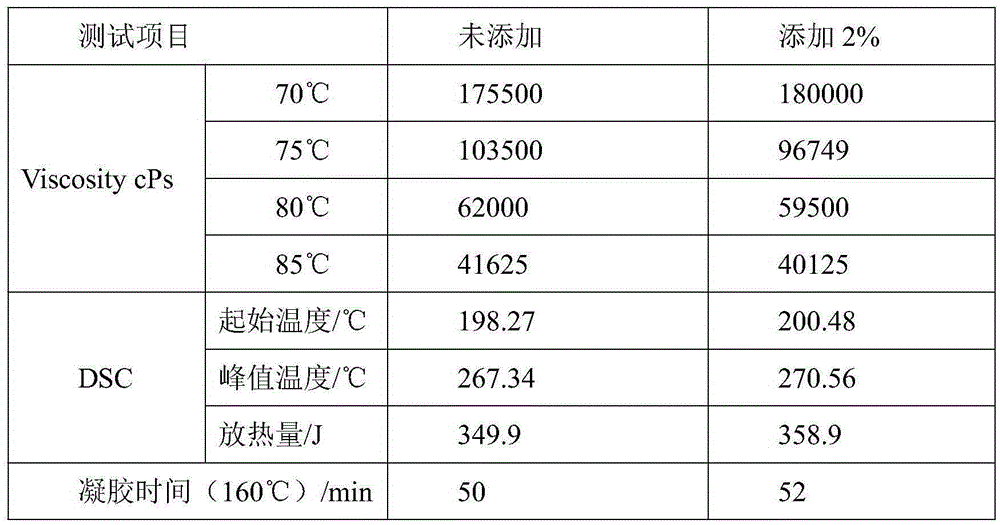

[0019] A method for organically modified nanoparticles to reinforce carbon fiber resin-based composite materials. Firstly, organic modifiers are used to treat nanoparticles to produce a small amount of amino functional groups on the surface, and then combine them with low-viscosity resin components in the reinforced resin system. Mechanical stirring and ultrasonic dispersion to uniformity to form a nano-enhancer masterbatch; add the nano-enhancer masterbatch to the resin system in a certain proportion, so that the mass percentage of nanoparticles in the entire resin system is 0.1% to 10%, and add nano-enhancer The resin system of the agent masterbatch is compounded with carbon fiber to prepare a carbon fiber resin matrix composite material.

[0020] The organic modifier adopts one or a mixture of cetyltrimethylammonium bromide, dihexadecyldimethylammonium bromide, 3-hexadecylammonium bromide, and silane coupling agent . The nanoparticles are one or a mixture of nano-montmoril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com