A heat partition for built -in steam stabilizers

A technology of thermal insulation baffle and voltage stabilizer, which is applied in the direction of reactor, reduction of greenhouse gas, nuclear power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

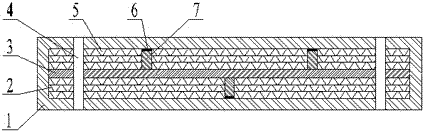

[0033] Such as figure 1 As shown, a thermal insulation partition suitable for a built-in steam pressurizer includes a housing 1, which is a hollow structure with a central cavity 5 disposed thereon, and a reflective foil is also disposed in the central cavity 5 slice 2.

[0034] In this embodiment, the above structure is used as the isolation part of the steam pressurizer and the reactor coolant, the outer casing 1 is used as a pressure-resistant part, and the central cavity 5 and the reflective foil 2 in the central cavity 5 are used as a heat insulation layer. . The shell 1 can be set to use metal plates such as stainless steel or titanium alloy. The material characteristics of the above shell 1 make it not only play the role of pressure-resistant parts, but also have good radiation resistance and high temperature resistance; the above reflective foil 2 is used The purpose of reducing convective heat transfer and radiation heat transfer is achieved through the reflection o...

Embodiment 2

[0037] The present embodiment is further limited on the basis of embodiment 1, as figure 1 with figure 2 As shown, in order to further strengthen the heat insulation effect of the present invention, the central cavity 5 is a sealed cavity, and the sealed cavity is a negative pressure cavity obtained by vacuuming. The above negative pressure chamber achieves the purpose by reducing convective heat transfer.

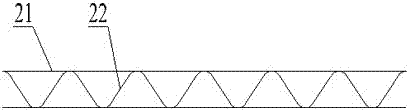

[0038] As an easy-to-install rebuttal foil structure, the reflective foil 2 includes a flat plate foil 21 and a corrugated plate foil 22, the flat plate foil 21 and the corrugated plate foil The surface of 22 is smooth surface.

[0039] As a kind of dense convective heat transfer can be suppressed through multiple layers, so that the reflective foil 2 has a better technical effect of reflecting heat radiation and reducing convective heat transfer, and at the same time facilitates the installation of flat plate foil 21 and corrugated plate foil 22, The structural form tha...

Embodiment 3

[0045] This embodiment is further limited on the basis of any one of the technical solutions provided by any one of the above embodiments, such as figure 1 As shown, in order to enable the present invention to better adapt to fluctuations between the internal reactor coolant of the built-in steam stabilized pressure and the reactor coolant of the external reactor coolant system, the shell 1 is also provided with a fluctuating channel 4 penetrating the shell 1 . The above fluctuating channel 4 promptly serves as a communication channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com