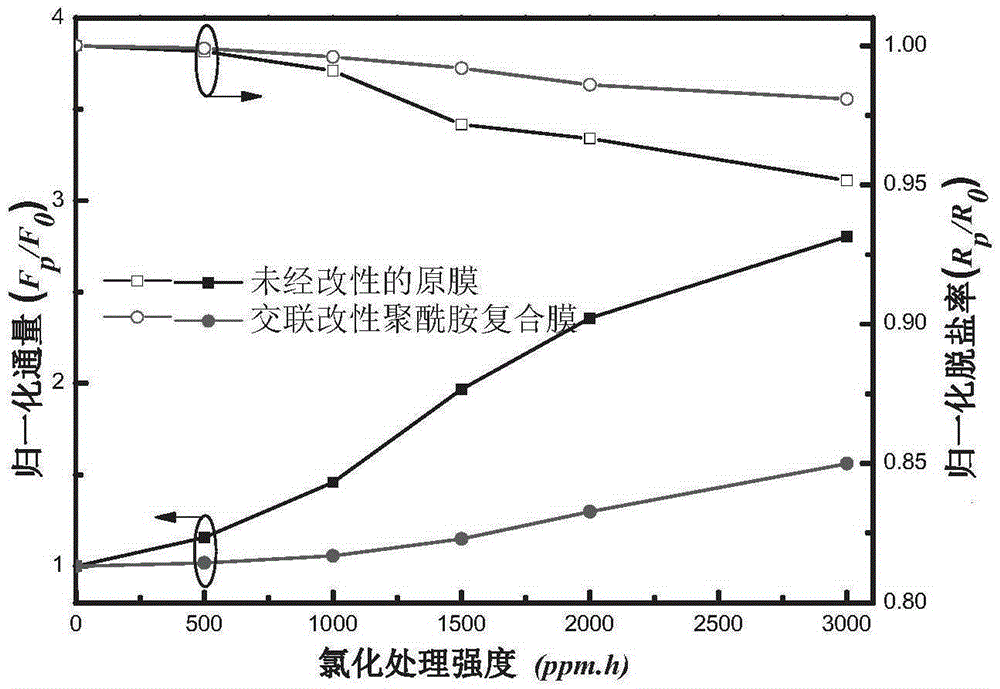

Crosslinking modified polyamide composite film and preparation method thereof

A cross-linking modification, polyamide technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of water flux decline, increase membrane permeability resistance, etc., to enhance separation performance and maintain compactness properties, and the effect of enhancing chlorine resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

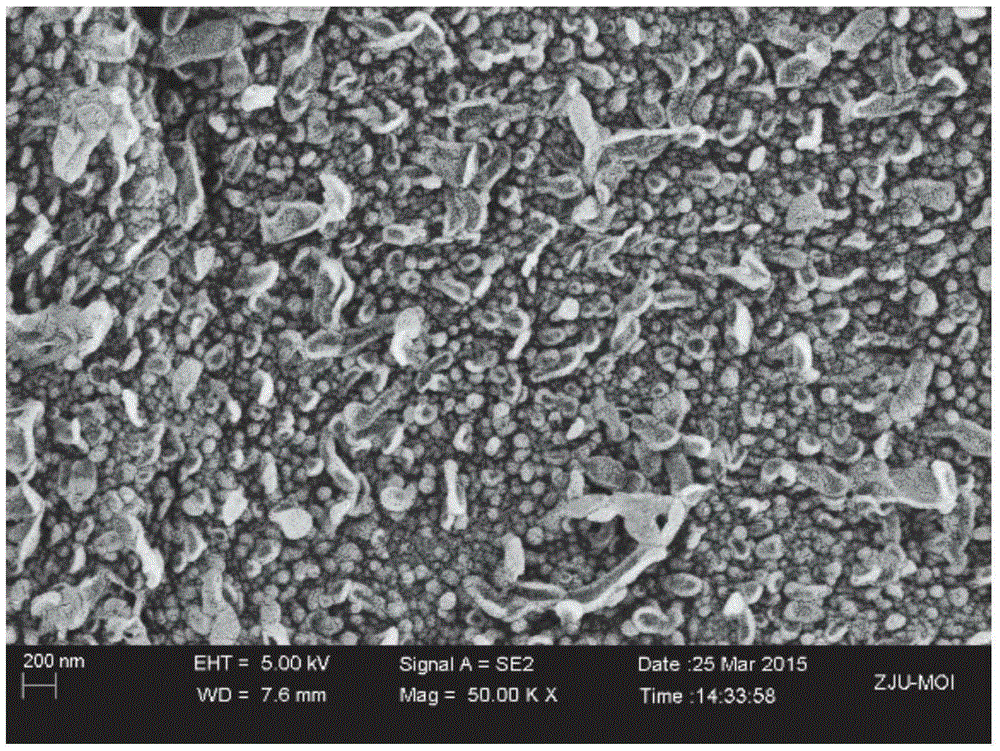

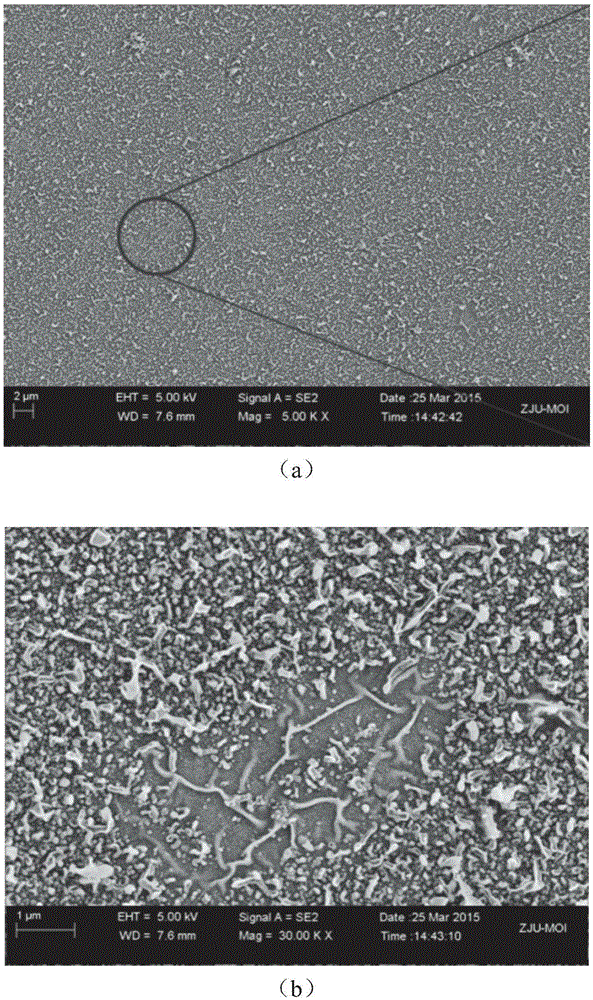

[0069] (1) Mixing a phosphoric acid solution with a volume percentage concentration of 80% and a formaldehyde solution with a volume percentage concentration of 40% at a volume ratio of 1:50 to obtain a reducing solution, and heating the reducing solution oil bath to a predetermined temperature and constant temperature;

[0070] (2) Immerse the polyamide composite membrane containing amino groups on the surface in a constant temperature reducing solution, react at a suitable stirring speed for 2 hours, take out the membrane and place it in deionized water to shake and wash to remove the remaining reducing solution in the membrane until it is cleaned There is no obvious formaldehyde smell in the liquid, and the polyamide composite film (N-MethylolPA, denoted as MH-PA) modified by N-methylolation is obtained;

[0071] (3) Use concentrated HCl to adjust the pH of the glutaraldehyde solution with a concentration of 2% by weight to 5, immerse the MH-PA in the above glutaraldehyde so...

Embodiment 4~5

[0074] (1) Mix a phosphoric acid solution with a concentration of 80% by volume and a formaldehyde solution with a concentration of 40% by volume at a volume ratio of 1:50 to obtain a reducing solution, and heat the reducing solution to an oil bath of 60° C. and keep the temperature constant;

[0075] (2) Immerse the polyamide composite membrane containing amino groups on the surface in a constant temperature reducing solution, react at a suitable stirring speed for 2 hours, take out the membrane and place it in deionized water to shake and wash to remove the remaining reducing solution in the membrane until it is cleaned There is no obvious formaldehyde smell in the liquid, and MH-PA is obtained;

[0076] (3) Use concentrated HCl to adjust the pH of the dialdehyde solution with a concentration of 2% by weight to 5, immerse MH-PA in the above dialdehyde solution, stir and react for 4 hours, take out the membrane and place it in deionized water for shaking and cleaning to remove...

Embodiment 6~8

[0079] (1) Mix an acetic acid solution with a volume percentage concentration of 80% and a formaldehyde solution with a volume percentage concentration of 40% at a volume ratio of 1:50 to obtain a reducing solution, and heat the reducing solution oil bath to a predetermined temperature and keep the temperature constant;

[0080] (2) Immerse the polyamide composite membrane containing amino groups on the surface in a constant temperature reducing solution, react at a suitable stirring speed for 2 hours, take out the membrane and place it in deionized water to shake and wash to remove the remaining reducing solution in the membrane until it is cleaned There is no obvious formaldehyde smell in the liquid, and MH-PA is obtained;

[0081] (3) Use concentrated HCl to adjust the pH of the glutaraldehyde solution with a concentration of 2% by weight to 5, immerse the MH-PA in the above glutaraldehyde solution, stir and react for 4 hours, take out the membrane and place it in deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com