Solid-phase extraction filler, solid-phase extraction column and preparation method and application of solid-phase extraction filler

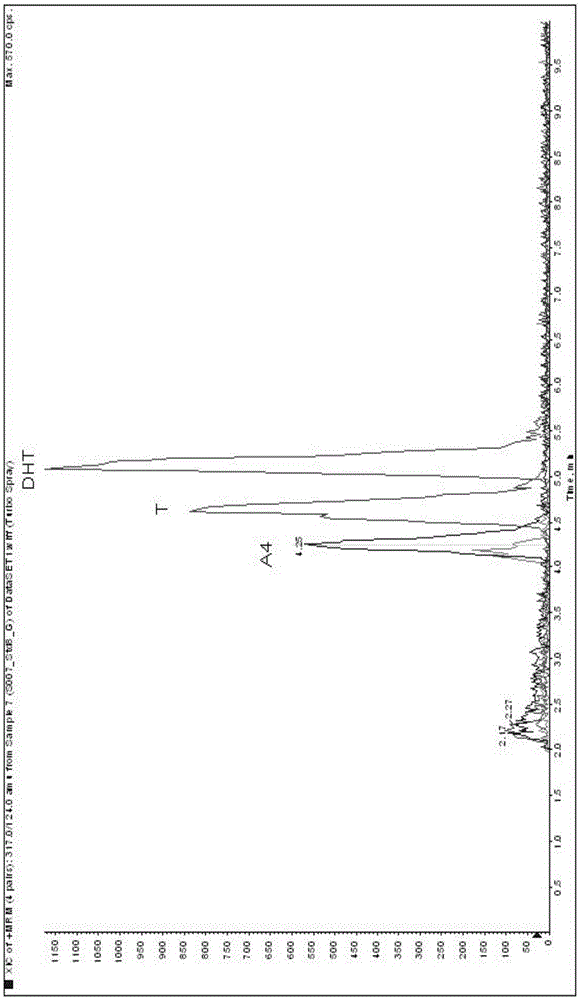

A solid-phase extraction column and extraction technology, which is applied in the field of instrument analysis, can solve the problems of low sample capacity, inability to complete rinsing and concentration in one step, and a single extraction functional group, achieving high reproducibility and high extraction recovery rate , high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

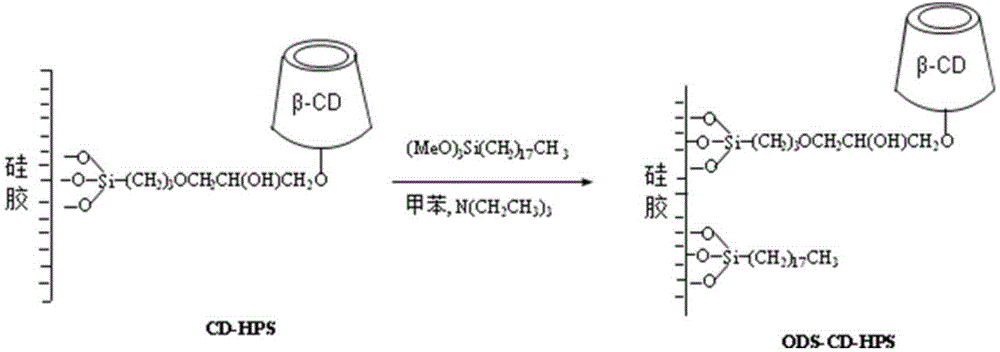

[0031] The preparation method of solid phase extraction filler ODS-CD-HPS comprises the following steps:

[0032] (1) Synthesis of material CD-HPS: Dissolve 22 grams of β-cyclodextrin after vacuum drying (0.1mmHg, 110°C, 14h) in 500 ml of anhydrous dimethylformamide, add 24 mg of sodium hydride Finally, stir the reaction solution at room temperature under the protection of nitrogen to form a transparent solution; then add 3.5 ml of 3-(2,3-epoxypropoxy)propyltrimethoxysilane to the reaction solution, After reacting for 5 hours, add 20 grams of activated silica gel after vacuum drying (particle diameter is 10~20 μm, pore diameter is ), reacted at 120°C for 24 hours; after the reaction mixture was cooled to room temperature, filtered it with a G4 sand core funnel, and the filter cake was washed with dimethylformamide, water, and methanol in turn; finally, the filter cake was placed in a Soxhlet extractor , using acetone as a solvent to extract for 12 hours to obtain bonded sili...

Embodiment 2

[0038] The preparation method of solid phase extraction filler ODS-CD-HPS comprises the following steps:

[0039] (1) Synthesis of material CD-HPS: Dissolve 25 g of β-cyclodextrin after vacuum drying (0.2 mmHg, 120 ° C, 12 h) in 600 ml of anhydrous dimethylformamide, add 26 mg of sodium hydride Finally, stir at room temperature under the protection of nitrogen until the reaction solution is transparent; then add 4.2 ml of 3-(2,3-epoxypropoxy)propyltrimethoxysilane to the reaction solution, and react at 70°C under the protection of nitrogen for 6 After 1 hour, add 22 grams of activated silica gel (particle diameter is 10~20 μm, pore diameter is ), reacted at 110°C for 26 hours; after the reaction mixture was cooled to room temperature, filtered it with a G4 sand core funnel, and the filter cake was washed with dimethylformamide, water, and methanol in sequence; finally, the filter cake was placed in a Soxhlet extractor , using acetone as a solvent to extract for 14 hours to o...

Embodiment 3

[0044] The manufacture of solid-phase extraction cartridges includes the following steps: take a 1 ml empty column, directly fill with 8-10 mg of ODS-CD-HPS filler to form a compact and uniform column bed, and seal both ends of the filler with a sieve plate, To prevent packing leakage, one end of the column is a sample or solvent injection port, and the other end of the column is a sample or solvent outflow port, and the sample or solvent is injected from one end of the column.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com