Preparation method of high-purity caffeine

A caffeine, high-purity technology, applied in separation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of affecting separation effect, limited separation capacity, complex extracts, etc., to improve preparation efficiency and high sample loading capacity. , the effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] a. Take 1 kg of dried tea leaves, add ethanol at a ratio of 1:5 to liquid, and heat to reflux for 30 minutes. The resulting solution was concentrated to dryness by rotary evaporator. Add 1L of water, ultrasonically disperse and dissolve, then filter to obtain the filtrate;

[0032] The obtained filtrate is loaded onto a HPD 300 macroporous resin (inner diameter 10 cm, column bed height 30 cm) chromatographic column for adsorption. And wash the chromatographic column with water as the eluting reagent until the eluate is colorless. The macroporous resin chromatographic column is eluted with ethanol as the elution solvent, and the eluate is concentrated to dryness with a rotary evaporator, redissolved with water, and freeze-dried to obtain a brown-yellow tea extract. Take 100 mg of the tea extract, dissolve it in 2 mL of water, dissolve it by ultrasonic, remove the precipitate by centrifugation, and use it as the first sample injection solution;

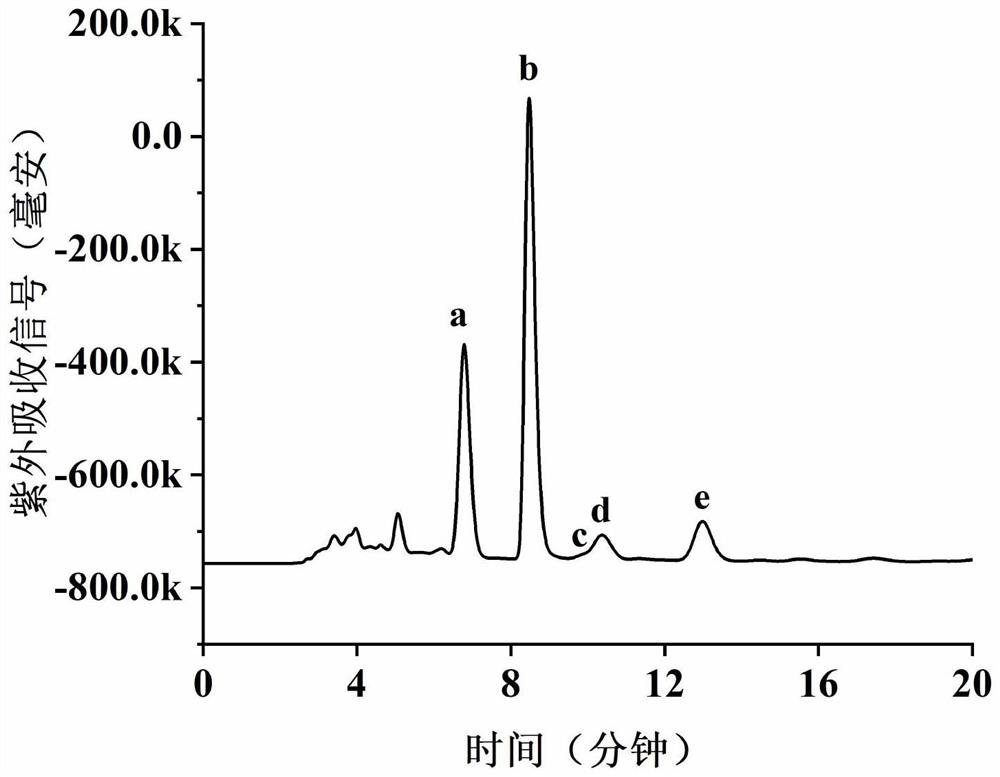

[0033] A reversed-phas...

Embodiment 2

[0040] a. Take 1 kg of dried tea leaves, add ethanol at a ratio of 1:2 to liquid, and heat to reflux for 30 minutes. The resulting solution was concentrated to dryness by rotary evaporator. Add 1L of water, ultrasonically disperse and dissolve, then filter to obtain the filtrate;

[0041] The obtained filtrate is loaded onto a HPD 300 macroporous resin (inner diameter 10 cm, column bed height 30 cm) chromatographic column for adsorption. And wash the chromatographic column with water as the eluting reagent until the eluate is colorless. The macroporous resin chromatographic column is eluted with ethanol as the elution solvent, and the eluate is concentrated to dryness with a rotary evaporator, redissolved with water, and freeze-dried to obtain a brown-yellow tea extract. Take 100 mg of the tea extract, dissolve it in 5 mL of water, dissolve it by ultrasonic, remove the precipitate by centrifugation, and use it as the first sample injection solution;

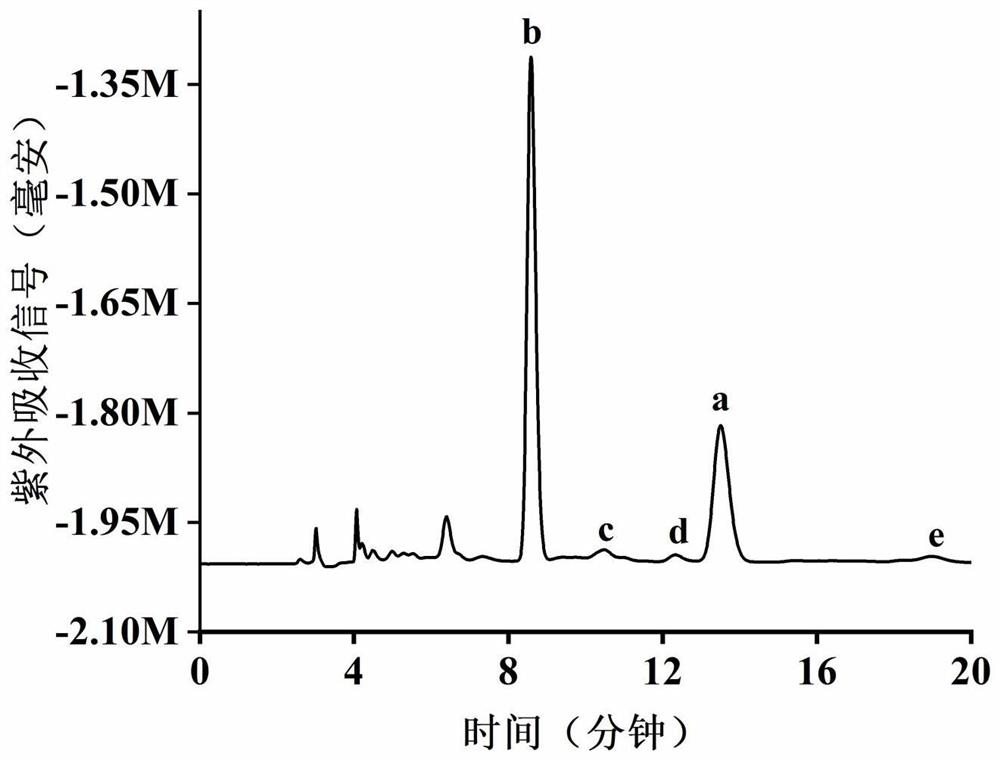

[0042] b. A reversed-p...

Embodiment 3

[0046] a. Take 1 kg of dried tea leaves, add ethanol at a ratio of 1:3 to liquid, and heat to reflux for 30 minutes. The resulting solution was concentrated to dryness by rotary evaporator. Add 1L of water, ultrasonically disperse and dissolve, then filter to obtain the filtrate;

[0047] The obtained filtrate is loaded onto a HPD 300 macroporous resin (inner diameter 10 cm, column bed height 30 cm) chromatographic column for adsorption. And wash the chromatographic column with water as the eluting reagent until the eluate is colorless. The macroporous resin chromatographic column is eluted with ethanol as the elution solvent, and the eluate is concentrated to dryness with a rotary evaporator, redissolved with water, and freeze-dried to obtain a brown-yellow tea extract. Take 100mg of the tea extract, dissolve it in 1.42mL of water, dissolve it by ultrasonic, remove the precipitate by centrifugation, and use it as the first sample injection solution;

[0048] b. A reversed-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com