Flexible capacitor type micromachining ultrasonic transducer (CMUT) and preparation method thereof

A technology of capacitive micromachining and ultrasonic transducers, which is applied in the direction of fluid using vibration, can solve the problems of reduced coupling efficiency, inability to detect close contact with the object surface, and inability to make flexible arrays, so as to reduce ultrasonic loss and facilitate large-scale The effect of widening application and overcoming bandwidth limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

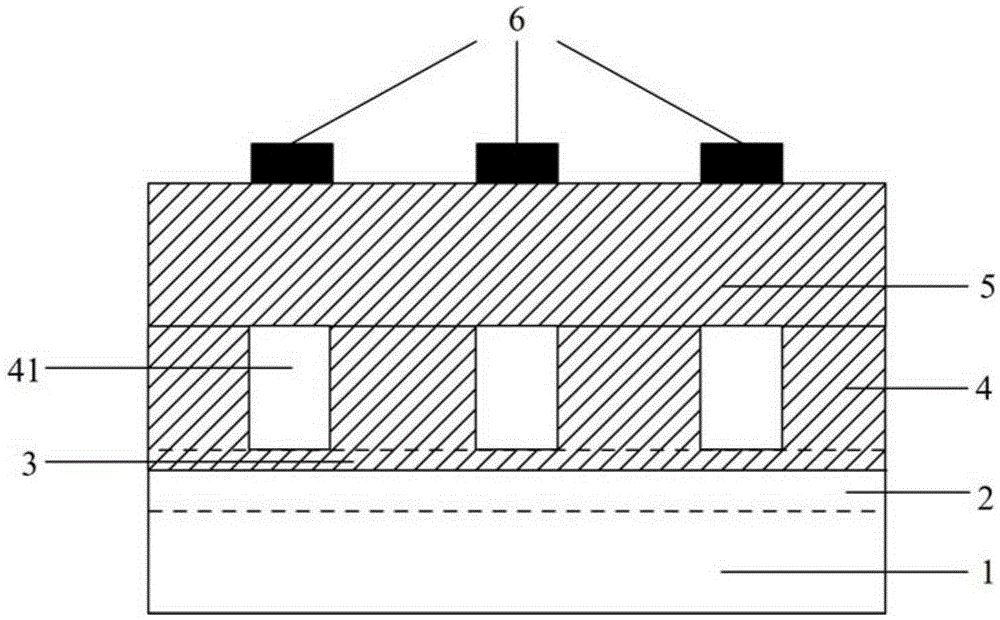

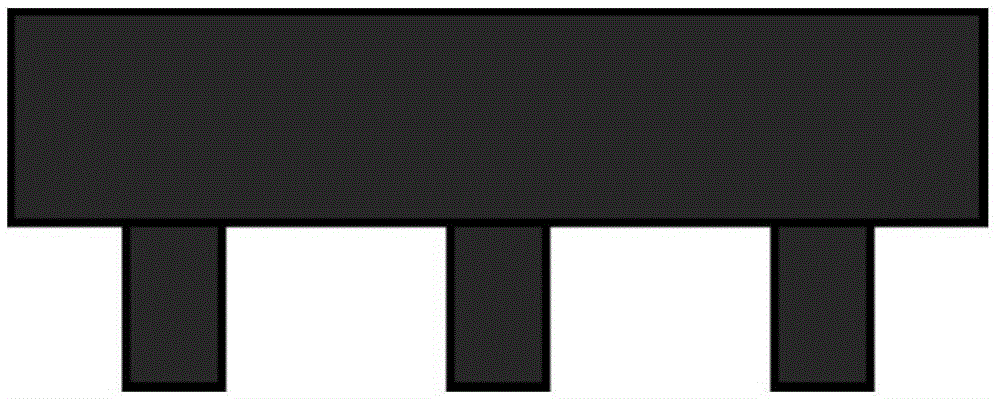

[0044] The flexible capacitive micromachining ultrasonic transducer of this embodiment includes a flexible PCB substrate 1, a lower electrode 2, an etching sacrificial layer 3, an organic polymer support layer 4, an organic polymer vibration film 5, and an upper electrode arranged in sequence. 6. The organic polymer supporting layer 4 is provided with a groove 41, and the groove 41 and the organic polymer vibrating film 5 form a cavity of an ultrasonic transducer.

[0045] The groove is a cylindrical groove with a depth of 2.0-4.0 μm and a bottom diameter of 20-200 μm.

[0046] The organic polymer vibrating film has a thickness of 0.5-2.5 μm and is made of rubber or polyvinyl chloride plastic.

[0047] The upper electrode is aluminum film or silver film, and the lower electrode is copper film.

[0048] When the flexible capacitive micromachining ultrasonic transducer is applied, a DC voltage is applied between the upper and lower electrodes, the strong electrostatic field pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com