Elastic barrier environmental friendly composite film

An elastic film and elastic technology, which is applied in the field of preparation of environmentally friendly composite films, can solve the problems of lack of elasticity and flexibility, difficulty in functionalization of degradable material films, and restrictions on the application of polylactic acid films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

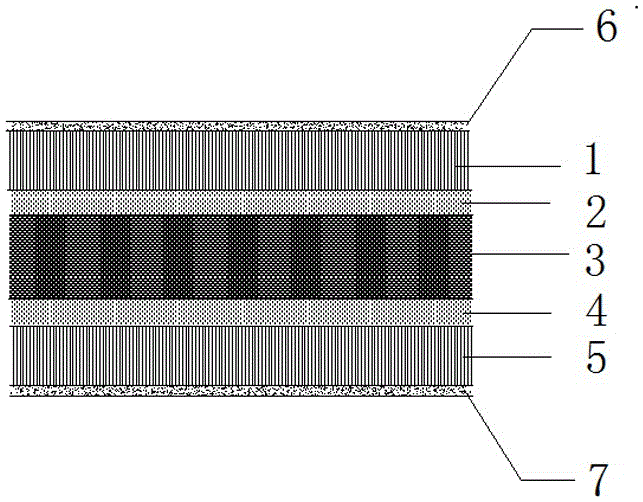

[0037] refer to figure 1 , an elastic barrier environment-friendly composite film, composed of multiple layers, including a bottom layer of starch elastic film 1, a middle layer of polylactic acid strength elastic film 3, and an outer layer of starch elastic film 5. Its features also include: an inorganic fiber coating 2 is provided between the bottom starch elastic film and the middle polylactic acid strength elastic film, an inorganic fiber coating 4 is provided between the middle polylactic acid strength elastic film and the outer starch elastic film, and the bottom starch The elastic membrane 1 and the outer starch elastic membrane 5 are spray-coated with superhydrophobic coatings 6 and 7 .

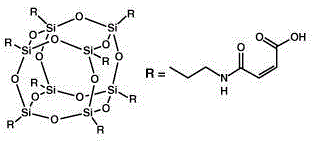

[0038]The bottom starch elastic film 1 and the outer starch elastic film 5 are mainly made of thermoplastic starch, thermoplastic polyurethane elastomer, starch grafted glycidyl methacrylate, and POSS grafted maleic anhydride. Oxygen agent and waterproof agent are extruded into film....

Embodiment 2

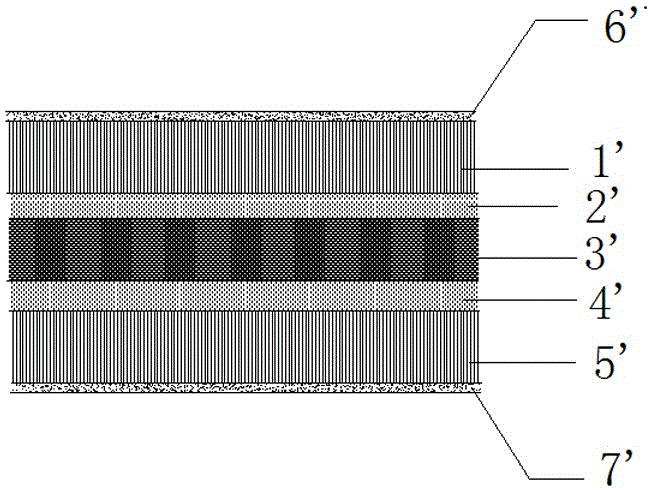

[0051] refer to figure 2 , an elastic barrier environment-friendly composite film, composed of multiple layers, including the bottom starch elastic film 1', the middle layer polylactic acid strength elastic film 3', and the outer starch elastic film 5'. Its features also include: an inorganic fiber coating 2' between the bottom starch elastic film and the middle polylactic acid strength elastic film, an inorganic fiber coating 4' between the middle polylactic acid strength elastic film and the outer starch elastic film, The bottom starch elastic film 1' and the outer starch elastic film 5' are sprayed with superhydrophobic coatings 6' and 7'.

[0052] The bottom starch elastic film 1' and the outer starch elastic film 5' are mainly made of thermoplastic starch, EVA, starch grafted glycidyl methacrylate, POSS grafted maleic anhydride, and a small amount of additives including antioxidant Agents and waterproofing agents are extruded into films. The mass fraction of thermoplas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com