Multiple-synergism type lockage removal agent

A technology of synergistic and unblocking agent, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of narrow adaptability, low blockage removal success rate, unsatisfactory blockage removal effect, etc. Wide, high success rate of blocking removal, improve the effect of blocking removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a multivariate synergistic block-removing agent, and its component mass ratio is composed of: 80-120 parts of water (tap water), 5-10 parts of cleaning and dissolving agent, 15-20 parts of corrosion agent, ammonium bifluoride 0.5-1 part, 0.4-0.6 part of Ninar, 2.5-3 parts of dodecyltrimethylammonium chloride, 0.1-0.3 part of ammonium persulfate, 2.5-3 parts of SA-3 corrosion inhibitor, HY215 for acidification 3-5 parts of iron ion stabilizer.

[0039] For example, the multi-element synergistic plug-removing agent has the following composition mass ratio: 120 parts of tap water; 5 parts of cleaning solvent; 15 parts of corrosion agent; 0.5 parts of ammonium bifluoride; 0.4 parts of Ninar; 2.5 parts of alkyltrimethylammonium chloride; 0.1 part of ammonium persulfate; 2.5 parts of SA-3 corrosion inhibitor; 3 parts of iron ion stabilizer for HY215 acidification. When in use, the multi-component synergistic plug-removing agent is transported to the ...

Embodiment 2

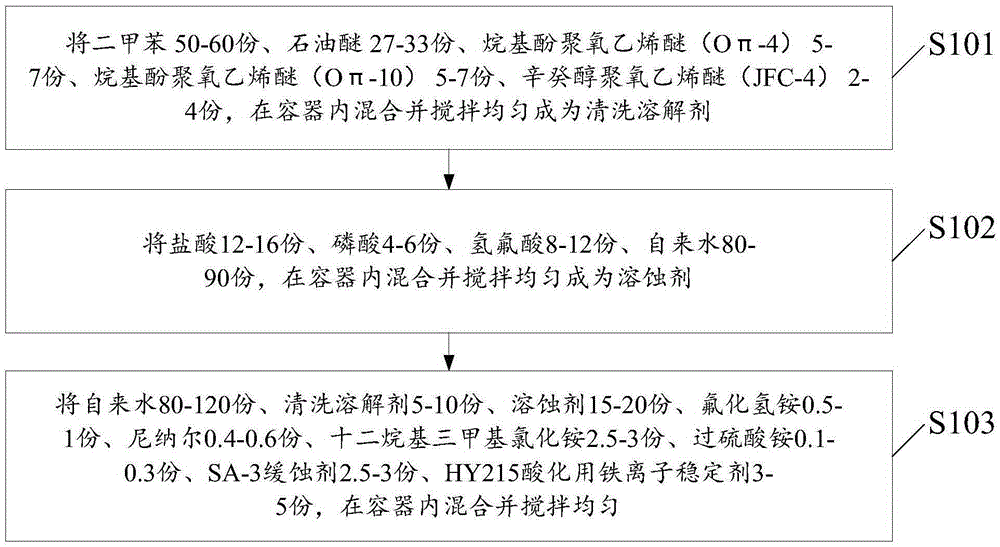

[0061] Based on the same inventive concept, this embodiment provides a method for preparing a multi-element synergistic plug-removing agent, such as figure 1 shown, including:

[0062] Step S101: 50-60 parts of xylene, 27-33 parts of petroleum ether, 5-7 parts of alkylphenol polyoxyethylene ether (Oπ-4), 5-7 parts of alkylphenol polyoxyethylene ether (Oπ-10) Parts, 2-4 parts of octadecyl alcohol polyoxyethylene ether (JFC-4), mix and stir in the container to become a cleaning solvent.

[0063] Step S102: Mix 12-16 parts of hydrochloric acid, 4-6 parts of phosphoric acid, 8-12 parts of hydrofluoric acid, and 80-90 parts of tap water in a container and stir evenly to form a corrosion agent.

[0064] Step S103: mix 80-120 parts of tap water, 5-10 parts of cleaning solvent, 15-20 parts of corrosion agent, 0.5-1 part of ammonium bifluoride, 0.4-0.6 part of Ninar, dodecyltrimethylammonium chloride 2.5-3 parts, 0.1-0.3 parts of ammonium persulfate, 2.5-3 parts of SA-3 corrosion inh...

Embodiment approach

[0070] The first one can be 120 parts by mass of tap water, 5 parts of cleaning solvent, 15 parts of corrosion agent, 0.5 part of ammonium bifluoride, 0.4 part of Ninar, 2.5 parts of dodecyltrimethylammonium chloride, persulfuric acid 10 tons of the multi-component synergistic plug-removing agent were prepared at the ratio of 0.1 parts of ammonium, 2.5 parts of SA-3 corrosion inhibitor, and 3 parts of iron ion stabilizer for HY215 acidification. When in use, it is transported to the construction site and injected into the target layer by a cement truck. According to indoor tests, the dissolution rate of organic plugs is 81%, the dissolution rate of inorganic plugs is 91%, the degradation rate of polymer plugs is 72%, and the recovery rate of core permeability is 86%.

[0071] The second one can be 80 parts of tap water, 10 parts of cleaning solvent, 20 parts of corrosion agent, 1 part of ammonium bifluoride, 0.6 parts of Ninar, 3 parts of dodecyltrimethylammonium chloride, 3 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com