Sparse-decomposition-based hybrid fault feature extraction method of gear wheel and bearing

A fault feature and extraction method technology, which is applied in mechanical bearing testing, machine gear/transmission mechanism testing, mechanical component testing, etc., can solve problems such as input classification and recognition algorithm fault feature signal extraction, single damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

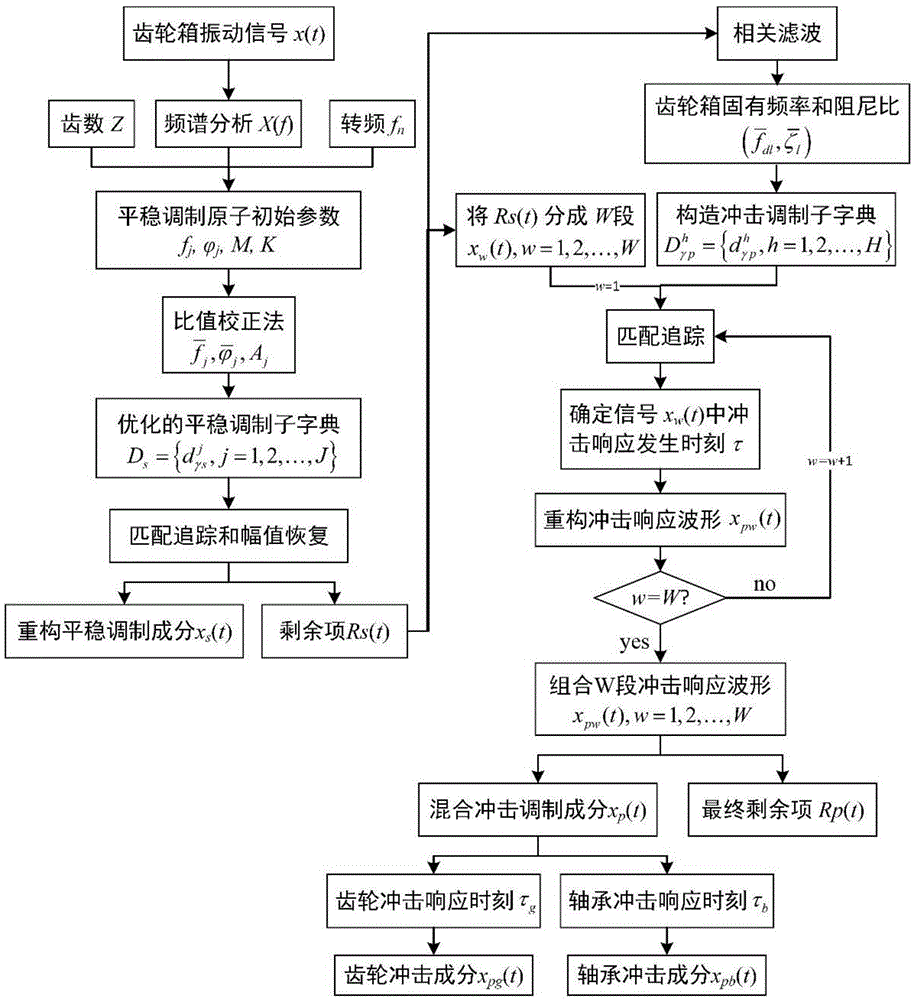

[0079] like figure 1 , this embodiment discloses a sparse decomposition-based feature extraction method for mixed gear and bearing faults, which can be used to diagnose mixed faults consisting of distributed gear faults and local gear and bearing faults in a gearbox. The specific implementation includes steps in the following order:

[0080] S1. Collect vibration acceleration signals including gear and bearing faults.

[0081] S2. Construct a stationary modulation dictionary, and optimize the atomic parameters in the dictionary atoms by using the ratio correction method, and extract the stationary modulation components in the signal by using the matching pursuit algorithm.

[0082] S3. Identify the multi-order natural frequencies and damping ratios of the gearbox including gears and bearings from the remaining signals by applying a correlation filtering method.

[0083] S4. Construct the shock modulation dictionary, segment the remaining signal, and use the matching pursuit ...

Embodiment 2

[0126] This embodiment specifically illustrates the feature extraction method for gear and bearing hybrid faults based on sparse decomposition disclosed in the present invention through a simulation test of mixed local faults of automotive transmission gears and bearings:

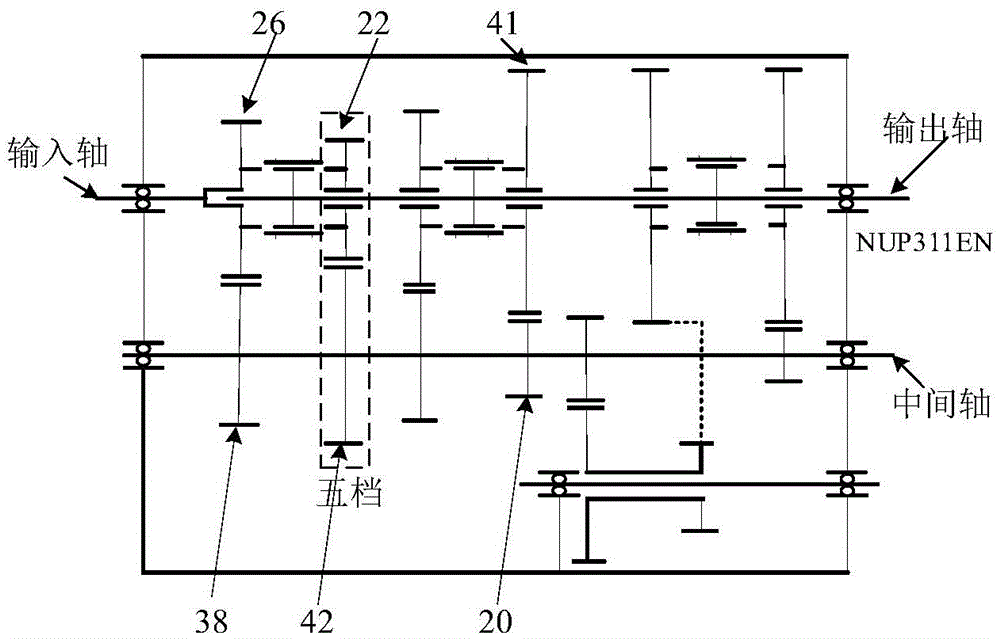

[0127] The tested gearbox is a three-shaft five-speed automotive manual transmission, and its structure is as follows: figure 2 shown. The mixed partial fault is composed of the inner ring fault of the rolling bearing at the output shaft end (model: NUP311EN, fault size: 0.2mm wide, 1mm deep) combined with broken teeth of the fifth-speed output gear. The experimental equipment is shown in Figure 3. Set the input shaft speed to 1000rpm, the operating parameters of the gearbox are listed in Table 1, and the structural parameters of the rolling bearing model NUP311EN are listed in Table 2.

[0128] Table 1 Experimental test gearbox operating parameters (unit: Hz)

[0129]

[0130]

[0131] Table 2 NUP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com