a plastic label

A plastic and label technology, applied in the label field, can solve the problems of hygroscopic formula foaming, difficult to degrade, and difficult industrial application, etc., and achieve the best moisture-proof and water-resistant performance, high strength, and good bottle washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

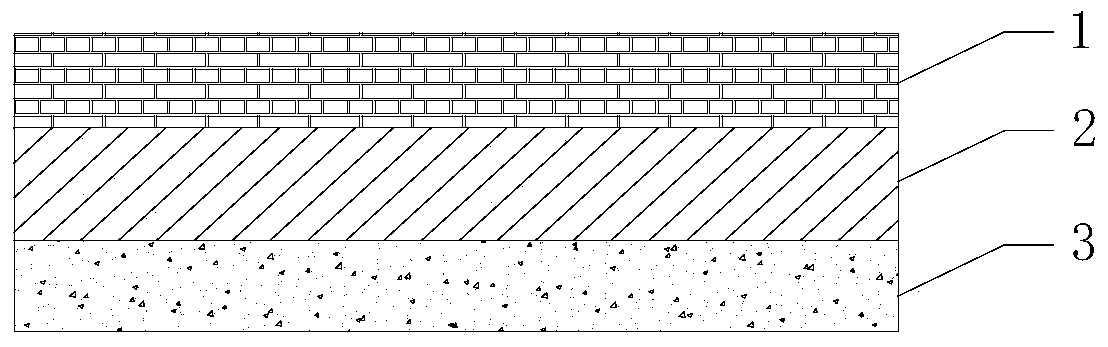

[0032] like figure 1 As shown, a plastic label includes: a printing layer 1, a plastic substrate layer 2 and a hygroscopic layer 3, and the printing layer 1, the plastic substrate layer 2 and the hygroscopic layer 3 are stacked and arranged sequentially from top to bottom.

[0033] Wherein, the printing layer 1 can be an ink layer or a drawing layer, and the printing layer can be monochromatic or colored, and it mainly serves as decoration and identification, such as printing serial numbers, barcodes, trademarks, decorative graphics, etc.

[0034] The thickness of the plastic substrate layer 2 is between 20-100 μm. A laser structure formed by laser molding of an anti-counterfeit laser grating is arranged on the plastic substrate layer 2 . In this embodiment, it is preferable that the plastic substrate layer is a heat-shrinkable material with a shrinkage coefficient of 1-80%. In this way, when washing the bottle, only the label part needs to be placed in lye solution at 50-90°...

Embodiment 2

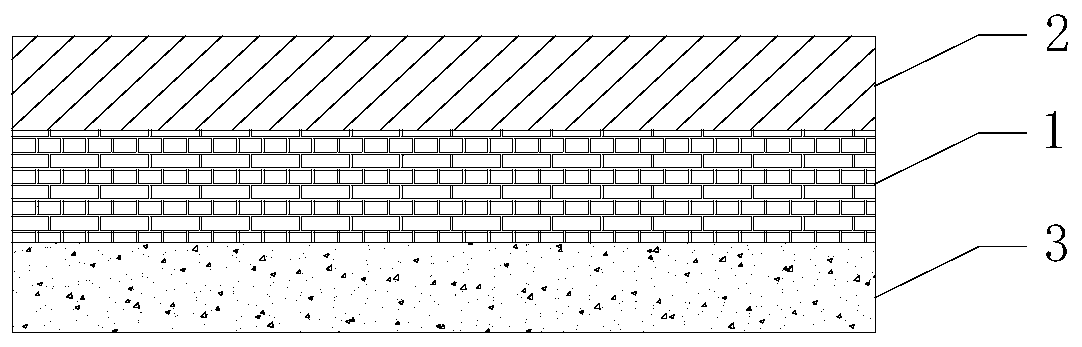

[0038] like figure 2 As shown, the structure of the plastic label provided by this embodiment is basically the same as that of Embodiment 1, the difference is that;

[0039] 1. The printing layer 1 is arranged on the lower surface of the plastic substrate layer 2 .

[0040] 2. There is no laser structure on the plastic substrate layer 2 .

Embodiment 3

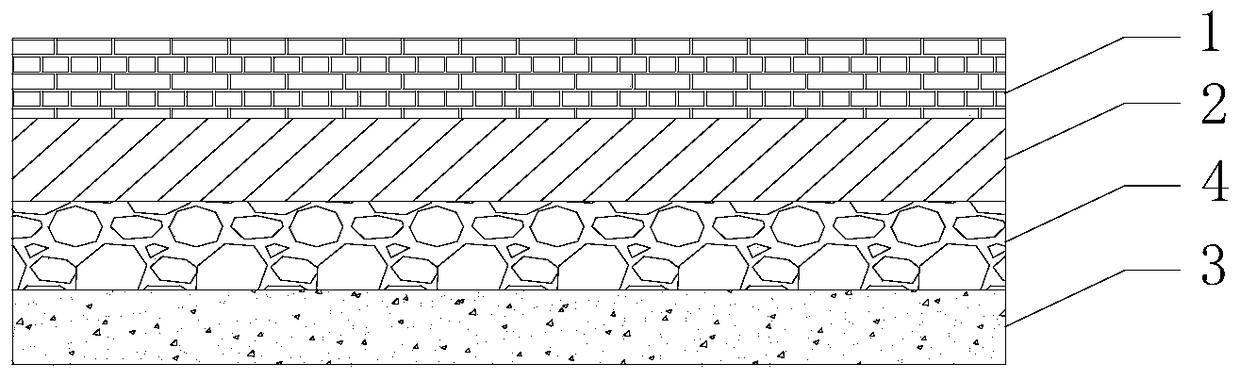

[0042] like image 3 As shown, the structure of the plastic label provided by this embodiment is basically the same as that of Embodiment 1, the difference is that a bottle-washing functional layer 4 is provided between the plastic substrate layer 2 and the hygroscopic layer 3 .

[0043] Wherein, the bottle washing functional layer 4 is prepared from the following raw materials by weight: 5% acrylic resin with a softening point lower than 20°C, 5% ammonium sulfate, 10% pigment, and 80% mixture of water and ethanol. In the actual bottle washing, the ammonium sulfate in the bottle washing functional layer and the sodium hydroxide in the cleaning solution have a double decomposition reaction, releasing gas to generate a push force, and peel off the plastic label and the container wall to which it is attached, so as to achieve the bottle washing effect. When the bottle washing functional layer 4 is provided, the plastic substrate layer 2 is made of non-shrinkable plastic film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com