Production method and intelligent control system for floating hydroponic green vegetables

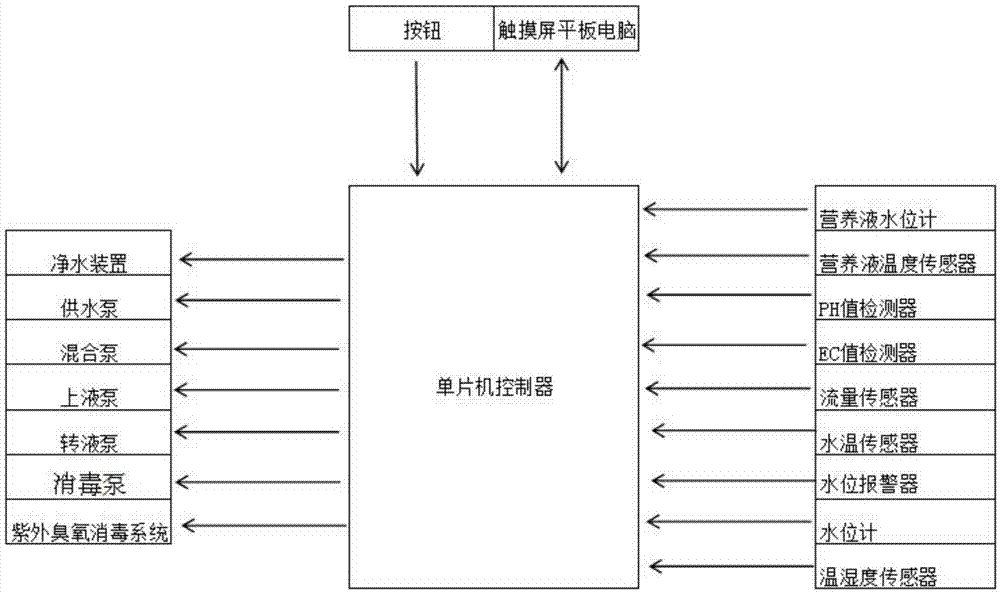

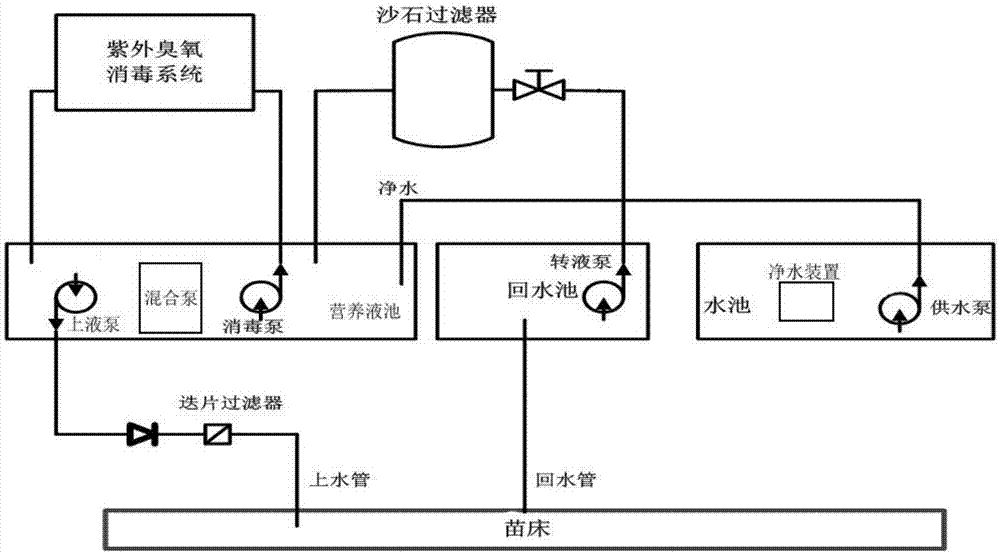

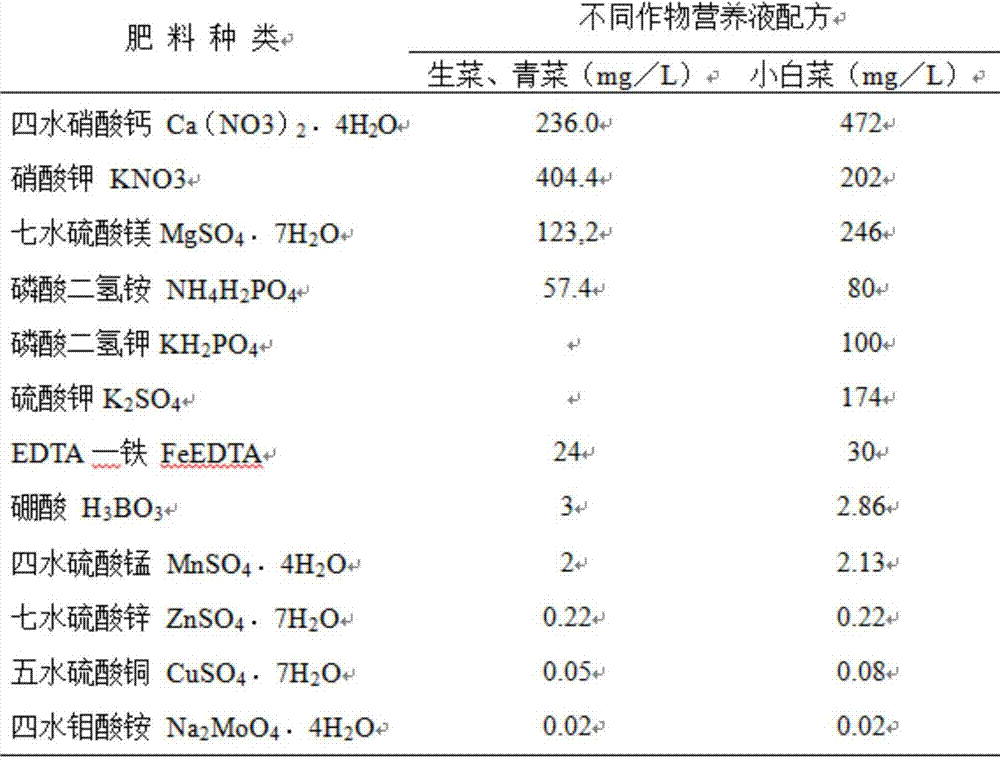

An intelligent control system, a technology for green leafy vegetables, applied in electrical program control, comprehensive factory control, botanical equipment and methods, etc., can solve problems such as drowning, pollution, biological pollution, etc. Easy to use and highly intelligent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A production method for floating hydroponic green leafy vegetables;

[0012] Step 1, making the matrix, uniformly mixing the high-temperature sterilized peat and perlite at a ratio of 3:1 by stirring with a machine; the pH value of the matrix after making is 5.5 to 6.5. During the process of the machine automatically stirring the matrix, the operator needs to grasp the appropriate water content of the matrix.

[0013] Step 2, sowing, putting the prepared matrix into a hole tray, then punching, sowing, covering with soil, and watering. Due to the mechanical agitation, one operator can sow 400 trays per hour in 128-hole trays. The size of the 128-hole tray is 55cm*27.5cm; the number of holes is 16*8=128 holes.

[0014] Step 3, germination, after sowing in the 128-hole hole tray, the lettuce and celery are subjected to a germination treatment for 3 to 4 days at an ambient temperature of 22°C. Pakchoi and green vegetables are subjected to a germination treatment for 2 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com