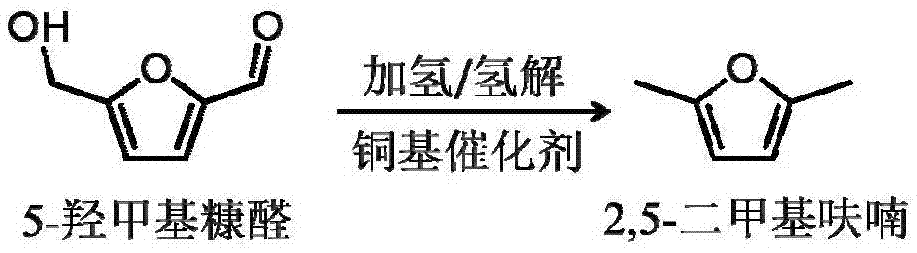

Catalyst used for preparing 2,5-methyl furan and preparation method thereof

A technology of dimethylfuran and copper-based catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve problems such as high production costs, achieve easy operation and reduce production costs , The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

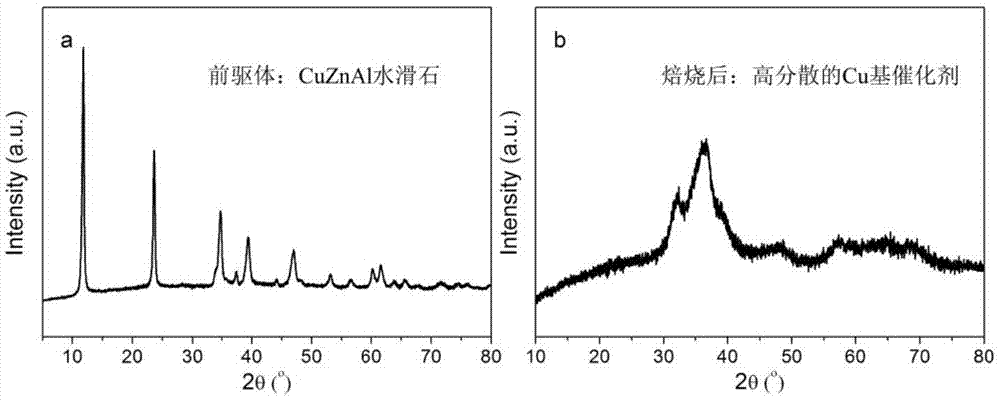

[0040] CuZnAl catalyst was prepared with hydrotalcite as precursor to catalyze the preparation of 2,5-dimethylfuran from 5-hydroxymethylfurfural.

[0041] Preparation of CuZnAl catalyst: configure Cu(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 2 9H 2 O mixed solution, in which the molar ratio Cu:Zn:Al=1:1:1, configure Na 2 CO 3 A mixed solution of NaOH and NaOH is co-precipitated under water bath conditions, the pH is maintained at 9-10, aged at 65°C for 150min, filtered, washed, and dried to obtain a hydrotalcite precursor, such as figure 2 as shown in a. Then the obtained hydrotalcite precursor is calcined at 350° C. for 4 h, and the intermediate product obtained is a highly dispersed Cu-based catalyst prepared from hydrotalcite as the precursor, such as figure 2 as shown in b. Then reduce the intermediate product in a hydrogen atmosphere, the flow rate of hydrogen is 140ml / min, the heating rate from room temperature to the reduction reaction temperature o...

Embodiment 2

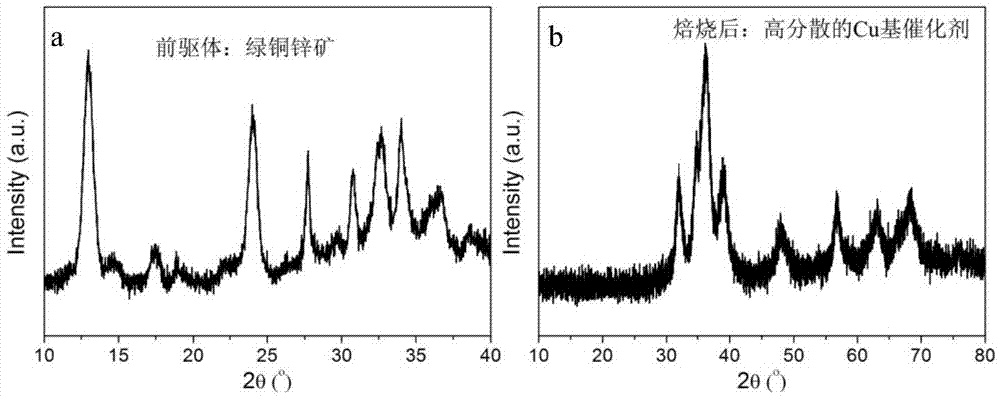

[0045]CuZn catalyst was prepared from green copper zinc ore as precursor to catalyze the synthesis of 2,5-dimethylfuran from 5-hydroxymethylfurfural.

[0046] Preparation of CuZn catalyst: weigh a certain amount of Cu(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 O was dissolved in deionized water, in which the molar ratio Cu:Zn=1:1, and a certain amount of Na was weighed 2 CO 3 Dissolve in deionized water, carry out co-precipitation under water bath conditions, maintain the pH at 6-7, age at 65°C for 150 minutes, filter, wash, and dry to obtain the green copper zinc ore precursor, such as image 3 as shown in a. Then the obtained precursor was calcined at 350°C for 4h, and the obtained intermediate product was a highly dispersed Cu-based catalyst prepared by the precursor, such as image 3 as shown in b. Then reduce the intermediate product in a hydrogen atmosphere, the flow rate of hydrogen is 140ml / min, the heating rate from room temperature to the reduction reaction tempera...

Embodiment 3

[0050] CuZn catalyst was prepared by using the mixed phase of copper-zinc malachite and green copper-zincite as precursor to catalyze the synthesis of 2,5-dimethylfuran from 5-hydroxymethylfurfural.

[0051] Preparation of CuZn catalyst: weigh a certain amount of Cu(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 O was dissolved in deionized water, in which the molar ratio Cu:Zn=2:1, weighed a certain amount of Na 2 CO 3 Dissolve in deionized water, carry out co-precipitation under water bath conditions, maintain pH at 6-7, age at 65°C for 150 minutes, filter, wash, and dry to obtain a mixed-phase precursor of copper-zinc malachite and green copper-zinc ore, such as Figure 4 as shown in a. Then the obtained precursor is calcined at 350 ° C for 4 h, and the obtained intermediate product is a highly dispersed Cu-based catalyst prepared by the mixed phase as the precursor, such as Figure 4 as shown in b. Then reduce the intermediate product in a hydrogen atmosphere, the flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com