Method for preparation of bamboo-shaped carbon nanotube by ultrasonic atomization

A technology of carbon nanotubes and ultrasonic atomization, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high price and high production cost, and achieve simple reaction device and low processing capacity adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Add 577mgFeCl 3 , 354.4 mg of terephthalic acid was dissolved in 50 mL of redistilled N,N-dimethylformamide, and it was fully dissolved by ultrasonication at room temperature for 5 minutes to obtain a uniformly mixed solution.

[0026] 2. Add the homogeneous solution obtained in 1 into the atomizer, and ultrasonically atomize to produce droplets, which are passed through N 2 Gas (0.6L / min) was loaded into the tube furnace which had been preheated to 700°C for reaction.

[0027] 3. The obtained solid particles are collected by ultrasonic elution with a mixed solution of ethanol and water, washed with a solvent, and then dried in vacuum to obtain bamboo-shaped carbon nanotubes.

Embodiment 2

[0029] 1. Add 577mgFeCl 3 , 354.4 mg of terephthalic acid was dissolved in 50 mL of redistilled N,N-dimethylformamide, and it was fully dissolved by ultrasonication at room temperature for 5 minutes to obtain a uniformly mixed solution.

[0030] 2. Add the homogeneous solution obtained in 1 into the atomizer, and ultrasonically atomize to produce droplets, which are passed through N 2 Gas (0.6L / min) was loaded into a tube furnace that had been preheated to 800°C for reaction.

[0031] 3. The obtained solid particles are collected by ultrasonic elution with a mixed solution of ethanol and water, washed with a solvent, and then dried in vacuum to obtain bamboo-shaped carbon nanotubes.

[0032] Embodiment 3~13 and embodiment 1~2 difference see the table below:

[0033]

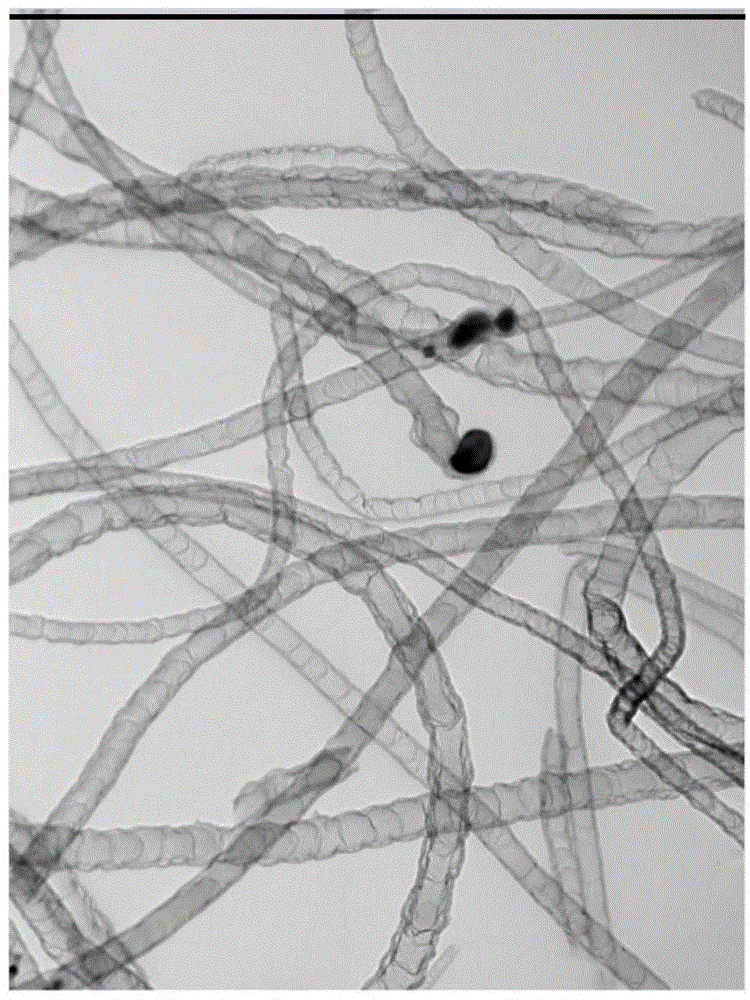

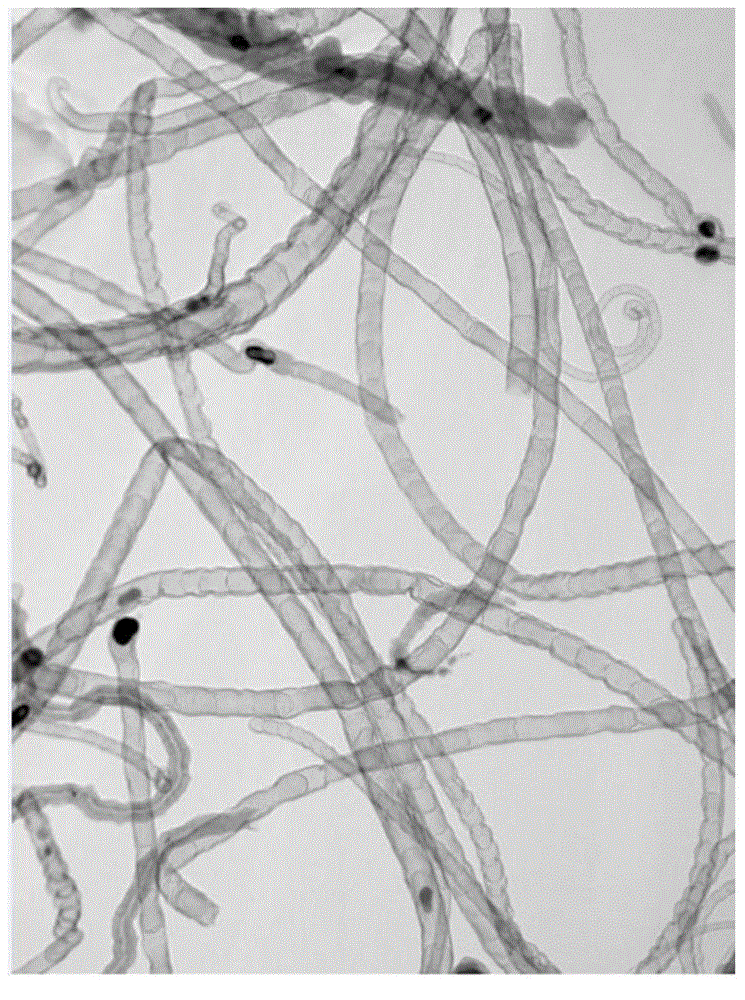

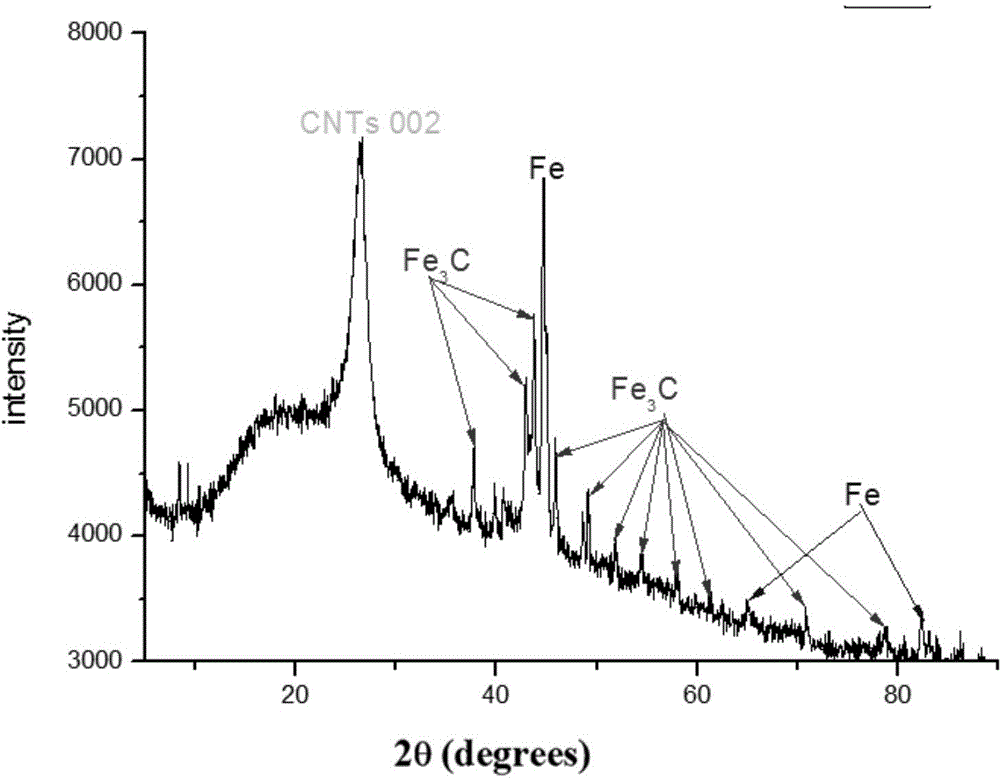

[0034] Characterization of the structure and morphology of the obtained carbon nanotubes

[0035] Adopt the JEM-2000EX transmission electron microscope produced by JEOL Electronics Co., Ltd. of Japan and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com