Method for treating salty sewage of coal chemical industry based on in-furnace combustion

A technology of coal chemical industry and internal combustion, applied in the direction of combustion methods, chemical instruments and methods, combustion types, etc., can solve the problems of accelerating the sintering rate of coal ash, reducing the sintering temperature of coal ash, increasing the sintering strength, etc., and achieves strong practicability , reduce processing costs, and facilitate equipment maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

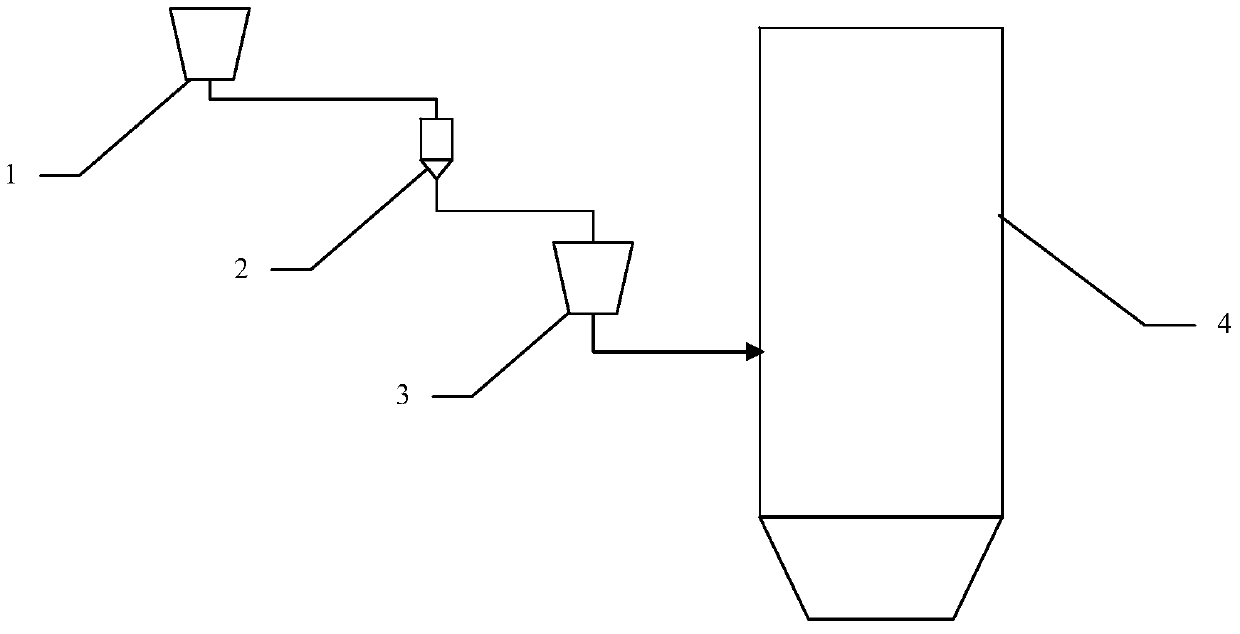

[0022] The principle, specific structure and best implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Evaporating and concentrating the coal chemical sewage into crystals and then adding them to the boiler for blending combustion. It is characterized in that the solid crystals formed by the crystallization equipment 1 are added to the premixing equipment 3 through the feeding equipment 2. For circulating fluidized bed boilers, The pre-mixing equipment 3 can be a limestone bin, at this time, the crystallized matter enters the boiler 4 with the limestone for blending; for the pulverized coal boiler, the pre-mixed device can be a coal mill, at this time, the crystallized matter enters the boiler 4 for blending with the pulverized coal burn. The premixing equipment 3 can be any equipment in the boiler feed equipment, not limited to the proposed equipment.

[0024] The maximum treatment capacity of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com