Method for extracting folic acid from soybeans

A soybean and folic acid technology, applied in the direction of organic chemistry, color/spectral property measurement, etc., can solve the problems of low sensitivity, difficult folic acid quantification, interference with folic acid determination, etc., and achieve the effect of reducing experimental errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

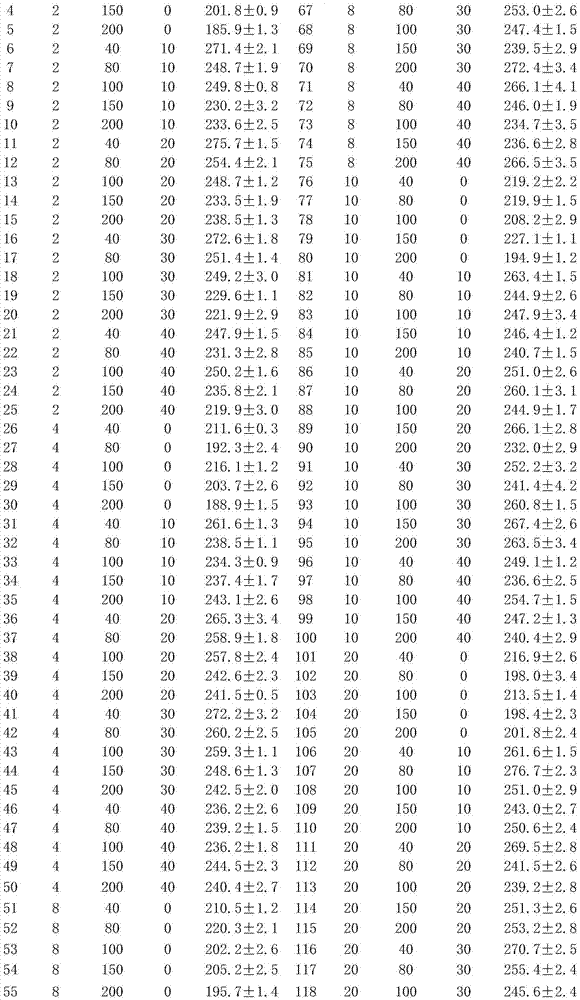

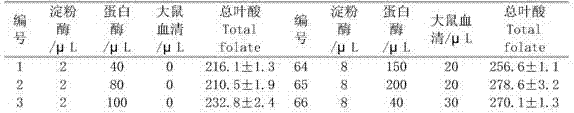

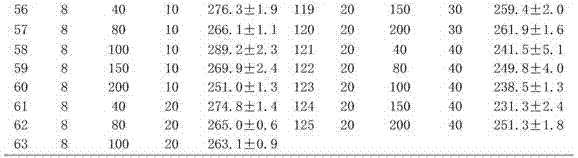

Examples

Embodiment 1

[0031] Embodiment 1 soybean sample preparation

[0032] Soybean seeds were crushed to obtain soybean powder, and 0.2 g of soybean powder was weighed, placed in a 2 mL LAXYGENEP tube, and repeated three times. Add 750μL of folic acid extraction buffer (50mM phosphate buffer, PH=6.5, 1% sodium ascorbate, 0.1% 2-mercaptoethanol) to each sample, incubate at 95°C for 15min and place on ice to cool, then add 5mm steel beads , grind the sample in a tissue grinder (1400 rpm for 5 min). The sample grinding process needs to be protected from light.

Embodiment 2

[0033] Example 2 Soybean folic acid extraction

[0034] Add 8 μL α-amylase and 750 μL folic acid extraction buffer to the sample homogenate to avoid viscousness, place at room temperature for 10 minutes, add 100 μL protease, and incubate at 37°C for 1 hour; boil the above mixture at 100°C for 10 minutes to terminate the enzyme action, and quickly cool on ice for 10 minutes Centrifuge at 14,000 rpm for 10 minutes at 4°C; absorb the supernatant, add 10 μL of rat serum to the supernatant according to the volume of 2%, mix well, and incubate at 37°C for 2 hours; boil at 100°C for 10 minutes, put on ice Cool rapidly for 10 minutes; centrifuge at 4°C and 14,000 rpm for 15 minutes; draw the supernatant and put it in a sterile tube for direct measurement or freeze at -80°C. The sample extraction process needs to be protected from light.

Embodiment 3

[0035] The microbial detection method of embodiment 3 soybean folic acid

[0036] (1) Reagent preparation

[0037] Lactic acid bacteria liquid culture medium: add 4.85g of lactic acid bacteria culture medium to 100mL of water, and sterilize at 121°C for 15min.

[0038] Low folic acid medium: Weigh 4.7g of folic acid medium powder, 0.03g of ascorbic acid, and 0.3mL of folic acid standard stock solution, add water to dissolve to 100mL, and sterilize through a 0.22μm filter membrane for later use.

[0039] Analysis buffer: weigh Na 2 HPO 4 .2H 2 O0.38g, NaH 2 PO 4 Dissolve 0.93g and 1g of ascorbic acid in water to make up to 100mL, pass through a 0.22μm membrane filter to sterilize for later use.

[0040] Folic acid medium: Weigh 9.4g of folic acid medium powder, add water to dissolve to a volume of 100mL, boil for 5min, pass through a 0.22μm membrane filter to sterilize for later use.

[0041] (2) Folic acid standard sample preparation

[0042] Weigh 28 mg of folic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com