Preparation method of mixed flame retardant used for spinning

A flame retardant, textile technology, applied in the field of preparation of phosphonate mixed flame retardants for textiles, to achieve the effects of wide application prospects, good mixing uniformity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

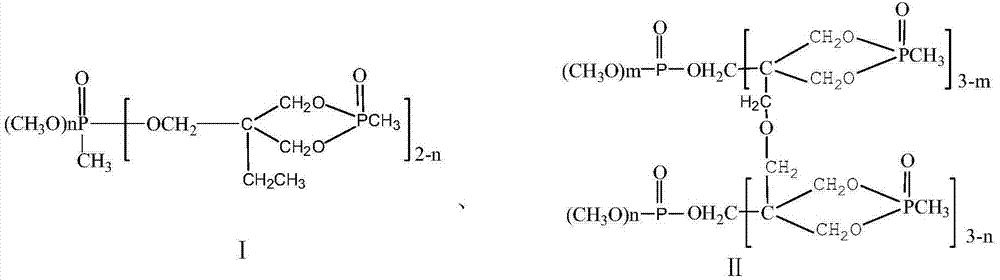

AI Technical Summary

Problems solved by technology

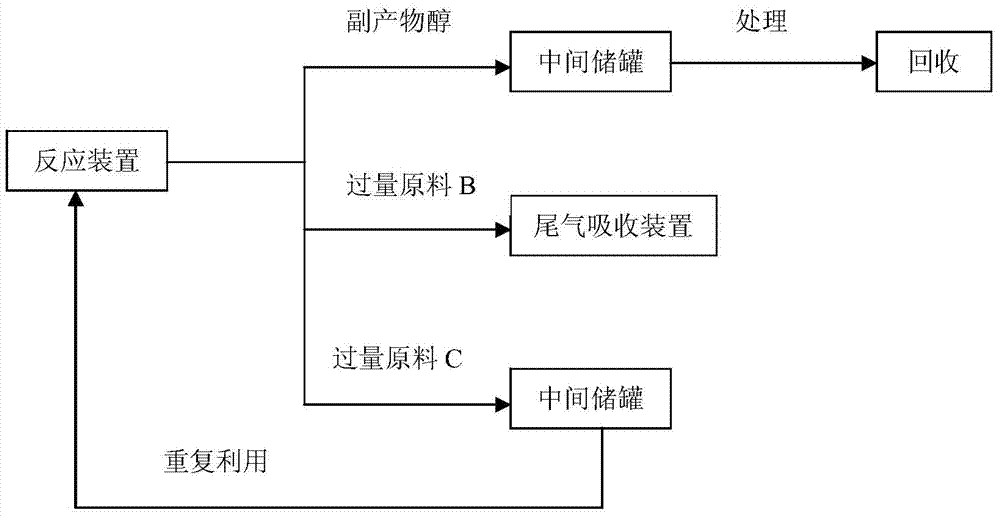

Method used

Image

Examples

Embodiment 1

[0022] In a four-necked flask equipped with a stirrer, a distillation device, a thermometer, and an air duct, add 0.160mol trimethylolpropane, 0.160mol dipentaerythritol, 0.528mol trimethyl phosphite, and 0.006mol phosphoric acid, heat and ventilate nitrogen, Slowly raise the temperature to 85°C, and react at this temperature for 5h to obtain the intermediate and methanol, and distill the methanol out. Then add 0.336mol dimethyl methylsulfate and 0.007mol butyl bromide to the intermediate, react at 185°C for 16h, and remove excess dimethylmethylsulfate (applied mechanically) under reduced pressure to obtain a free Color transparent viscous liquid 110.362g, yield 95.8%.

Embodiment 2

[0024] In a four-neck flask equipped with a stirrer, a distillation device, a thermometer, and an air duct, add 0.100mol trimethylolethane, 0.200mol dipentaerythritol, 0.55mol triethyl phosphite, and 0.002mol polyphosphoric acid, heat and Nitrogen was blown, and the temperature was slowly raised to 85° C., and reacted at this temperature for 5 hours to obtain the intermediate and ethanol, and the ethanol was distilled off. Then add 0.350mol triethyl phosphate and 0.008mol bromoisobutane to the intermediate, react at 185°C for 16h, remove excess triethyl phosphate under reduced pressure (applicable), and obtain a colorless transparent viscous liquid 126.275 g, yield 96.1%.

Embodiment 3

[0026] In a four-necked flask equipped with a stirrer, a distillation device, a thermometer, and an air duct, add 0.110mol of dipentaerythritol, 0.230mol of trimethylolpropane, 0.495mol of tributyl phosphite, and 0.011mol of sulfuric acid, heat and ventilate nitrogen, Slowly raise the temperature to 85°C, and react at this temperature for 5h to obtain the intermediate and butanol, and distill the butanol out. Add 0.385 mol of trimethyl phosphate and 0.009 mol of bromopentane to the intermediate, react at 185°C for 16 hours, remove excess trimethyl phosphate under reduced pressure (applicable), and obtain 113.726 g of a colorless transparent viscous liquid. Yield 95.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com