Cultivation method for controlling bacillus not to generate odor

A bacillus and odor technology, applied in the field of microbial fermentation, can solve the problems of bacillus odor, bad smell, smelly taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Strain Activation of Bacillus thuringiensis LG1

[0022] Streak inoculation of Bacillus thuringiensis LG1 stored in a glycerol tube at -80°C on a solid medium was placed in a constant temperature incubator at 37°C for 12 hours to obtain a single colony. Composition of solid medium: yeast powder 5g / L, peptone 10g / L, NaCl 10g / L, agar 20g / L, initial pH 7.0.

[0023] 2. Seed liquid culture of Bacillus thuringiensis LG1

[0024] Pick a single colony on the solid medium and inoculate it into the seed medium, and the liquid volume of the shake flask seed medium is 25 / 250mL. Cultivate on a shaker at 37° C. and 220 r / min for 12 hours to obtain seed liquid. The composition of the seed medium: yeast powder 5g / L, peptone 10g / L, NaCl 10g / L, initial pH 7.0.

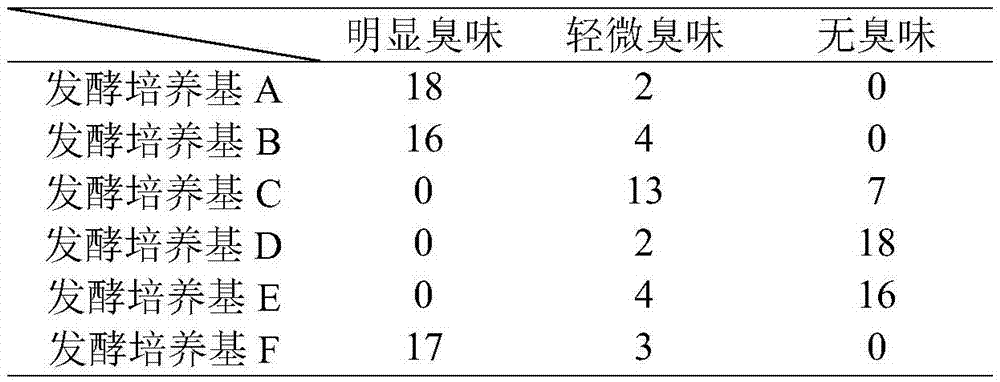

[0025] 3. Cell fermentation of Bacillus thuringiensis LG1

[0026] Inoculate the seed liquid obtained in step 2 into the fermentation medium (A~F) according to the inoculation amount of 5%, and then ferment and cultivate ...

Embodiment 2

[0039] 1. Strain activation of Bacillus amyloliquefaciens JY06

[0040] Bacillus amyloliquefaciens JY06 stored in a glycerol tube at -80°C was streak-inoculated on the solid medium, and cultured in a constant temperature incubator at 37°C for 12 hours to obtain a single colony. Composition of solid medium: yeast powder 5g / L, peptone 10g / L, NaCl 10g / L, agar 20g / L, initial pH 7.0.

[0041] 2. Seed liquid culture of Bacillus amyloliquefaciens JY06

[0042] Pick a single colony on the solid medium and inoculate it into the seed medium, and the liquid volume of the shake flask seed medium is 25 / 250mL. Cultivate on a shaker at 37° C. and 220 r / min for 12 hours to obtain seed liquid. The composition of the seed medium: yeast powder 5g / L, peptone 10g / L, NaCl 10g / L, initial pH 7.0.

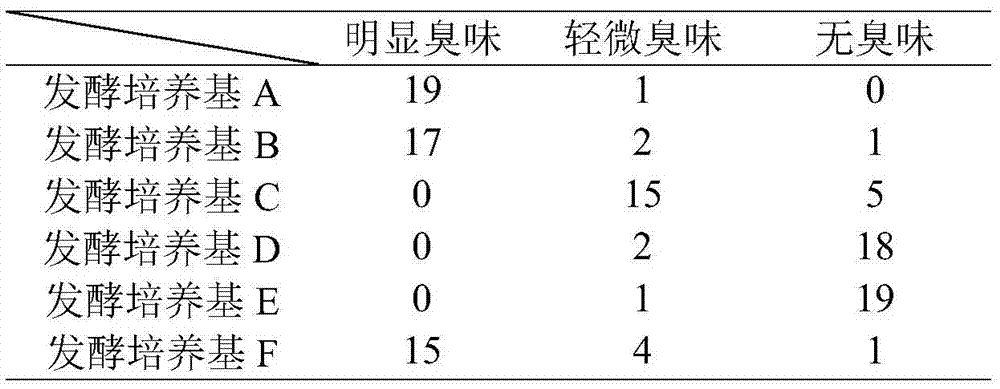

[0043] 3. Cell fermentation of Bacillus amyloliquefaciens JY06

[0044] Inoculate the seed liquid obtained in step 2 into the fermentation medium (A~F) according to the inoculation amount of 5%, and th...

Embodiment 3

[0057] 1. Strain Activation of Bacillus subtilis LG2

[0058] Streak inoculation of Bacillus subtilis LG2 stored in a glycerol tube at -80°C on a solid medium was placed in a constant temperature incubator at 37°C for 12 hours to obtain a single colony. Composition of solid medium: yeast powder 5g / L, peptone 10g / L, NaCl 10g / L, agar 20g / L, initial pH 7.0.

[0059] 2. Seed liquid culture of Bacillus subtilis LG2

[0060] Pick a single colony on the solid medium and inoculate it into the seed medium, and the liquid volume of the shake flask seed medium is 25 / 250mL. Cultivate on a shaker at 37° C. and 220 r / min for 12 hours to obtain seed liquid. The composition of the seed medium: yeast powder 5g / L, peptone 10g / L, NaCl 10g / L, initial pH 7.0.

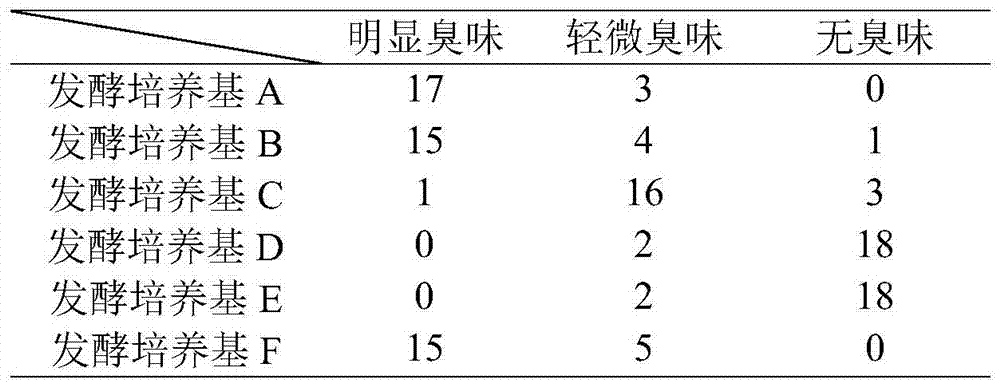

[0061] 3. Cell fermentation of Bacillus subtilis LG2

[0062] The seed solution obtained in step 2 is inoculated in the fermentation medium (A-F) according to the inoculum amount of 5%, and then fermented and cultivated at 37° C. and 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com