Self-concentric brush seal structure with rotor provided with discs

A technology of brush seals and discs, which is applied in the direction of supporting elements of blades, leakage prevention, mechanical equipment, etc., can solve the problem of accelerating brush wire and rotor surface friction, reducing the sealing performance of brush seals, increasing gas leakage, etc. problem, achieve the effect of reducing the stiffening effect and hysteresis effect, improving the performance of the brush seal, and improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

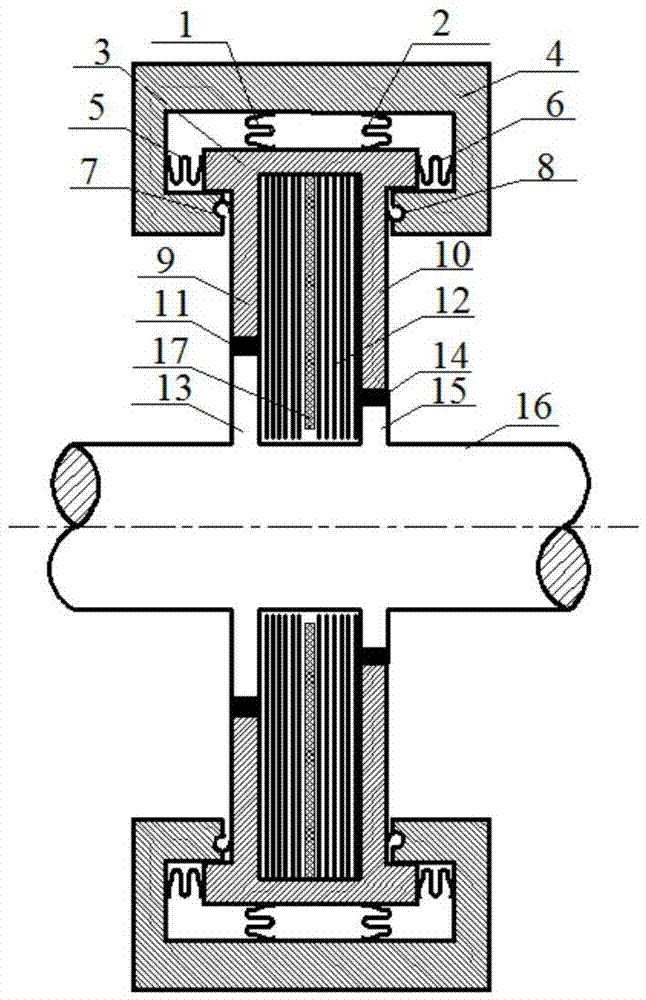

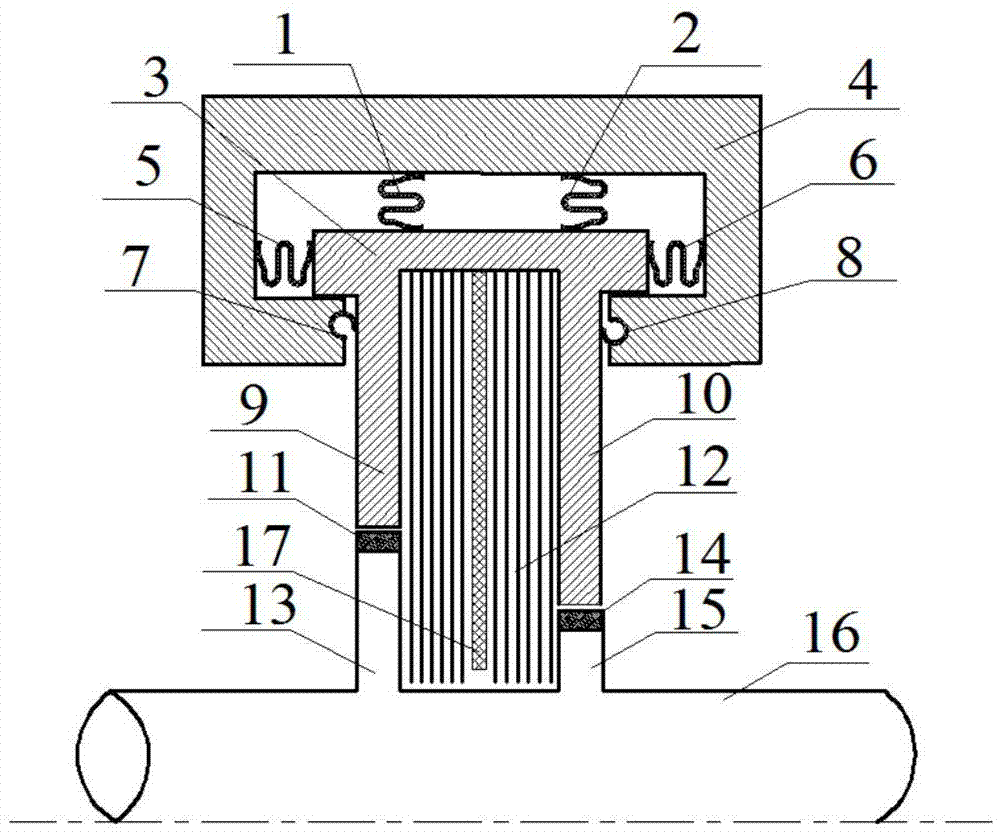

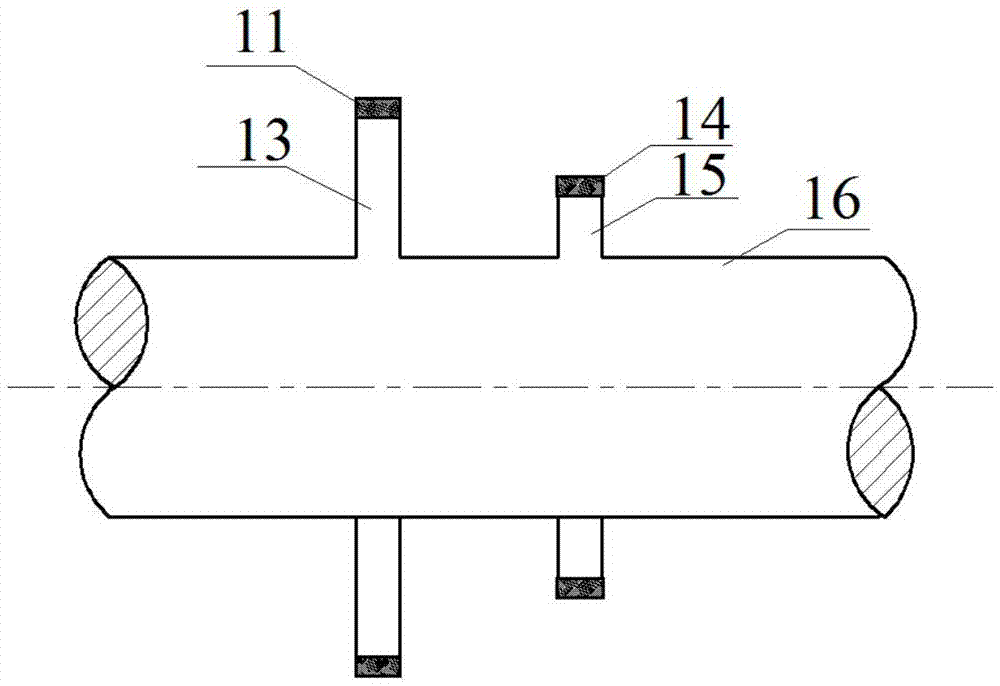

[0024] Such as Figure 1-Figure 3 Shown: a self-concentric brush seal structure with discs in the rotor, including radial W-shaped seal rings 1 and 2, welding zone 3, stator case 4, axial W-shaped seal rings 5 and 6, C Type sealing ring 7,8, front baffle plate 9, back baffle plate 10, wear-resistant coating 11,14, brush wire bundle 12, front disc 13, rear disc 15, rotor 16, bearing plate 17. The brush seal is composed of a welding zone 3, a front baffle 9, a rear baffle 10 and a brush wire bundle 12, and a certain radial gap is maintained between the brush seal and the stator casing 4 to ensure that the brush seal Can move radially freely; C-shaped sealing rings 7 and 8 are located on the neck surface of the front and rear baffles to cooperate with the stator casing 4, and the openings of C-shaped sealing rings 7 and 8 are connected with the high-pressure side, self-expanding under the action of pressure difference, A good seal is achieved. The pressure bearing plate 17 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com