Kilowatt-level rock output three-redundancy electro-hydraulic digital servo system

A digital servo and three-redundancy technology, which is applied in fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc. Mechanism reliability can not be guaranteed and other problems, to achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

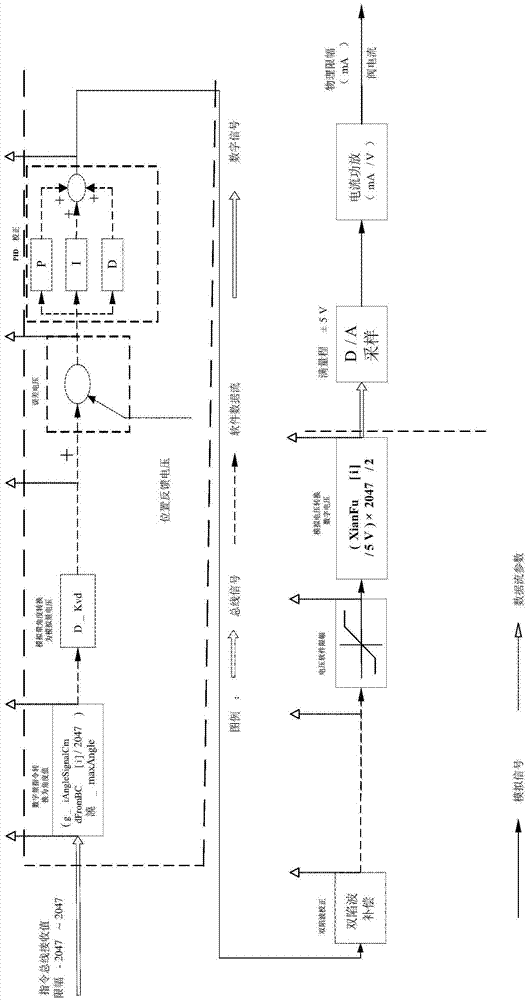

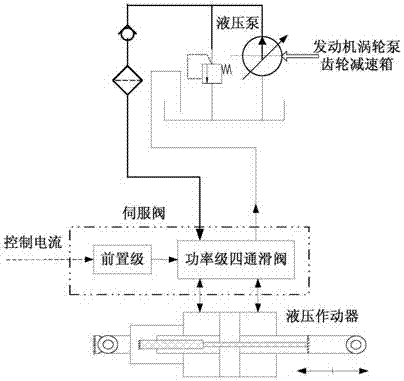

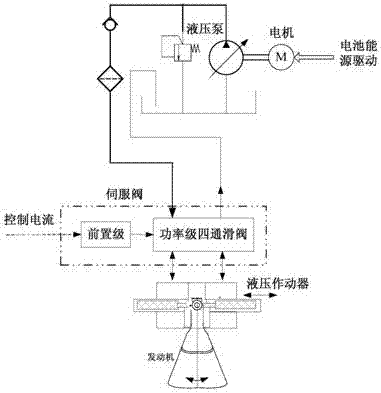

[0038] The basic idea of the invention is: a three-redundant electro-hydraulic digital servo system based on kilowatt-level swing output. In essence, the three-degree redundancy is to adopt redundant design for the fault-prone links such as the pre-stage of the electro-hydraulic servo valve, the feedback potentiometer of the actuator, the key control link, and the closed-loop control of the position of the servo controller, so as to realize the "failure of the servo mechanism control Fault tolerance”; digitalization essentially means that the electro-hydraulic servo valve cancels the traditional dynamic pressure feedback device and replaces it with algorithm compensation for the digital servo controller to achieve high dynamic response requirements and has the advantage of flexible parameter adjustment. In addition, the kilowatt-level swing output triple-redundant electro-hydraulic digital servo system adopts a high-speed, high-specific-power DC motor and a fast-response dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com