Boron nitride/resin composite circuit board, and circuit board including boron nitride/resin composite integrated with heat radiation plate

A technology of circuit substrate and boron nitride, which is applied in the direction of circuit substrate material, circuit thermal device, printed circuit dielectric, etc. stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11~1-13

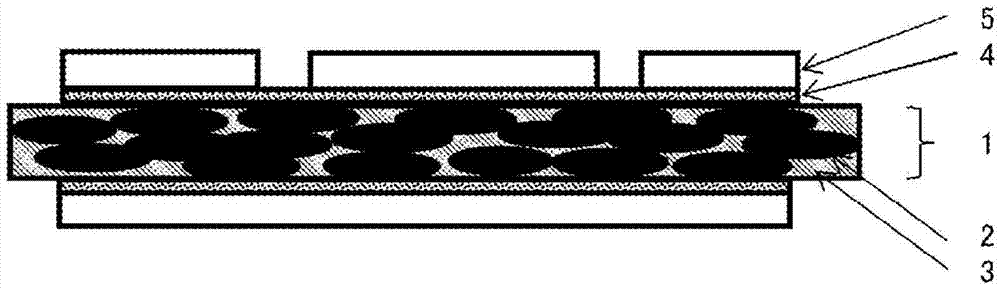

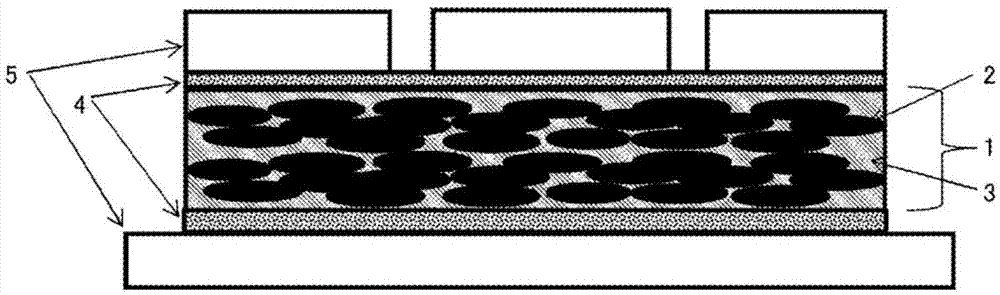

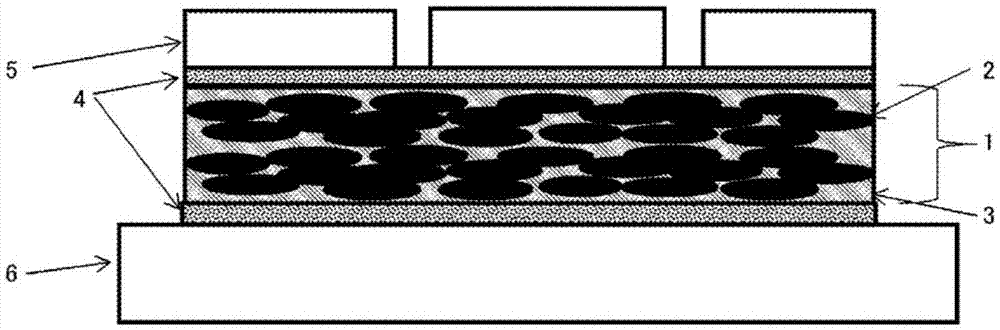

[0180] The obtained boron nitride sintered body was impregnated with resin. A mixture of boron nitride sintered body, epoxy resin ("Epikote807" manufactured by Mitsubishi Chemical Corporation) and curing agent ("AkuMexH-84B" manufactured by Nippon Gosei Chemical Co., Ltd.) was degassed in a vacuum at a pressure of 70 Pa for 20 minutes, and then The epoxy resin mixture was injected into the boron nitride sintered body under vacuum and impregnated for 30 minutes. Thereafter, nitrogen gas was used to pressurize at a pressure of 3 MPa and a temperature of 120° C. for 30 minutes to impregnate and cure the resin to obtain a boron nitride-resin composite.

Embodiment 1-14

[0182] The boron nitride sintered body and silicone resin (manufactured by "YE5822" Momentive Performance Materials Inc.) were degassed in vacuum at a pressure of 70 Pa for 20 minutes, and then the silicone resin was injected into the boron nitride sintered body under vacuum for 30 minutes. Seep. Thereafter, nitrogen gas was used to pressurize at a pressure of 3 MPa and a temperature of 20° C. for 30 minutes to impregnate the resin, and to heat in a drier at a temperature of 150° C. for 60 minutes to obtain a boron nitride-resin composite.

[0183] The resulting resin-impregnated boron nitride sintered body was processed using a multi-wire saw. At this time, boron nitride particles are cut out so that the 002 plane (c-axis) is oriented in the thickness direction. The evaluation results of the obtained boron nitride sintered body are shown in Tables 1-5.

[0184] [Table 1-5]

[0185]

[0186]

[0187] On the obtained plate-shaped resin-impregnated boron nitride sintered...

Embodiment 2-1

[0201]

[0202] The obtained boron nitride sintered bodies 2A to 2N were impregnated with resin. A mixture of boron nitride sintered body, epoxy resin, and curing agent (manufactured by "BondE205" Konishi Co., Ltd.) was degassed for 10 minutes in a vacuum at a pressure of 1 mmHg, and then injected into the boron nitride sintered body under vacuum, The impregnation was carried out for 20 minutes. Thereafter, heating was performed at a temperature of 150° C. for 60 minutes under atmospheric pressure to cure the resin, thereby obtaining a resin-impregnated boron nitride sintered body with a thickness of 100 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com