Catalyst unified plasma nitric oxide removing device and method

A technology of plasma and nitrogen oxides, which is applied in the field of flue gas denitrification, can solve the problems of not being widely used, dust accumulation in the air preheater, and large amount of operation and maintenance, and achieves stable operation, small footprint, and economical High benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

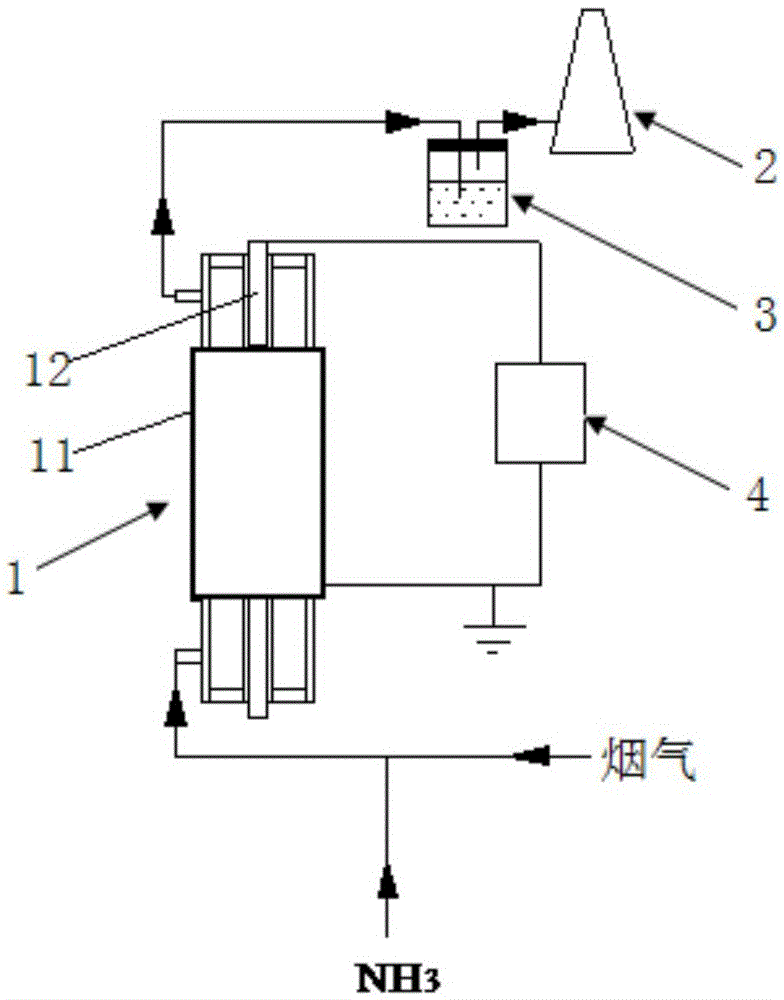

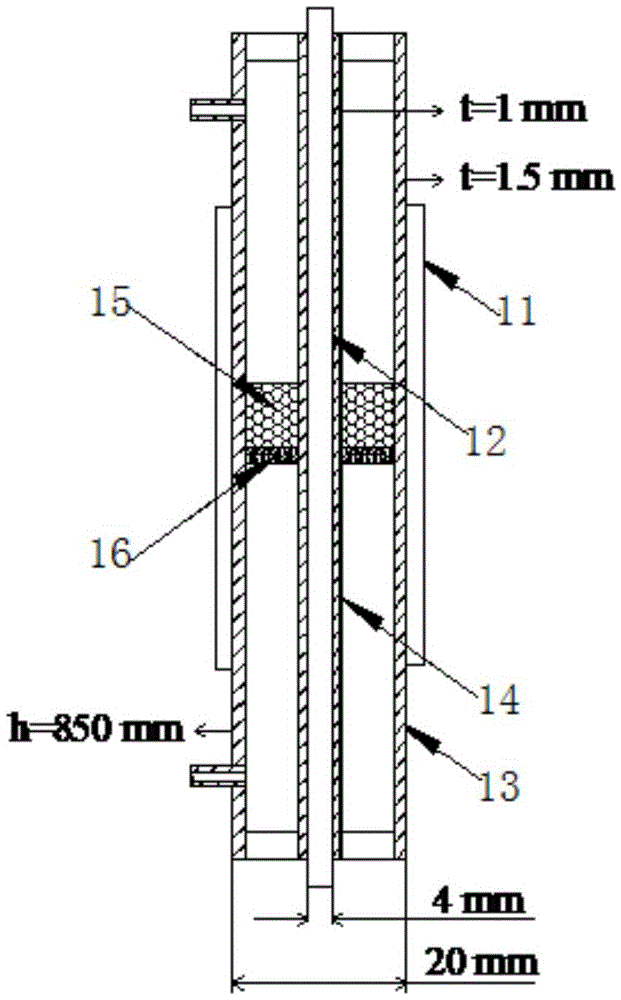

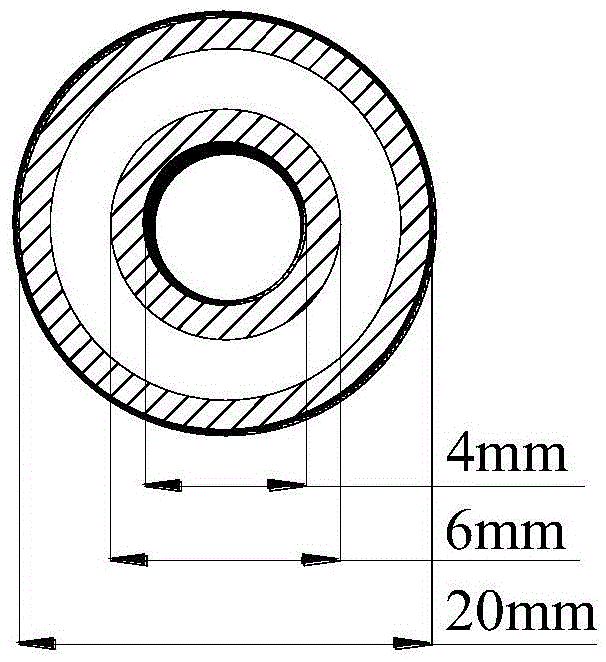

[0032] In order to realize the efficient removal of nitrogen oxides, the present invention provides a novel flue gas denitrification method, the process flow is as follows figure 1 As shown, after the combustion flue gas is mixed with the reducing gas ammonia, it is passed into the reactor 1 from the lower part, Figure 2-3 It is a structural cross-sectional view of a double dielectric barrier discharge reactor. The reactor 1 is a double dielectric layer formed by an outer dielectric pipe 13 and an inner dielectric pipe 14. The axes of the outer dielectric pipe 13 and the inner dielectric pipe 14 are on a straight line. Both are made of quartz material, the thicknesses are 1.5 mm and 1 mm respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com