Polyamide reverse osmosis composite membrane having renewable chlorine resistance and preparation method thereof

A reverse osmosis composite membrane, polyamide technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as easy falling off, and achieve the effect of strengthening chlorine resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

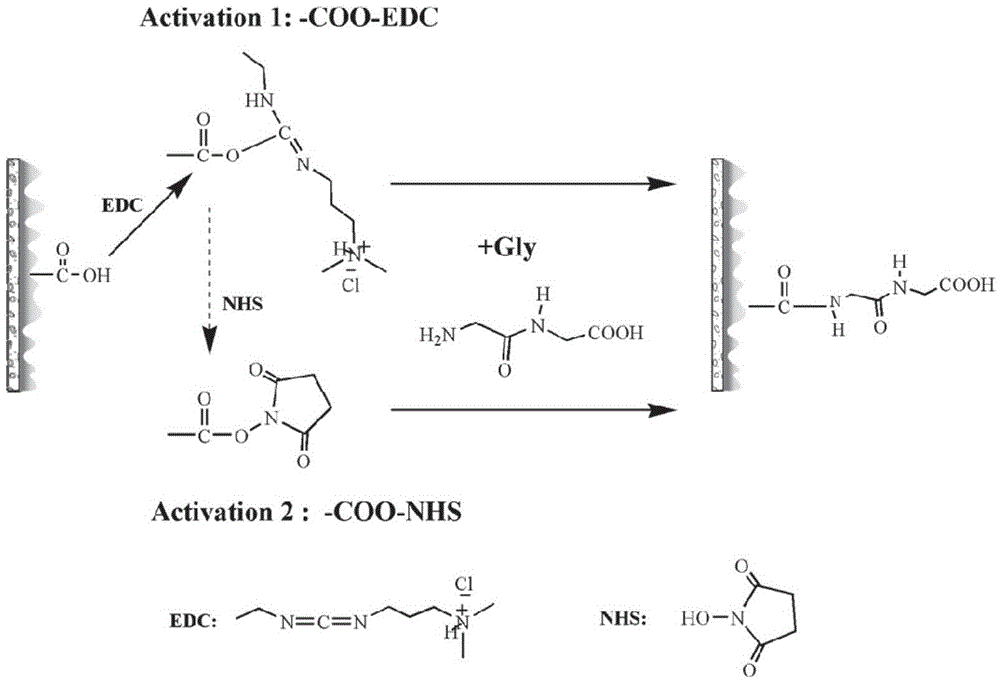

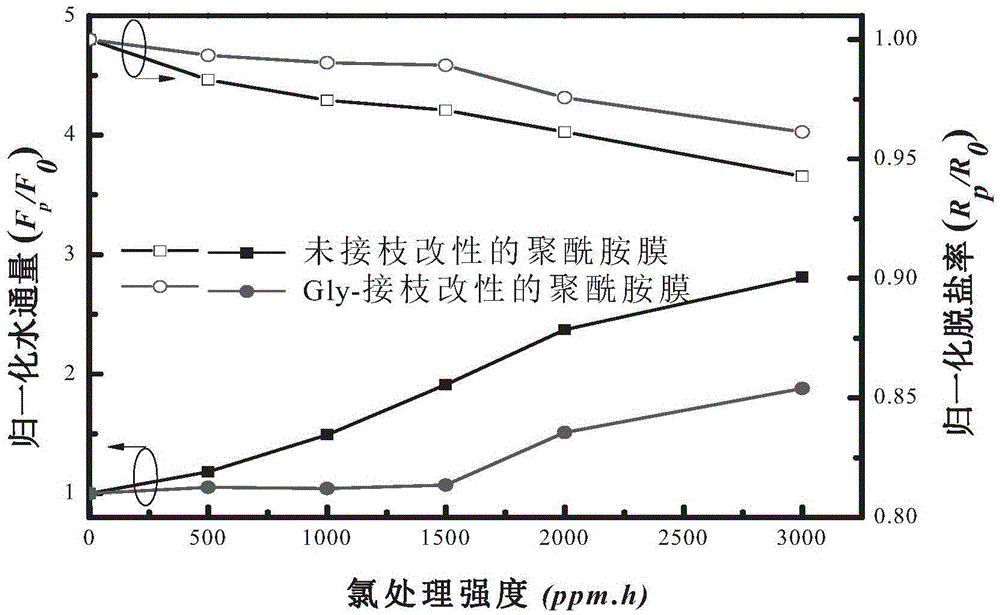

[0064] Immerse the raw polyamide membrane (21cm×14cm) prepared above without surface graft modification into the catalyst, shake it at 37°C and 80r / min for 1h, then wash the surface of the membrane with deionized water to remove free Catalyst: Pour 150mL of phosphate buffer solution containing glycylglycyl peptide (Gly) into the surface of the membrane activated by the catalyst, shake and react at 37°C and 80r / min for 2h, fully wash the surface of the membrane with deionized water, and remove residual mono In bulk, the membrane was kept in deionized water.

[0065] The preparation method of the catalyst is: 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) and N-hydroxysuccinimide (NHS) are dissolved in 2-(N -Morpholine) ethanesulfonic acid buffer, adjust the pH of the catalyst to 5-6 with hydrochloric acid or sodium hydroxide; 2-(N-morpholine) ethanesulfonic acid buffer contains 0.1mol / L of 2-( N-morpholine) ethanesulfonic acid (MES) and 0.5mol / L NaOH.

[00...

Embodiment 2、3

[0069] Compared with Example 1, the difference lies in that the mass percent concentrations of Gly in the phosphate buffer solution are 0.35% and 0.15%, respectively.

Embodiment 4~6

[0071] Compared with Example 1, the difference is that Gly is replaced by glutamine (Gln), and the mass percentage concentrations of Gln in the phosphate buffer solution are 0.15%, 0.25%, and 0.35%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com