Method for efficiently making large-depth-diameter-ratio micropore arrays

A technology with high aspect ratio and microhole array, which is applied in the field of femtosecond laser application, can solve the problems of fast processing and low processing efficiency of microhole array, and achieve the effect of improving processing efficiency

Inactive Publication Date: 2016-04-06

BEIJING INSTITUTE OF TECHNOLOGYGY

View PDF5 Cites 44 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

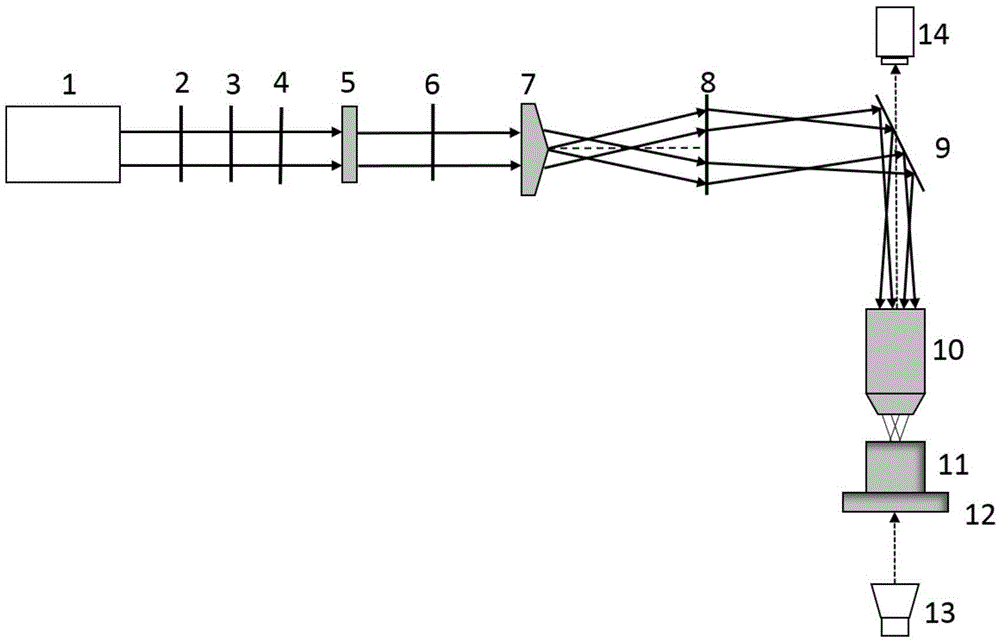

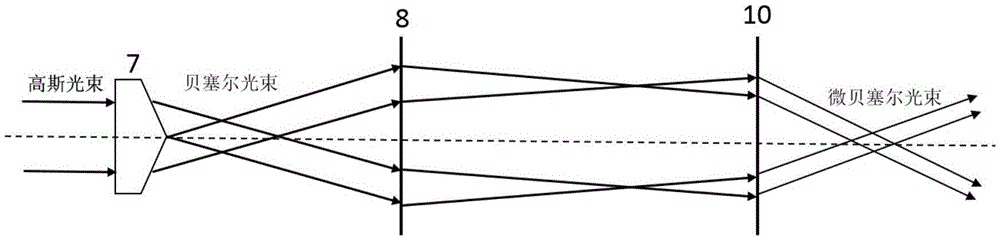

[0005] The purpose of the present invention is to solve the problem that the processing efficiency of high-quality, high-depth-diameter ratio microhole arrays is low, and it is impossible to quickly process large-area high-depth-diameter ratio microhole arrays in a relatively short period of time. A method for efficiently processing microhole arrays with a high depth-to-diameter ratio with Bessel beams. The present invention regulates the transient electron density in the laser irradiation area by shaping the spatial light of the femtosecond laser, and combines the "time-of-flight drilling method" of the femtosecond laser ( JournalofLaser Applications, 4(2), 15-24, 1992), realizing efficient processing of large-area microhole arrays with high aspect ratio

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0029] 1- The femtosecond laser system adopts the laser produced by American SpectraPhysics (SpectraPhysics). The laser wavelength is 800nm, the pulse width is 50 femtoseconds, the repetition frequency is adjustable at 1KHz, the maximum single pulse energy is 3mJ, and the light intensity distribution is Gaussian. polarization.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a method for efficiently machining large-depth-diameter-ratio micropore arrays through a femtosecond laser Bessel beam, and belongs to the technical field of femtosecond laser application. According to the method, a femtosecond laser space light shaping method and a flight time punching method are integrated, the properties of small spot diameter and long focal depth of the femtosecond laser Bessel beam are effectively utilized, and a large area of large-depth-diameter-ratio micropore arrays can be efficiently machined within a short time. The depth-diameter ratio of the zero-taper micropores continuously machined under the single laser pulse condition reaches up to 330:1, the machining quality and machining efficiency of the micropore arrays are greatly improved, and the method has crucial application value in optics, optical instruments, aviation, biomedicine and the like.

Description

technical field [0001] The invention relates to a method for processing a microhole array with a high depth-to-diameter ratio, in particular to a method for efficiently processing a microhole array with a high depth-to-diameter ratio by using a femtosecond laser Bessel beam, and belongs to the technical field of femtosecond laser applications. Background technique [0002] Micropore manufacturing has extremely important applications in aerospace, optoelectronics, microfluidic devices and other related fields. With the continuous progress and development of laser technology, research on micropore manufacturing has very important practical significance. The advantage of laser microhole manufacturing is that it has better flexibility and higher degree of automation. In addition, compared with traditional mechanical processing technology, laser microhole manufacturing technology is a non-contact technology, and the processing tools will not be affected by the hardness of the proc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K26/382B23K26/06B23K26/064

CPCB23K26/0648B23K26/0652

Inventor 姜澜谢乾李晓炜

Owner BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com