Ion-covalent double-network hydrogel and preparation method thereof

A hydrogel and double-network technology, applied in the field of ion-covalent double-network hydrogel and its preparation, can solve the problems of limited application and achieve good anti-swelling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

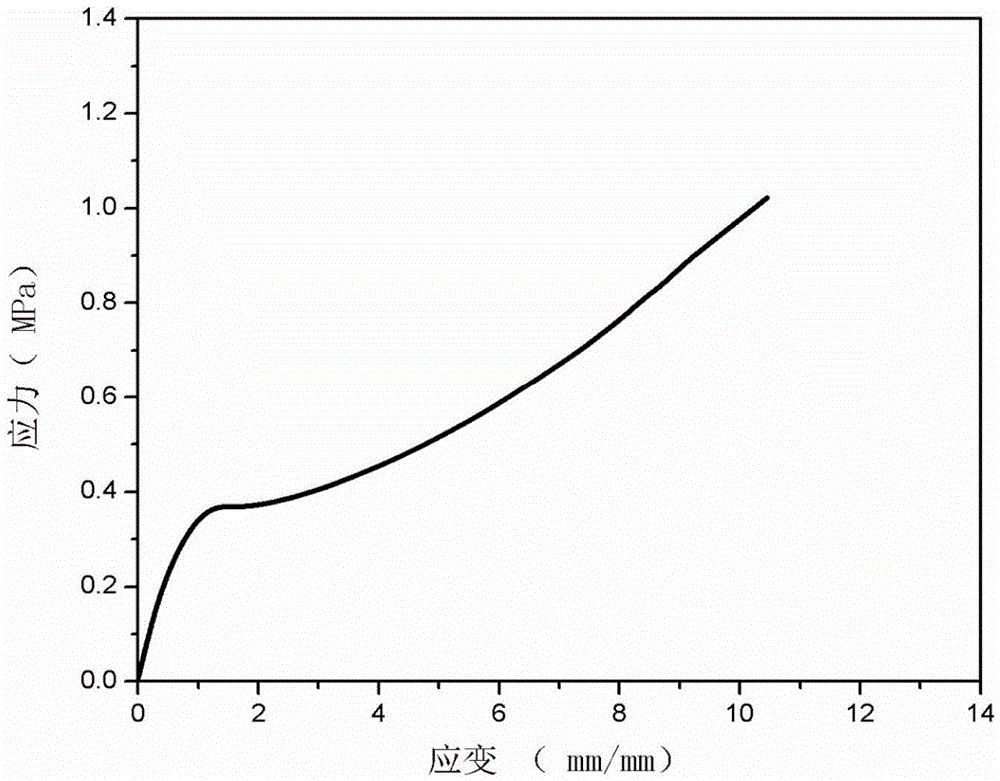

[0032] Mix 6.222g of acrylamide, 0.778g of sodium carboxymethylcellulose with a degree of substitution of 1.2, 0.024g of potassium persulfate, and 5.4mg of N,N'-methylenebisacrylamide into a 50mL aqueous solution, stir and mix evenly, and add dropwise 23μL N,N,N',N'-Tetramethylethylenediamine (TEMED), stir and mix evenly, transfer the prepared prepolymer solution to a mold composed of silicone rubber and glass sheet with a thickness of 2mm, and react at 50°C for 3 The semi-interpenetrating network hydrogel can be obtained within hours. Soak this semi-IPN hydrogel in 50mL of 0.10mol / L iron ion solution for 24 hours, then soak the hydrogel soaked in iron ions in deionized water for 48 hours to obtain the covalent Double network hydrogel. The stress-strain curve figure of ioncovalent double network hydrogel obtained in the present embodiment is as follows figure 1 shown. Depend on figure 1 It can be seen that the ioncovalent double network hydrogel obtained in the present inv...

Embodiment 2

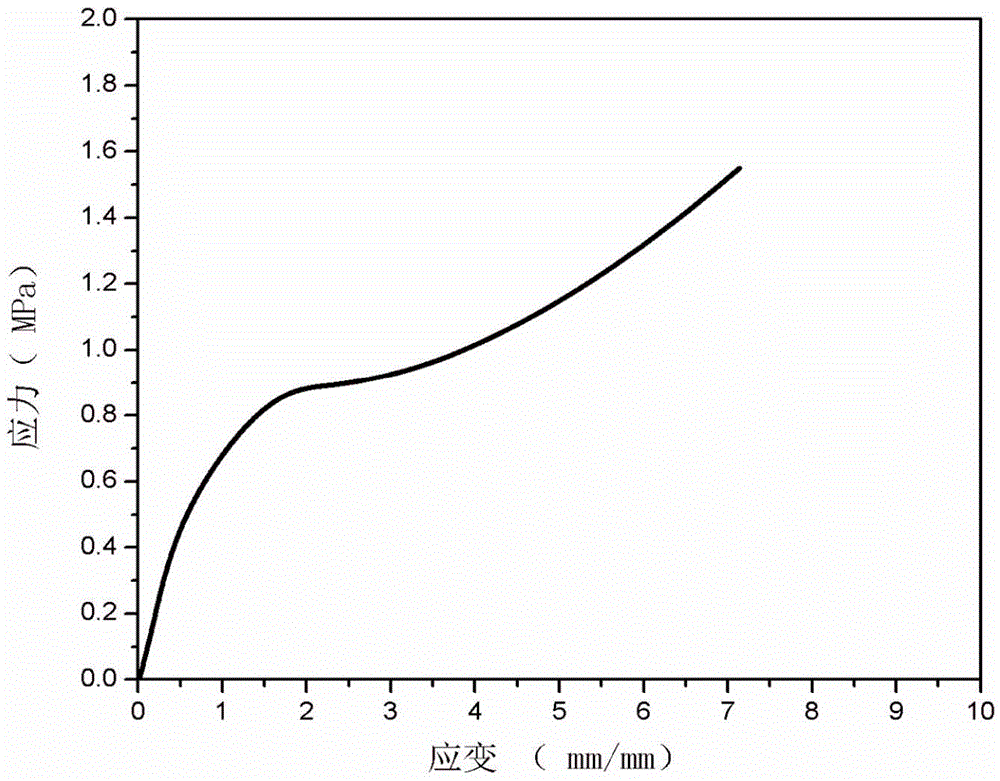

[0034] 10.222g of acrylamide, 1.278g of sodium carboxymethylcellulose with a degree of substitution of 1.2, 0.039g of potassium persulfate, and 22.1mg of N,N'-methylenebisacrylamide were made into a 50mL aqueous solution, and after mixing evenly, dropwise added 38μL N,N,N',N'-Tetramethylethylenediamine (TEMED), stir and mix evenly, transfer the prepared prepolymer solution to a mold composed of silicone rubber and glass sheet with a thickness of 2mm, and react at 50°C for 3 The semi-interpenetrating network hydrogel can be obtained within hours. Soak this semi-IPN hydrogel in 50mL of 0.50mol / L iron ion solution for 24 hours, then soak the hydrogel soaked in iron ions in deionized water for 48 hours to obtain the covalent Double network hydrogel. The stress-strain curve figure of ioncovalent double network hydrogel obtained in the present embodiment is as follows figure 2 shown. Depend on figure 2 It can be seen that the ioncovalent double network hydrogel obtained in the...

Embodiment 3

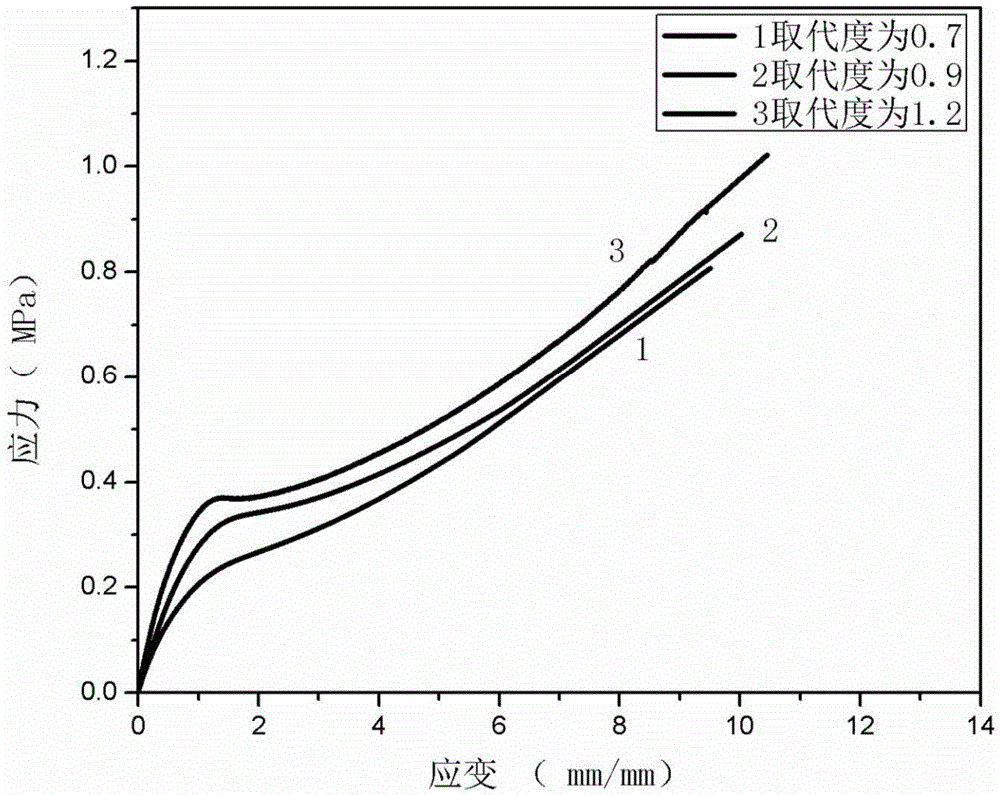

[0036] Mix 6.222g of acrylamide, 0.778g of sodium carboxymethylcellulose with degrees of substitution of 0.7, 0.9 and 1.2, 0.024g of potassium persulfate, and 5.4mg of N,N'-methylenebisacrylamide into a 50mL aqueous solution, stir and mix After uniformity, add 23 μL N,N,N',N'-tetramethylethylenediamine (TEMED) dropwise, stir and mix evenly, and then transfer the prepared prepolymer solution to a mold composed of silicone rubber and glass sheet with a thickness of 2mm The semi-interpenetrating network hydrogel can be obtained by reacting at 50°C for 3 hours. Soak this semi-IPN hydrogel in 50mL of 0.10mol / L iron ion solution for 24 hours, then soak the hydrogel soaked in iron ions in deionized water for 48 hours to obtain the covalent Double network hydrogel. The stress-strain curves of three kinds of ioncovalent double network hydrogels with different degrees of substitution obtained in this example are as follows: image 3 shown. Depend on image 3It can be seen that the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com