High-fluidity, scratch-resistant and low-temperature-resistant brominated flame-retardant ABS (acrylonitrile-butadiene-styrene)/TPU (thermoplastic polyurethane) alloy material as well as preparation method and application thereof

A kind of alloy material, bromine flame retardant technology, applied in the field of ABS modified composite materials, to achieve the effect of convenient operation, simple process and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

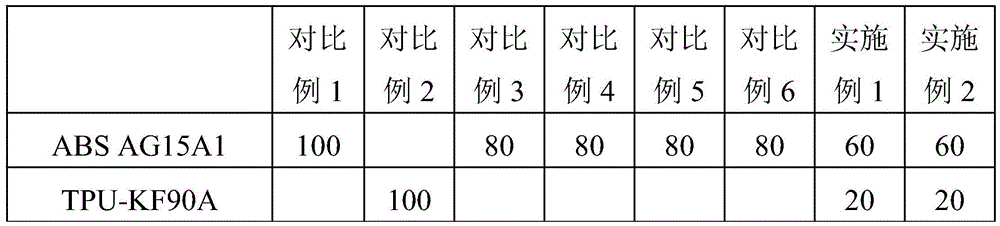

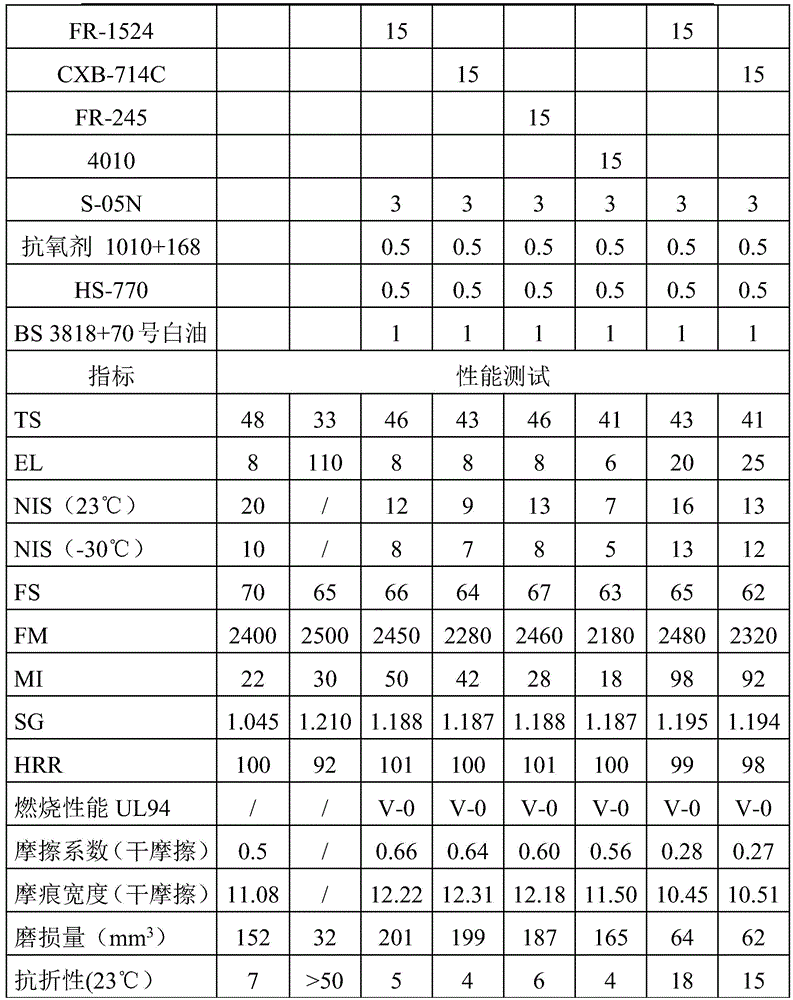

[0024] The present invention will be further described below through specific examples. The following examples are preferred embodiments of the present invention, but the embodiments of the present invention are not limited by the following examples.

[0025] The raw materials used in the examples and comparative examples are now described as follows, but not limited to these materials: ABS resin is selected from Taiwan Taihua ABSAG15A1; thermoplastic polyurethane TPU is selected from Taiwan Hongyi TPU-KF90A; Tetrabromobisphenol A is selected from Israel Dead Sea bromine The company's FR-1524; brominated epoxy uses CXB-714C from Korea Woojin; decabromodiphenylethane uses 4010 from American Albemarle; brominated triazine uses FR-245 from Israel's Dead Sea Bromine Company; antimony flame retardant The agent is S-05N from Huachang Antimony Industry Co., Ltd.; the compatibilizer is AS-MS-NB from NEC; the high rubber powder is HR181 from Kumho Chemical; the light stabilizer is HS-77...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com