A kind of pu matte clear topcoat and preparation method thereof

A clear finish and matte technology, applied in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of human health hazards, air pollution, low solid content, etc., to improve mechanical properties, transparency Good performance and good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with specific embodiments:

[0048] a. Preparation of anti-settling polyamide wax (100Kg each time):

[0049] Weigh 15Kg of 6900-20X, 85Kg of xylene according to the ratio, then mix and disperse it evenly until the fineness is less than or equal to 15μm to obtain the polyamide wax anti-settling slurry;

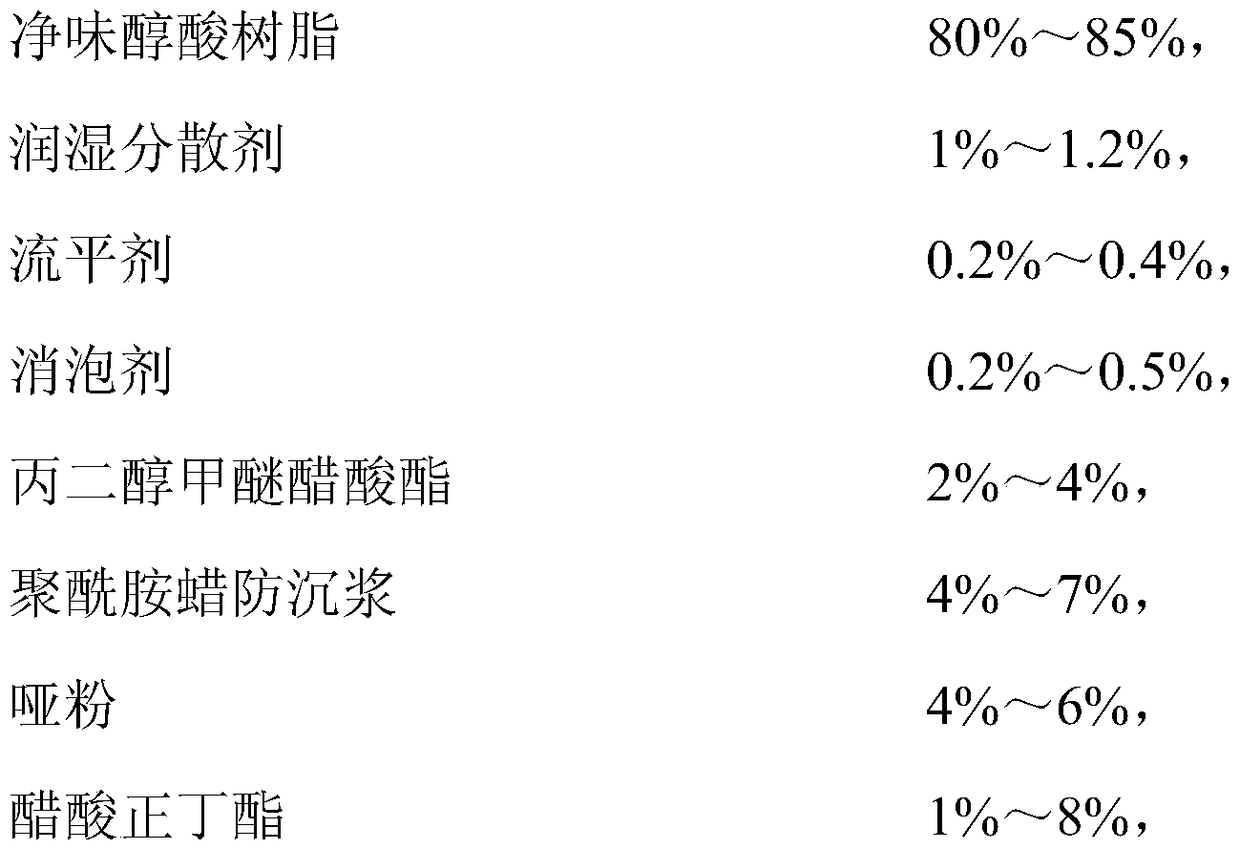

[0050] b. Preparation of component A:

[0051] Weigh each raw material component of component A according to the percentage content of the example in Table 1 below, and sequentially combine the net taste alkyd resin, wetting and dispersing agent, defoaming agent, leveling agent, polyamide wax anti-settling, and propylene glycol After the ether acetate is uniformly dispersed at low speed, put the dumb powder into the dispersion tank, and then disperse at a high speed for 10-15 minutes until the fineness is ≤30μm, and then adjust the viscosity to 2000-2500mpa.s / 25℃ with n-butyl acetate to obtain Compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com