Orange long-afterglow luminescent material and preparation method thereof

A long afterglow luminescence, orange technology, applied in the field of long afterglow luminescent materials and their preparation, high brightness long afterglow luminescent materials and their preparation, can solve problems such as hindering practical applications, long afterglow luminescence color changes, etc., and achieve great application value, The effect of long afterglow time and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of orange long afterglow luminescent material (Ca 0.999 ) 4 Nb 2 O 9 : Pr 0.001 :

[0038] (1) Weigh the raw materials according to Table 1. The above raw materials are all analytically pure, put in an agate mortar, add 30g of absolute ethanol, grind for 3 hours, and then dry in an oven at 60°C;

[0039] (2) Place the dried mixed powder in an alumina crucible and pre-fire at 850°C for 4 hours in an air atmosphere;

[0040] (3) Calcining the ground calcined powder at 1300°C for 4 hours in an air atmosphere;

[0041] (4) Grind the cooled product into powder to obtain a chemical composition of (Ca 0.999 ) 4 Nb 2 O 9 : Pr 0.001 Orange long afterglow luminescent material.

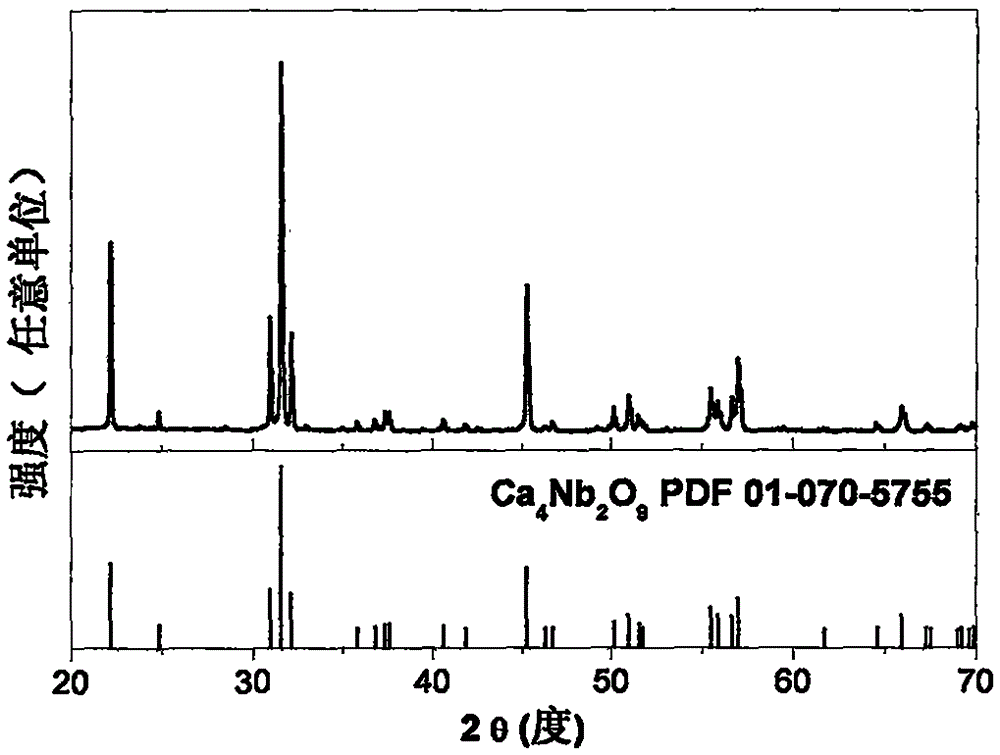

[0042] The orange long afterglow luminescent material prepared in this example has a white appearance, and the X-ray powder diffraction (XRD) test results are as follows figure 1 As shown, the diffraction peak data of the obtained product is compared with Ca 4 Nb 2 O 9 The diffraction data of the powder...

Embodiment 2

[0044] Preparation of orange long afterglow luminescent material (Ca 0.998 ) 4 Nb 2 O 9 : Pr 0.002 :

[0045] (1) Weigh the raw materials according to Table 1. The above raw materials are all analytically pure, put in an agate mortar, add 30g of absolute ethanol, grind for 2 hours, and then dry in an oven at 60°C;

[0046] (2) Place the dried mixed powder in an alumina crucible and pre-fire at 900°C for 4 hours in an air atmosphere;

[0047] (3) Calcining the ground calcined powder at 1400°C for 4 hours in an air atmosphere;

[0048] (4) Grind the cooled product into powder to obtain a chemical composition of (Ca 0.998 ) 4 Nb 2 O 9 : Pr 0.002 Orange long afterglow luminescent material.

Embodiment 3

[0050] Preparation of orange long afterglow luminescent material (Ca 0.997 ) 4 Nb 2 O 9 : Pr 0.003 :

[0051] (1) Weigh the raw materials according to Table 1. The above raw materials are all analytically pure, put into an agate mortar, add 35g deionized water and grind for 2.5 hours, then dry in an oven at 70°C;

[0052] (2) Place the dried mixed powder in an alumina crucible and pre-fire at 950°C for 5 hours in an air atmosphere;

[0053] (3) Calcining the ground calcined powder at 1450°C for 5 hours in an air atmosphere;

[0054] (4) Grind the cooled product into powder to obtain a chemical composition of (Ca 0.997 ) 4 Nb 2 O 9 : Pr 0.003 Orange long afterglow luminescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com