Environment-friendly concentrated solution and preparation method thereof

A concentrated, environmentally friendly technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of complex process and various types of materials, and achieve the effect of simple preparation method, meeting environmental protection requirements, and good cleaning performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present invention prepares the used raw material formula of 1 ton of concentrated solution as follows:

[0024] Element

Dosage(KG)

Element

Dosage(KG)

water

479

20

EDTA

40

240

Triethanolamine Oleic Acid Soap

40

20

30

Emulsifier TX-10

10

1

Glycerin

120

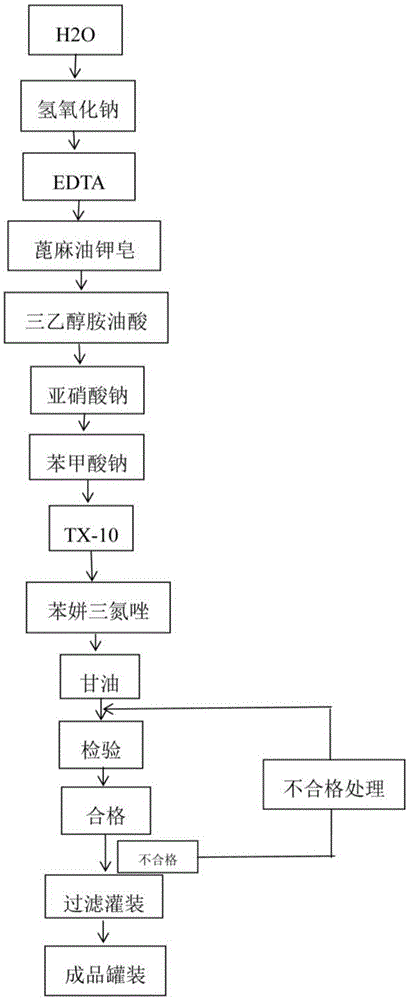

[0025] Such as figure 1 Shown, the complete steps of the preparation method of the inventive method:

[0026] 1) Under the condition that the temperature is not lower than 20°C and the stirring rate is not lower than 45r / min, first add sodium hydroxide, EDTA, and castor oil potassium soap into the reaction kettle in proportion and stir evenly to emulsify and stabilize Specifically, first add sodium hydroxide and stir for 3 minutes; then add EDTA and stir for 10 minutes; then add castor oil potassium soap a...

Embodiment 2

[0035] The present invention prepares the used raw material formula of 1 ton of concentrated solution as follows:

[0036] Element

[0037] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

[0039] The present invention prepares the used raw material formula of 1 ton of concentrated solution as follows:

[0040] Element

[0041] The preparation method of this embodiment is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com