A kind of high-strength low-modulus medical β-ti alloy material and preparation method thereof

A technology of alloy materials and low modulus, which is applied in the field of medical titanium alloys, can solve the problems of complex preparation process and achieve the effects of simple preparation process, convenient operation and high implantation success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

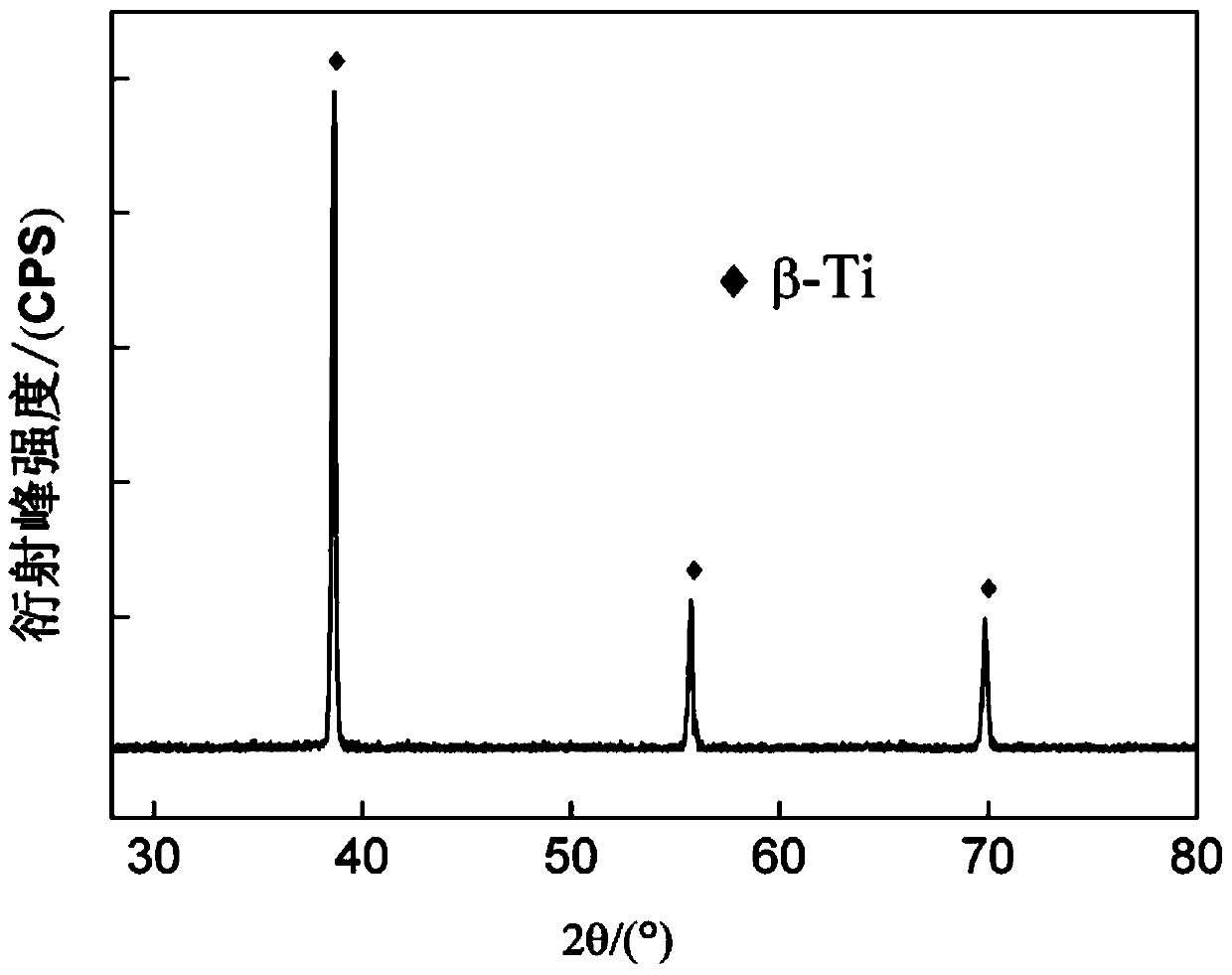

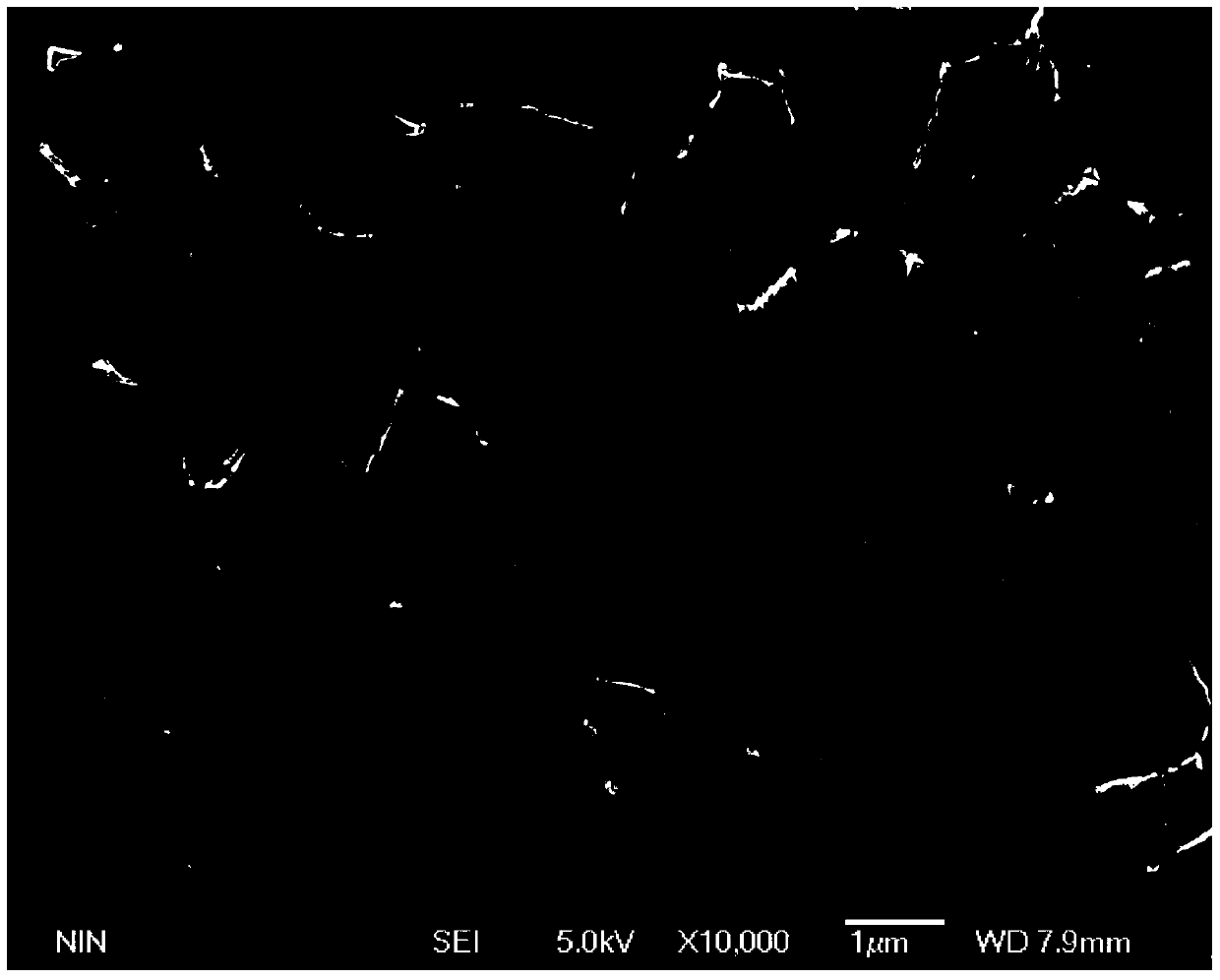

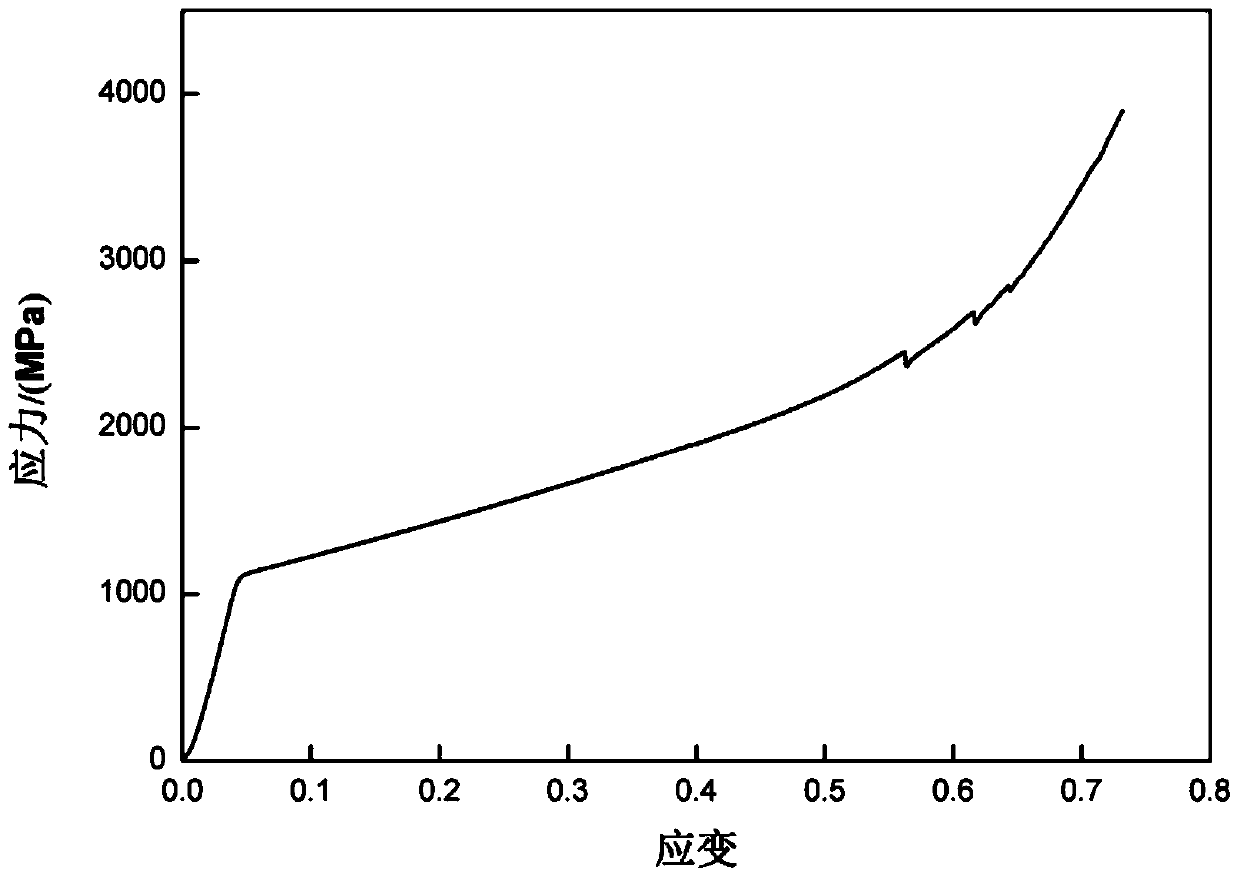

[0030] In this embodiment, a high-strength low-modulus medical β-Ti alloy material contains titanium, niobium, zirconium and indium in mass percentages of 68wt%Ti, 28wt%Nb, 2wt%Zr, 2wt%In, β - Ti alloy materials also contain unavoidable trace impurities.

[0031] The preparation method of the above-mentioned high-strength low-modulus medical β-Ti alloy material comprises the following steps:

[0032] (1) Powder mixing: According to the mass percentage of four elements of titanium, niobium, zirconium and indium in the β-Ti alloy material, the corresponding mass of elemental powder is weighed. Among the elemental powders, the purity of Ti, Nb, and In is 99.95%. %, the powder purity of Zr is 99.6%, and the average particle size of each elemental powder is about 45 μm; then each elemental powder is put into a V-type powder mixer and mixed evenly, and the mixing time is 5 hours to form a mixed powder;

[0033] (2) High-energy ball milling to prepare β-Ti alloy powder: put the mixe...

Embodiment 2

[0037] In this embodiment, a high-strength low-modulus medical β-Ti alloy material contains titanium, niobium, zirconium and indium in mass percentages of 64.2wt% Ti, 26.4wt% Nb, 1.9wt% Zr, and 7.5wt% respectively. %In, β-Ti alloy materials also contain unavoidable trace impurities.

[0038] The preparation method of the above-mentioned high-strength low-modulus medical β-Ti alloy material comprises the following steps:

[0039](1) Powder mixing: According to the mass percentage of four elements of titanium, niobium, zirconium and indium in the β-Ti alloy material, the corresponding mass of elemental powder is weighed. Among the elemental powders, the purity of Ti, Nb, and In is 99.95%. %, the powder purity of Zr is 99.6%, and the average particle size of each elemental powder is about 45 μm; then each elemental powder is put into a V-type powder mixer and mixed evenly, and the mixing time is 5 hours to form a mixed powder;

[0040] (2) High-energy ball milling to prepare β-T...

Embodiment 3

[0044] This embodiment is a high-strength low-modulus medical β-Ti alloy material, in which the mass percentages of the four elements of titanium, niobium, zirconium and indium are 62wt% Ti, 25.2wt% Nb, 1.8wt% Zr, and 11wt% In , β-Ti alloy materials also contain unavoidable trace impurities.

[0045] The preparation method of the above-mentioned high-strength low-modulus medical β-Ti alloy material comprises the following steps:

[0046] (1) Powder mixing: According to the mass percentage of four elements of titanium, niobium, zirconium and indium in the β-Ti alloy material, the corresponding mass of elemental powder is weighed. Among the elemental powders, the purity of Ti, Nb, and In is 99.95%. %, the powder purity of Zr is 99.6%, and the average particle size of each elemental powder is about 45 μm; then each elemental powder is put into a V-type powder mixer and mixed evenly, and the mixing time is 5 hours to form a mixed powder;

[0047] (2) High-energy ball milling to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com