A preparation method of flexible brain nerve electrode coating and assembled electrode

An electrode coating, brain technology, applied in the direction of coating, application, diagnostic recording/measurement, etc., can solve the problem of increasing the impedance of the metal electrode site, the coating is fragile, and it takes hours or even days, etc. To achieve the effect of reducing chronic inflammatory response, reducing acute inflammatory response, and good structural regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

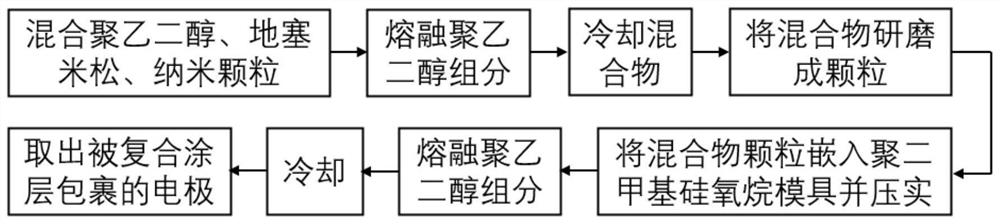

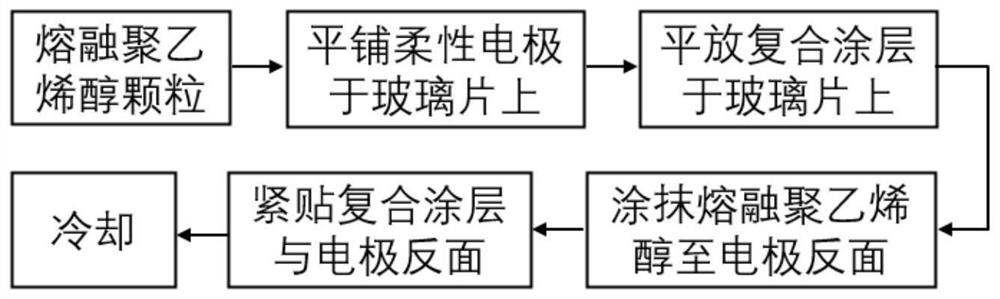

[0047] Such as figure 1 As shown in the flowchart, it operates in an operating room environment. The analytically pure polyethylene glycol with a viscosity average molecular weight of 10000g / mol, pharmaceutical grade dexamethasone, and polylactic acid-glycolic acid copolymer loaded pharmaceutical grade dexamethasone nanoparticles were mixed in a mass ratio of 7:2:1 inside the beaker. Subsequently, the mixture was heated on a hot plate at a temperature of 120° C. for 5 minutes, and after the polyethylene glycol component was melted, the mixture was stirred at a constant temperature for 10 minutes to uniformly mix the components. Subsequently, the mixture was left to cool at room temperature for 3 min. Subsequently, place the cooled mixture in a mortar and grind it into fine particles, and use a microscope to observe to ensure that the particle size is controlled between 0.2mm-0.5mm (too coarse particles are difficult to embed into polydimethylsiloxane mold needle-shaped insi...

Embodiment 2

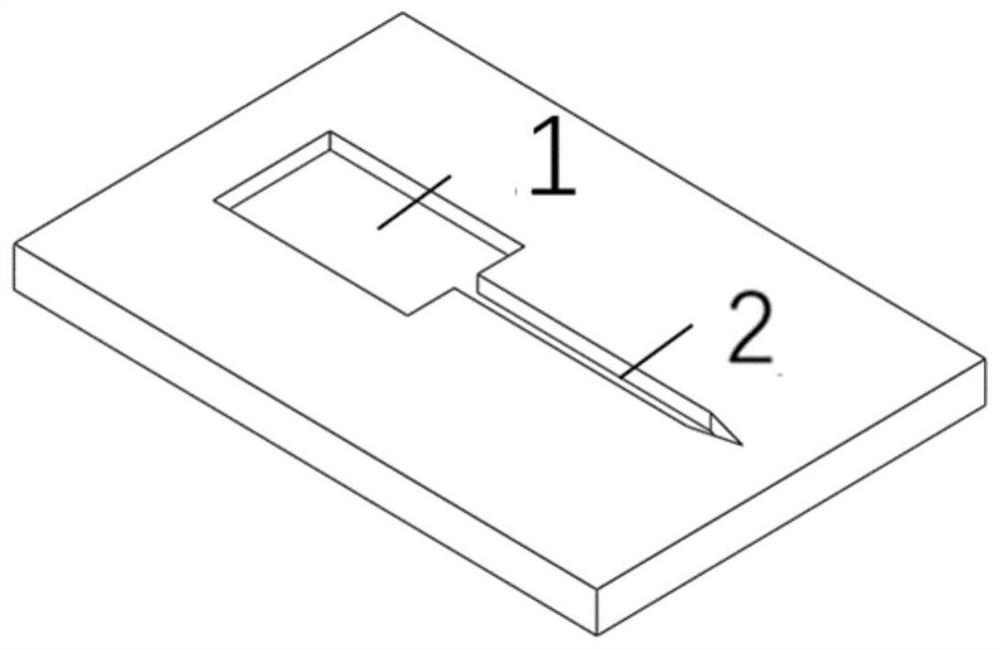

[0051] Such as figure 1 As shown in the flowchart, it operates in an operating room environment. The analytically pure polyethylene glycol with a viscosity average molecular weight of 20000g / mol, pharmaceutical grade dexamethasone, and polylactic acid-glycolic acid copolymer loaded pharmaceutical grade dexamethasone nanoparticles were mixed in a mass ratio of 8:1:1 inside the beaker. Subsequently, the mixture was heated on a hot plate at a temperature of 120° C. for 5 minutes, and after the polyethylene glycol component was melted, the mixture was stirred at a constant temperature for 10 minutes to uniformly mix the components. Subsequently, the mixture was left to cool at room temperature for 3 min. Subsequently, the cooled mixture is ground into fine particles in a mortar and observed with a microscope to ensure that the particle size is controlled between 0.2 mm and 0.5 mm. Use tweezers to embed the granular mixture as figure 2 The needle-shaped flow channel 2 of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com