Combined box culvert for jacking construction method and making method thereof and raw material thereof

A construction method and combined technology, applied in artificial islands, manufacturing tools, water conservancy projects, etc., can solve the problems of poor waterproof effect of box culverts, low space utilization, unreasonable force, etc., to achieve high space utilization and production Low cost, ensure no cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

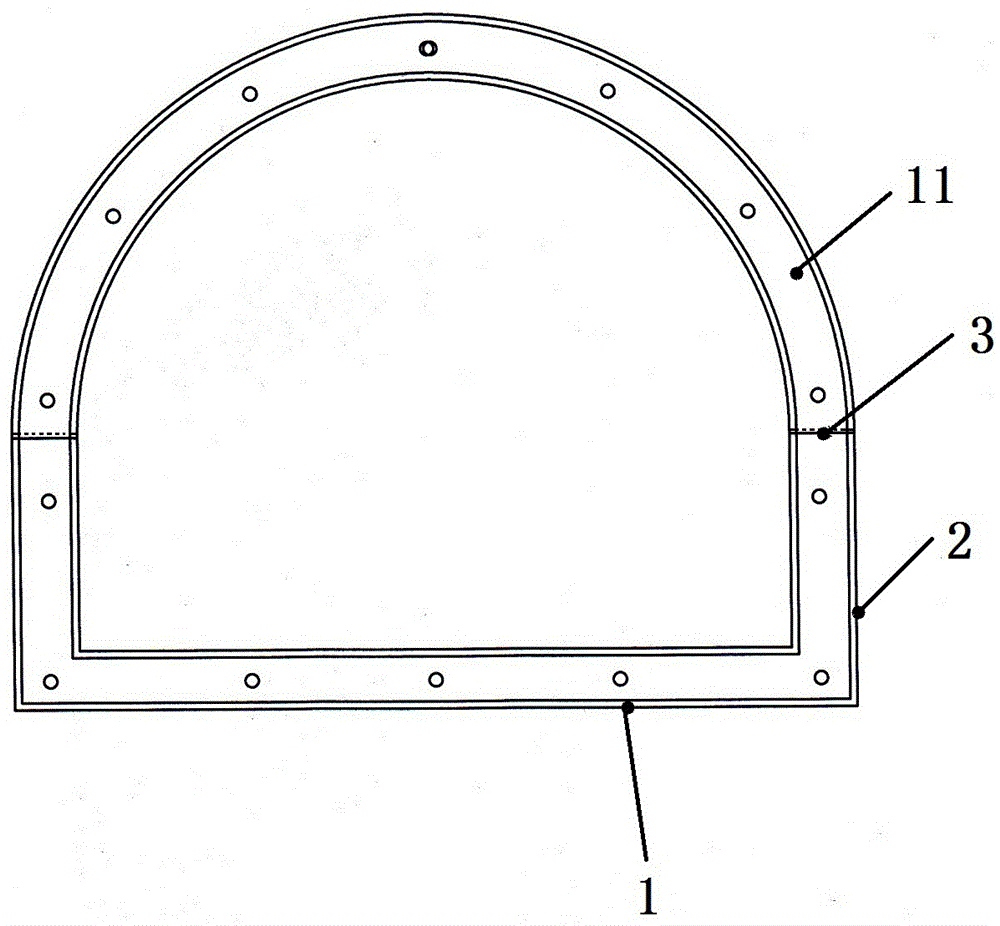

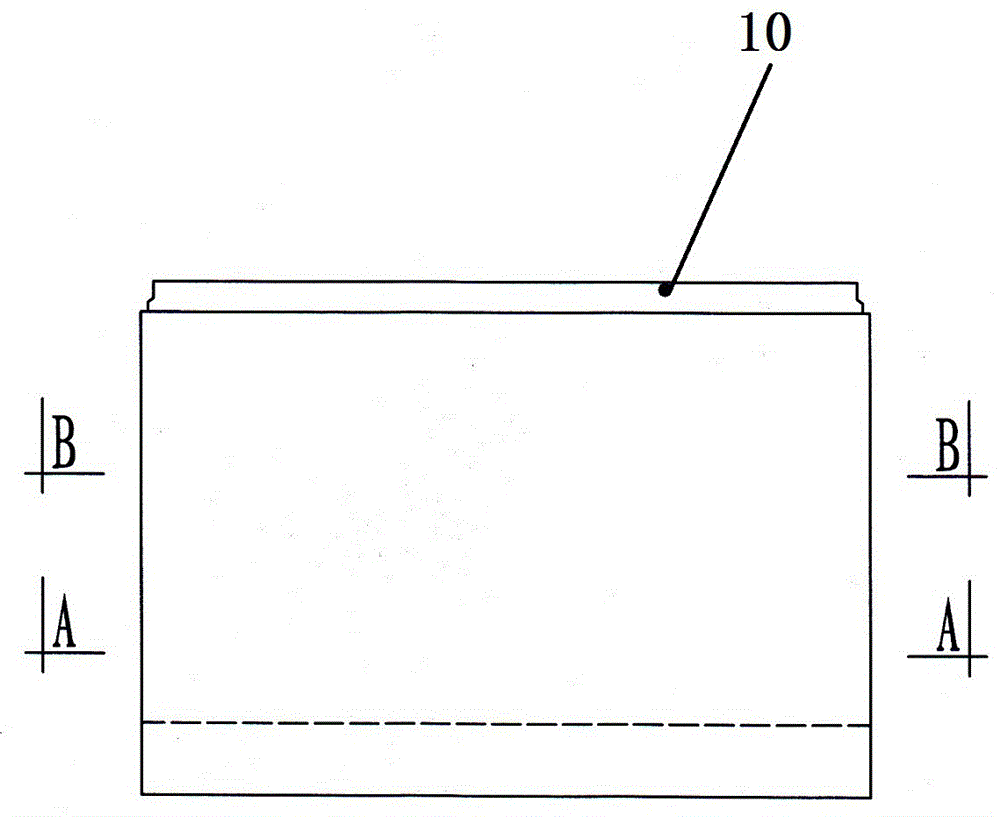

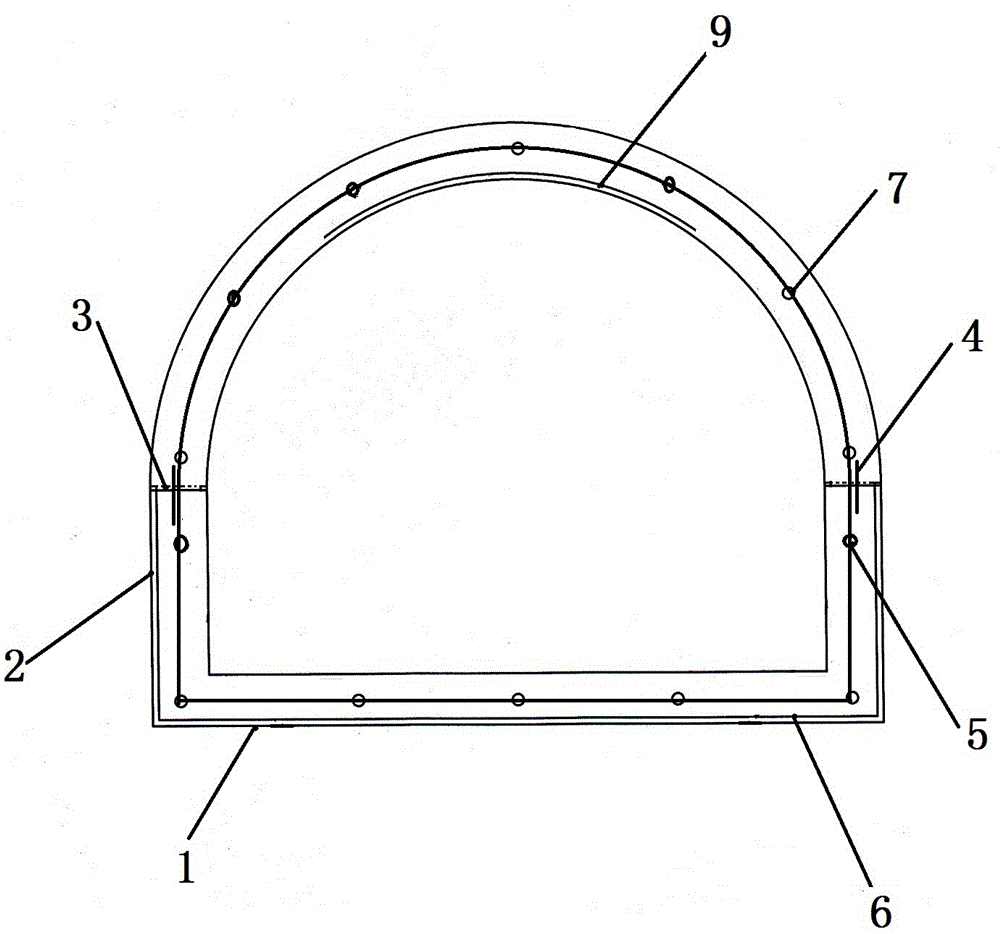

[0023] The combined box culvert includes a base with a grooved section and an arched dome with an arched section. The base includes a bottom plate 1, and two side plates 2 are respectively fixed on both sides of the bottom plate. Water-expandable rubber strips 3 are provided on the surface, and several embedded steel bars 4 are arranged in the two side panels. There is a base reinforcement frame 5 with a grooved section and a waterproof steel plate 6 with a grooved section;

[0024] The vault is wrapped with a vault steel skeleton 7, the compression area inside the vault is provided with a long thin steel plate 8, the tension area inside the vault is provided with a crack-resistant steel mesh 9, and the vault is placed on two sides of the corresponding base. The pre-embedded steel bars of the side panels are provided with reserved holes, and the second-generation construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com