Assembly-type protective construction method for slab-pile wall through pre-stressed anchor cables

A technology of prestressed anchor cables and construction methods, which can be applied to sheet pile walls, artificial islands, water conservancy projects, etc., and can solve the problems of cumbersome operations such as formwork support, formwork removal, maintenance, grouting and anchor bolt setting, and high labor costs. To solve the problem, to achieve outstanding economic benefits, reduce construction time, and increase the effect of pile side friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In this embodiment, the prefabrication process requirements for pile-slab walls and pipe piles, the technical requirements for prestressed anchor cable tensioning construction, and the construction process requirements for concrete pouring will not be described in detail, and the prestressed anchor cable assembled piles involved in the present invention will be focused on. The implementation mode of the construction of the board wall protective structure.

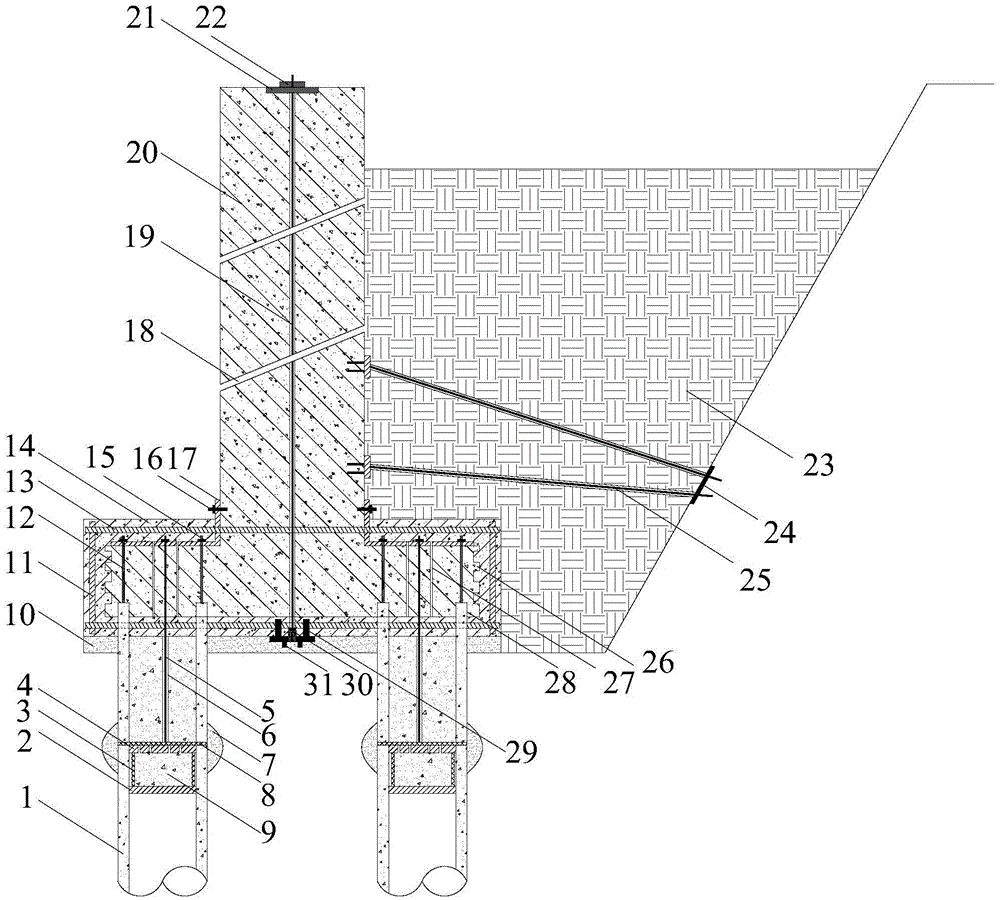

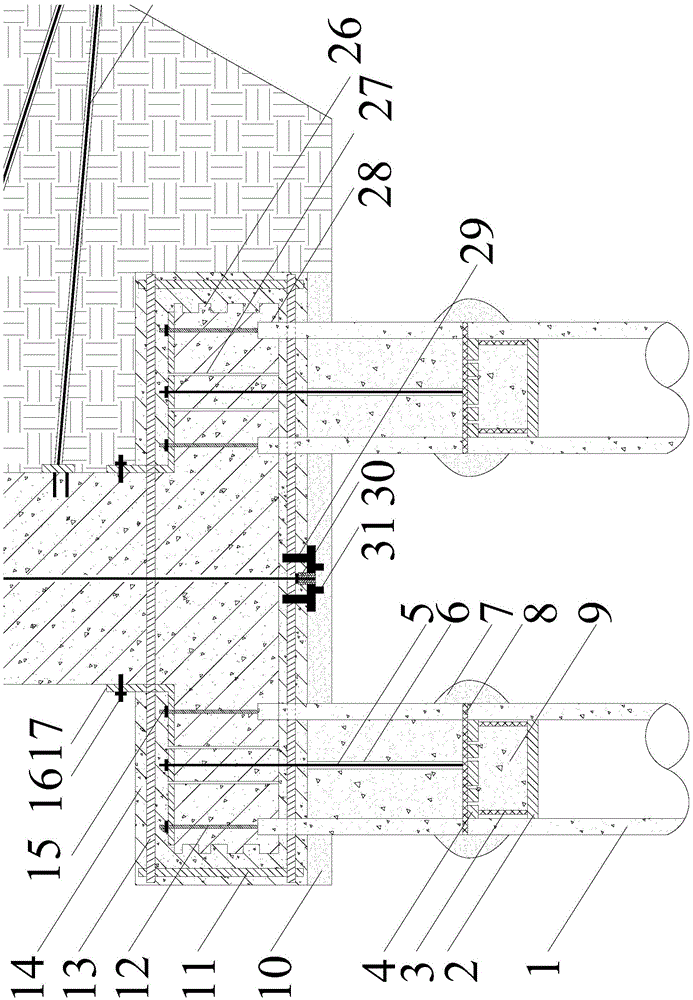

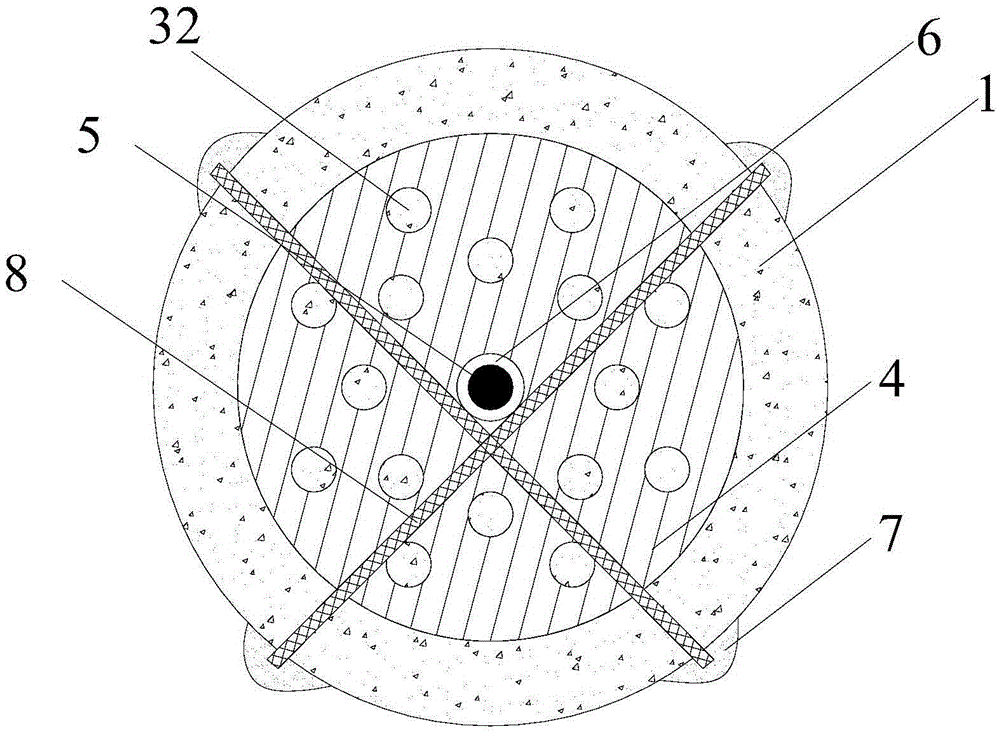

[0028] refer to figure 1 The prestressed anchor cable assembled pile-slab wall protective structure mainly consists of prefabricated pipe pile 1, prefabricated pile-slab wall 20, prestressed anchor cable 19 inside the wall, post-cast foundation 14, prestressed anchor cable 25 on the filling side, etc. composition.

[0029] Before the construction, the original slope shall be treated first, the exposed stones and sundries affecting the construction shall be removed, and it shall be trimmed into a flat surface, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com