High-frequency electromagnetic induction heating device

An induction heating device and high-frequency induction heating technology, applied in the field of high-frequency electromagnetic induction heating devices, can solve the problems of low heat utilization rate, poor crude oil heating effect, large energy consumption, etc., and achieve the effect of high efficiency and easy automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

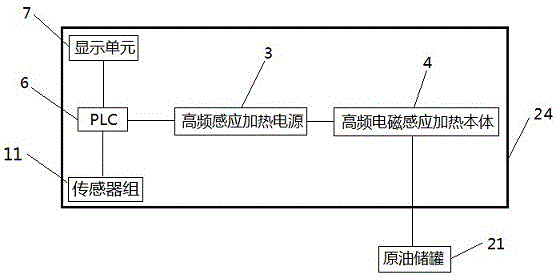

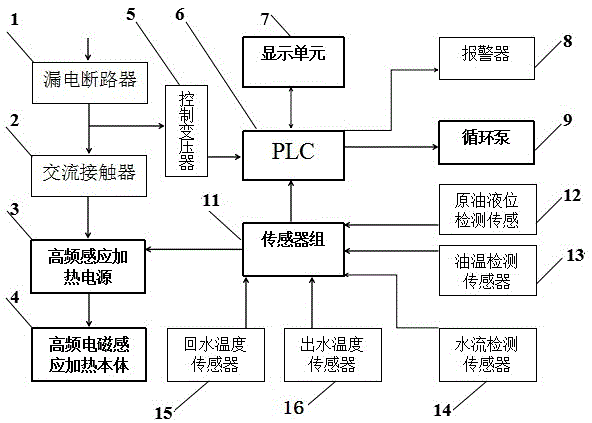

[0024] Such as figure 1 As shown, the present embodiment provides a high-frequency electromagnetic induction heating device, including a heating cabinet 24, and the heating cabinet 24 is provided with a PLC 6 electrically connected in sequence, a high-frequency induction heating power supply 3, a high-frequency electromagnetic induction heating body 4, and The display unit 7 and the sensor group 11 electrically connected to the PLC6, the high-frequency electromagnetic induction heating body 4 are connected to the crude oil storage tank 21 to be heated through the pipeline, and the PLC6 controls the high-frequency electromagnetic induction heating body 4 to be energized or energized through the high-frequency induction heating power supply 3 power off.

[0025] When the temperature in the pipeline is lower than 0°C, the PLC6 controls the high-frequency electromagnetic induction heating body 4 to be energized through the high-frequency induction heating power supply 3, and the h...

Embodiment 2

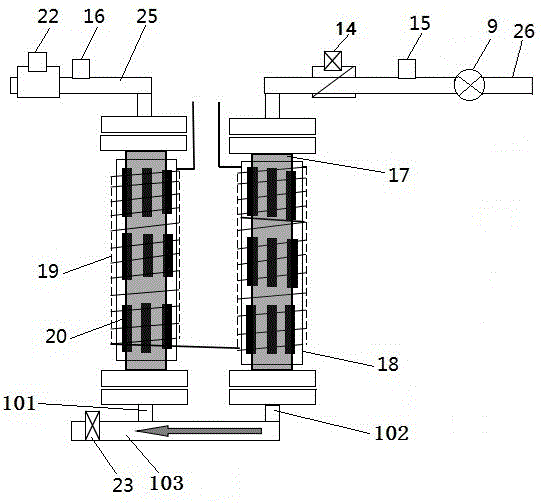

[0029] On the basis of Example 1, such as image 3 As shown, the high-frequency electromagnetic induction heating body 4 includes two electromagnetic induction heating pipes 17, one end of one electromagnetic induction heating pipe 17 communicates with the water outlet pipe 25, the other end communicates with the first vertical pipe 101, and the other end of the electromagnetic induction heating pipe 17 communicates with the first vertical pipe 101. One end of the magnetic induction heating pipe 17 is communicated with the return pipe 26, and the other end is communicated with the second vertical pipe 102, and the ends of the first vertical pipe 101 and the second vertical pipe 102 away from the electromagnetic induction heating pipe 17 are connected with the horizontal pipe 103 connected, the horizontal pipe 103 is connected in series with an emptying valve 23, the return pipe 26 is connected in series with a circulation pump 9, the outlet pipe 25 and the return pipe 26 extend...

Embodiment 3

[0033] On the basis of Embodiment 2, the sensor group 11 includes an outlet water temperature sensor 16, a water flow detection sensor 14 and a return water temperature sensor 15, the outlet water temperature sensor 16 is installed on the outlet pipe 25, the water flow detection sensor 14 and the return water temperature sensor 15 are all installed on the return water pipeline 26, the return water temperature sensor 15 is installed between the water flow detection sensor 14 and the circulation pump 9, the outlet water temperature sensor 16, the water flow detection sensor 14, the return water temperature sensor 15 are all connected with PLC6, high frequency induction The heating power supply 3 is electrically connected. The sensor group 11 also includes a crude oil level detection sensor 12 and an oil temperature detection sensor 13 installed in the crude oil storage tank 21. electrical connection. A safety pressure limiting valve 22 is connected in series on the outlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com