Integral MFL (Magnetic Flux Leakage) and eddy current array sensor for detecting copper-coated/aluminum-coated steel shaft type structure

An eddy current sensor, aluminum-clad steel technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., to achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, and the following examples are only descriptive but not restrictive, and cannot limit the protection scope of the present invention.

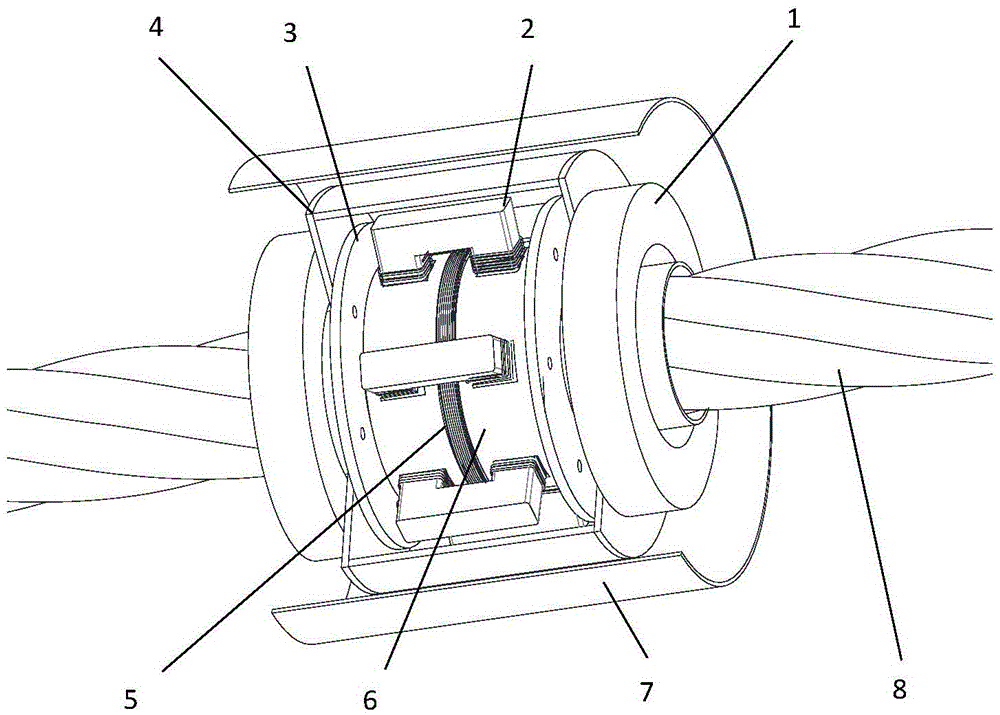

[0020] figure 1 Schematic diagram of the structure of the magnetic flux leakage and eddy current integrated array sensor for detecting copper or aluminum-clad steel shaft structures.

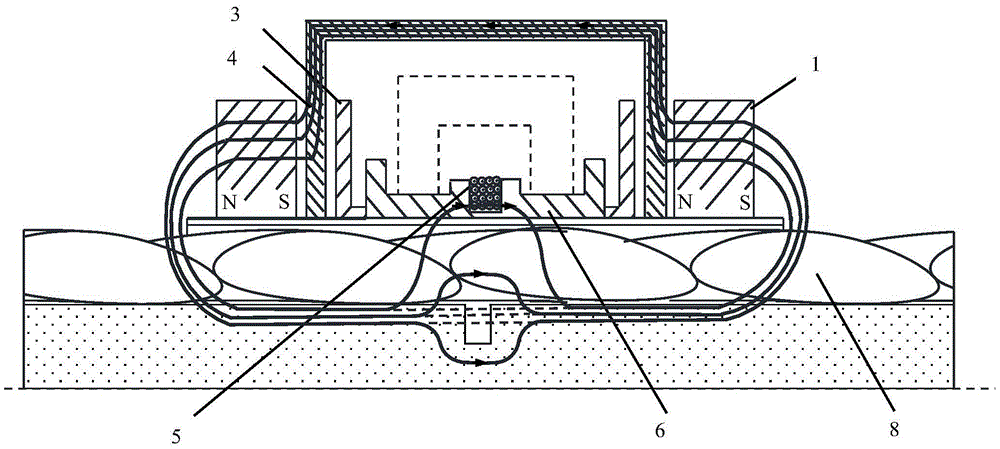

[0021] figure 2 Schematic diagram of the working principle when implementing magnetic flux leakage detection for the sensor. The magnetic flux leakage detection part is composed of an annular permanent magnet 1 and a magnetic flux leakage induction coil 5. When the sensor is nested on the measured component 8, the axial bias magnetic field provided by a pair of coaxial annular permanent magnets 1 will act on the measured component 8 to be magnetized. If there is a defect in the ferromagnetic steel core or steel strand in the test piece, the leakage magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com