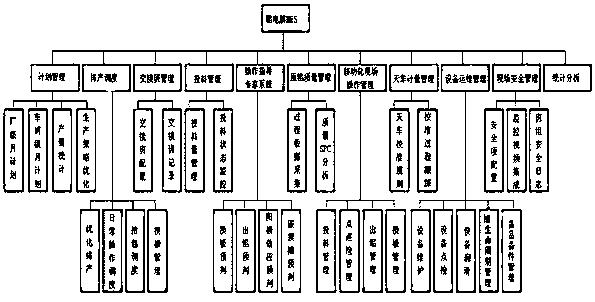

A precise perception and intelligent decision-making method and mes system for aluminum electrolytic production

A technology of intelligent decision-making and production management system, applied in the field of aluminum electrolysis production management and control system, can solve problems such as no standardized products and solutions, no promotion value, and many uncertain factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

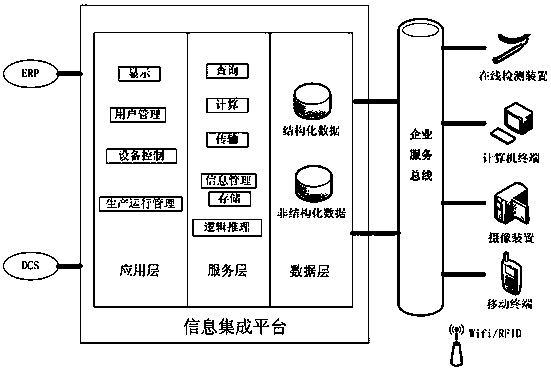

Embodiment 1

[0057] Embodiment 1: the present invention adopts existing industrial Ethernet technology and Wi-Fi technology to construct wired network and wireless network, adopts Windows operating system, SQL database and Chinese Academy of Sciences software institute real-time database, has set up information integration platform; Adopt Chinese Academy of Sciences Shenyang automation The developed MES system middleware SIA-MES, the SIA-MES system is used as the basic platform and application suite, and the application module is developed; the current distribution, temperature distribution, interface The online detection device for shape detection and concentration distribution detects the production data of the electrolyzer and the production data of the whole plant online, and transmits them to the application system through the information integration platform; RFID is used to collect worker location information, and IPAD is used as an intelligent mobile terminal to input on-site product...

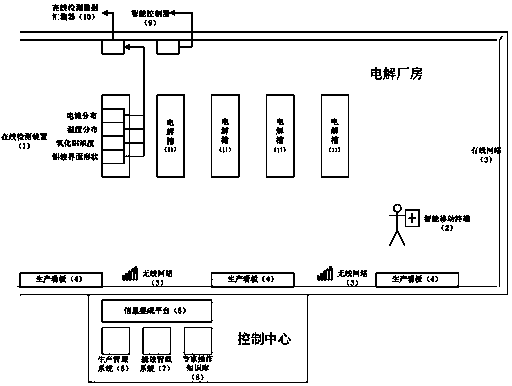

specific Embodiment approach

[0058] The specific implementation method is as follows: use the electrolyzer online detection device 1 and the intelligent mobile terminal 2 to detect the production data of the electrolyzer online, obtain the production data and personal location information of the whole factory in real time, and upload them to the information integration platform 5 through the wireless or wired network 3 in the factory area. Through the production management system 6 based on the real-time data of the production process, based on the analysis of tank conditions, costs, quality, and energy efficiency, the production strategy, production plan, production scheduling and scheduling, operation guidance, performance appraisal, equipment maintenance, and energy efficiency scheduling are given. and other decisions, and through the intelligent mobile terminal 2 and the production kanban 4, it is transmitted to the managers and operators in the form of data, video, and images to guide the operation; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com